01

Zirconia Ball for Bead Mill Grinding Media Ball

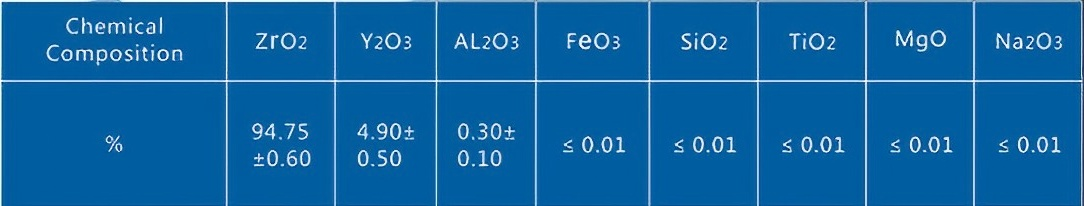

Chemical Composition

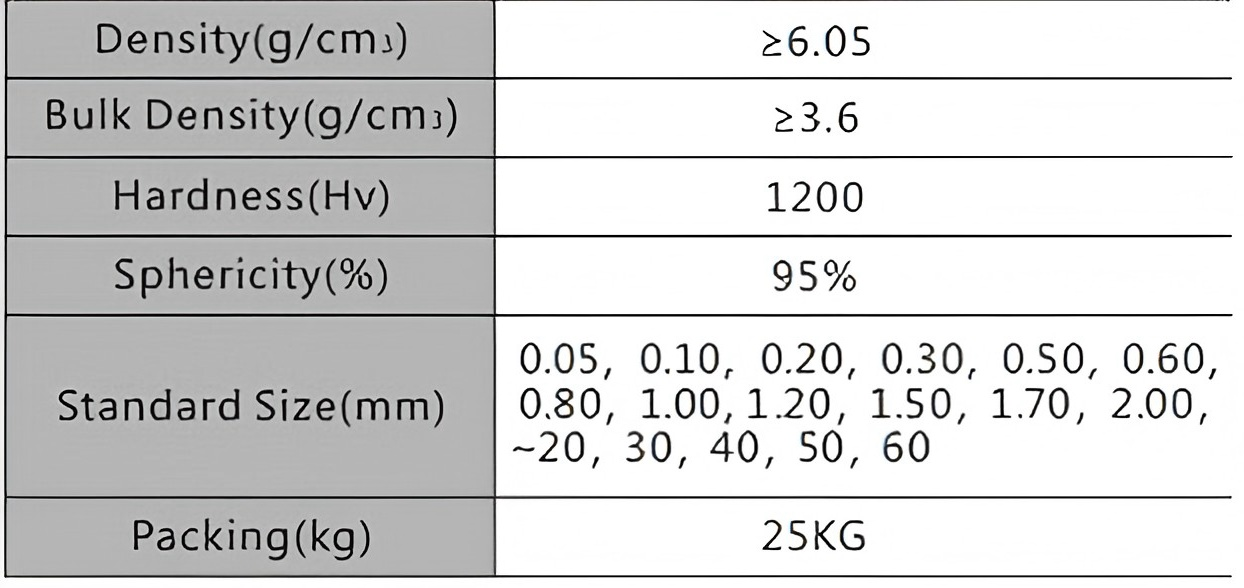

Physical Properties

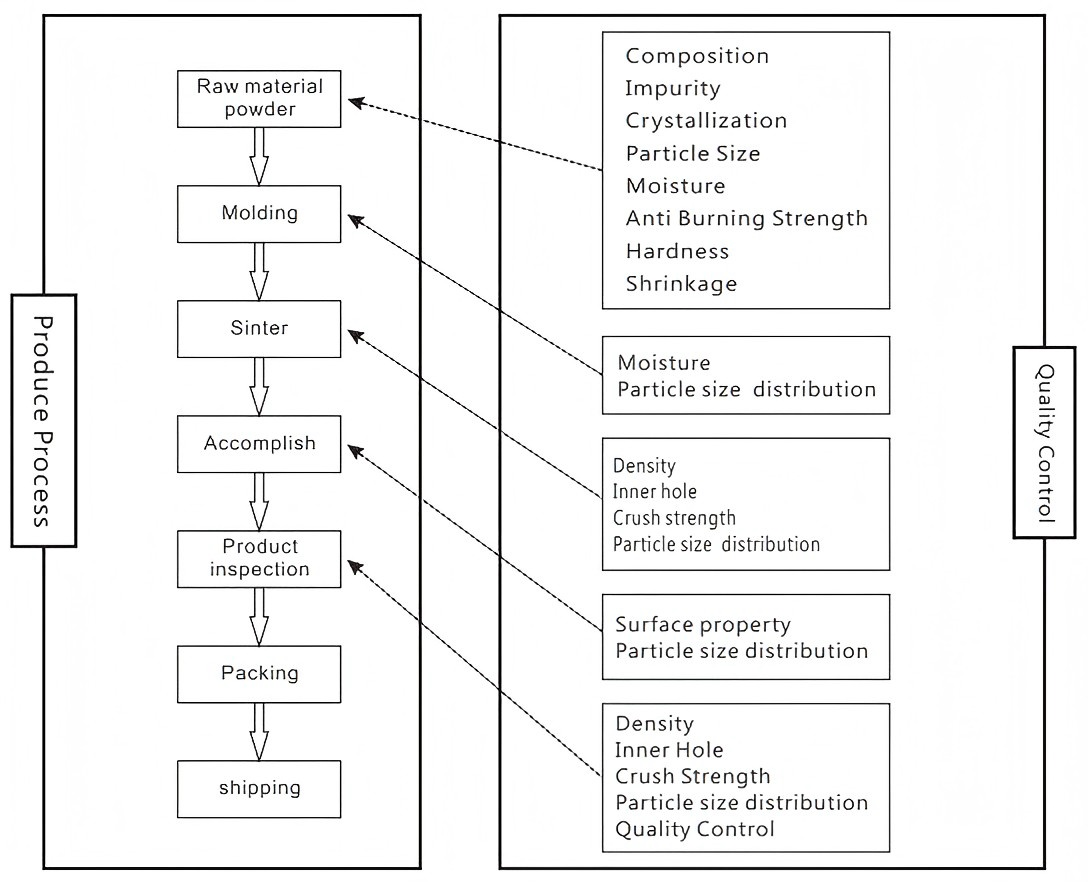

Produce Process

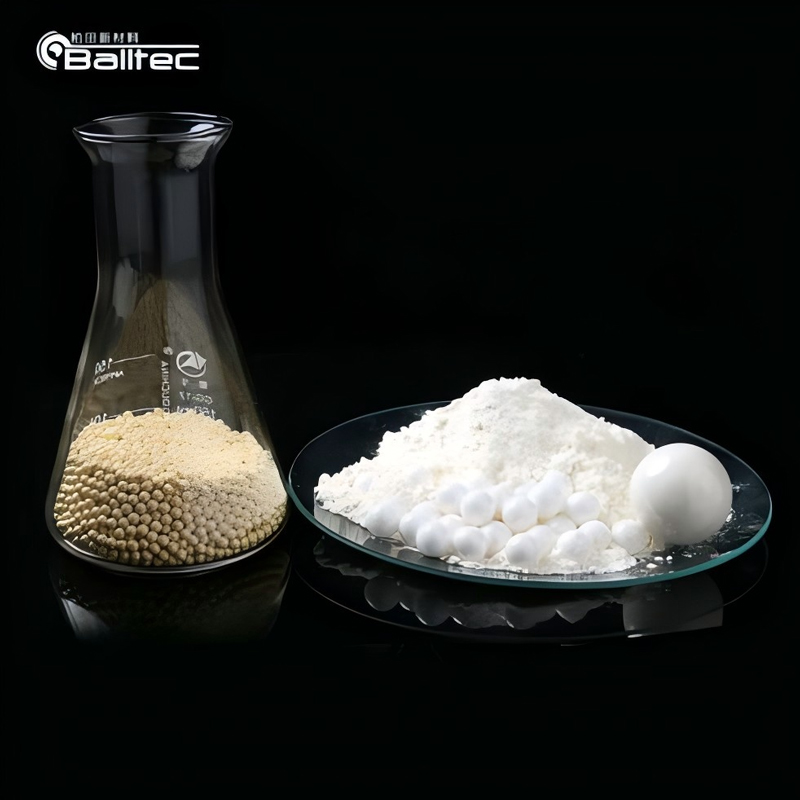

Yttrium stabilized zirconia beads:

name as zirconia ball, 95 zirconia ceramic bead, zirconium bead, ultra-fine grinding medium, zirconia micro sphere, zirconia grinding ball, zirconia grinding media.

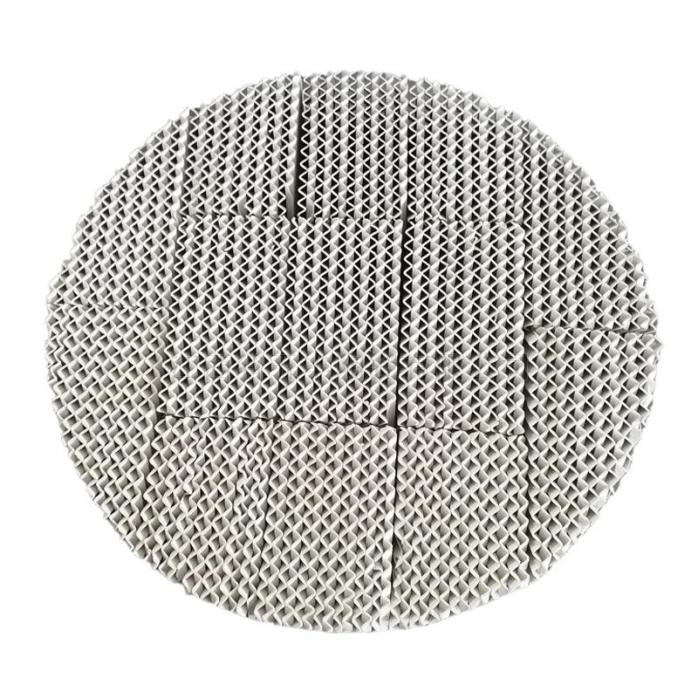

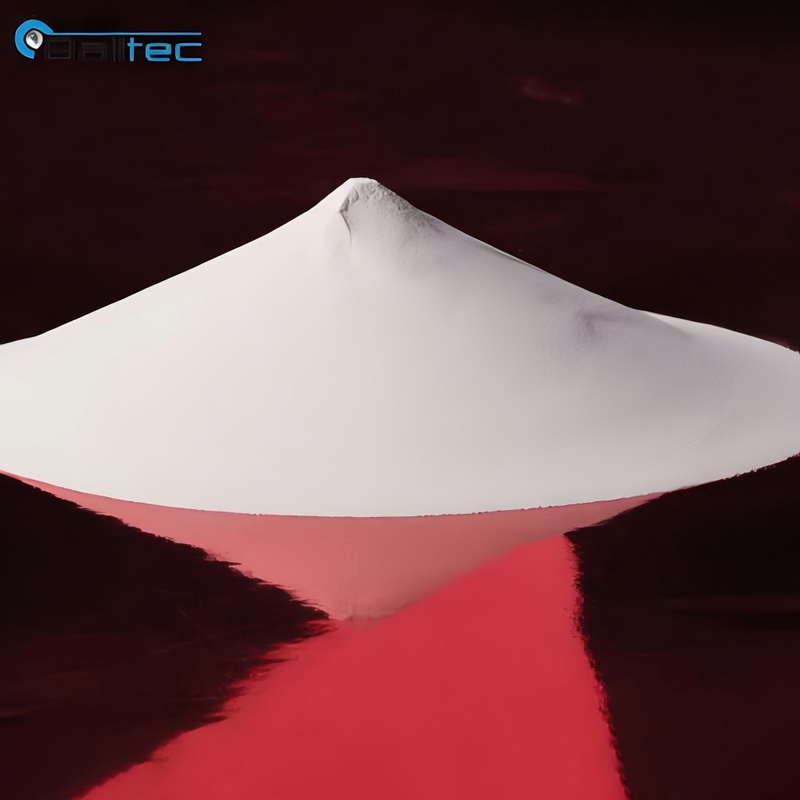

It has a pearl luster and smooth working sphere, dense internal structure, super high densiry , strong compressive strength and super high wear resistance, and is a high-end product in abrasive media. However, this product has a high requirement for the use of the hardness of the memory material in the grinding machine.

Yttrium Stabilized Zirconia beads (95 Zirconia/Pure Zirconia beads)

Features: Zirconia content is close to 95%, with high whiteness, high fineness and excellent chemical stability, to ensure that the grinding process does not pollute the material.

Application: Mainly used in high-end fine grinding fields, such as food, medicine, cosmetics and other industries with high purity requirements, commonly used in sand mills for ultra-fine grinding.

Usage: Due to its high purity and high hardness, it is necessary to choose the appropriate sanding model number, and adjust the grinding parameters according to the characteristics of the material. Check the grinding effect regularly and replace the severely worn beads timely.

Yttrium stabilized zirconia ball is the grinding medium corresponding to water vapor.

In the presence of water vapor, zirconia balls are prone to low temperature aging and cracking. Adding a certain proportion of yttrium oxide to it can solve similar problems.

Yttrium stabilized zirconia balls have strict requirements for raw material purity, ratio, firing temperature and production process, and the finished products have consistent uniform quality inside and outside.

With pearl-like luster and smooth working sphere, it is the best of the grinding media. At present, many similar products on the market rely on long-term polishing to obtain a brighter surface, but after a long time of use, the surface bright layer is destroyed after aging, and the performance is greatly reduced.