01

Zirconia Alumina Composite Bead/ZTA Bead/Ceramic Grinding Beads for Mine

Feature & Application

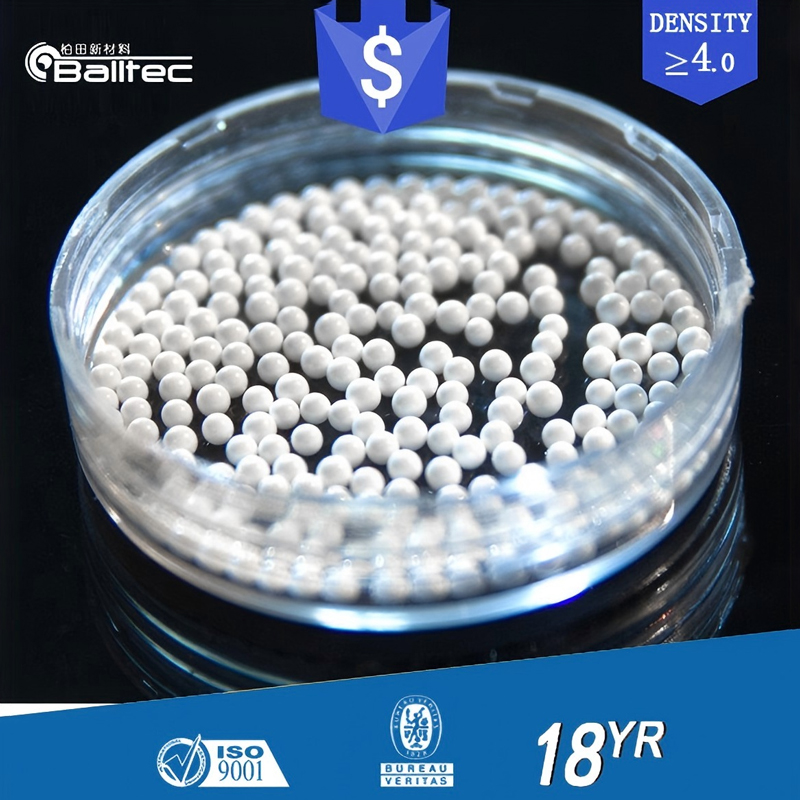

With special process, the internal structure of the beads is uniform and compact.

A wide range of applications,especially grinding materials with high hardness.

Good stability, strong acid&alkali resistance.

High density, significantly improving grinding efficiency.

It keeps high grinding kinetic energy and reduces the amount of loading.

Application

It is suitable for grinding and dispersing all kinds of vertimill, vertical, horizontal sand mill, ball mill and other equipment. It is the first choice that substitution performance to price ratio of yttria stabilized zirconia beads.

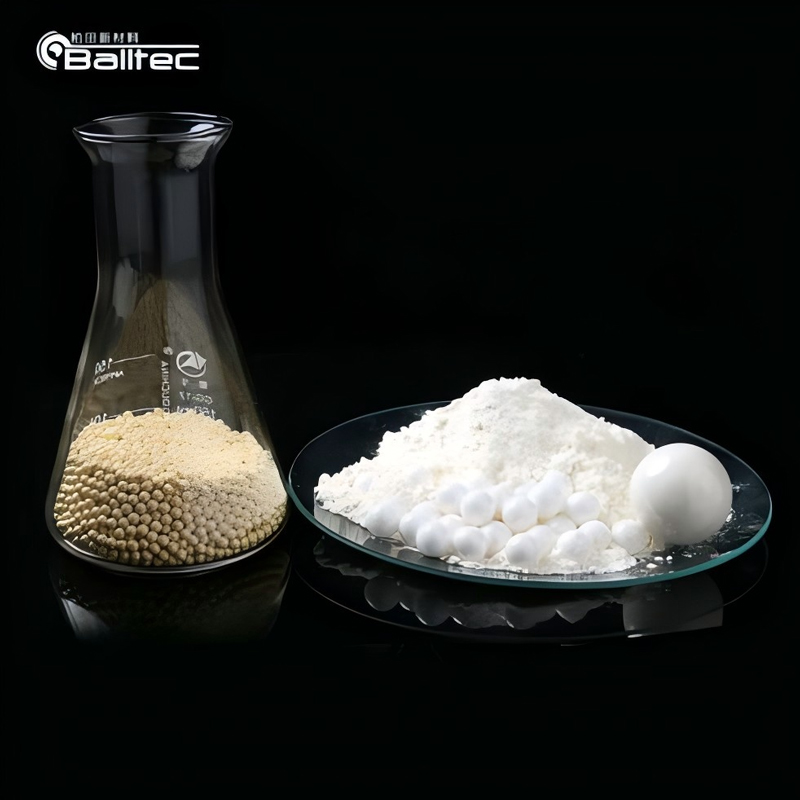

Chemical Content

ZrO2: 85 %; AL2O3:15%

ZrO2: 15 %; AL2O3:85%

Physical Properties

Density(g/cm3):5.4

BulkDensity(g/cm3):3.2

Hardness(Hv):1200

Sphericity(%):99%

Standard Size(mm): 0.50,0.60, 0.80, 1.00, 1.20, 1.50,1.70,2.00,~10mm

Packing(kg): 25kg Plastic Drum

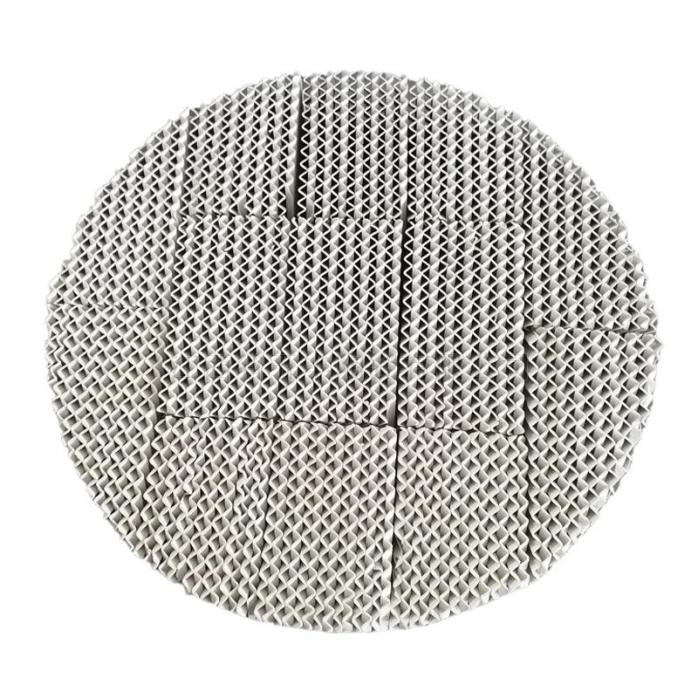

The composite zirconium bead NanorZr-10 is made by a unique rolling forming process with alumina as the main material and zirconia as the toughening auxiliary material. Dense zirconium toughened alumina composite particles constitute the microstructure of the beads, and the performance has a qualitative leap, suitable for disc sander (grinding machine) to disperse and grind medium and low viscosity materials, for the economic zirconium series grinding medium, especially suitable for the dispersion and grinding of non-mineral metal materials.

Special points

Compared with alumina microbeads, the structure of composite zirconium beads is a composite crystal phase of zirconium oxide and alumina, which is more delicate and dense than the simple alumina microcrystals, so the wear is low. At the same time, the smooth sphere effectively reduces the power consumption and wear to the equipment contacts.

Product features

1.The internal crystal phase is uniform, the grain is fine, the structure is more reasonable

2.The roundness is good, the particle size is reasonable

3.High specific gravity, optimize grinding efficiency

4.No empty beads, low wear, longer service life

5. The surface is more smooth and bright