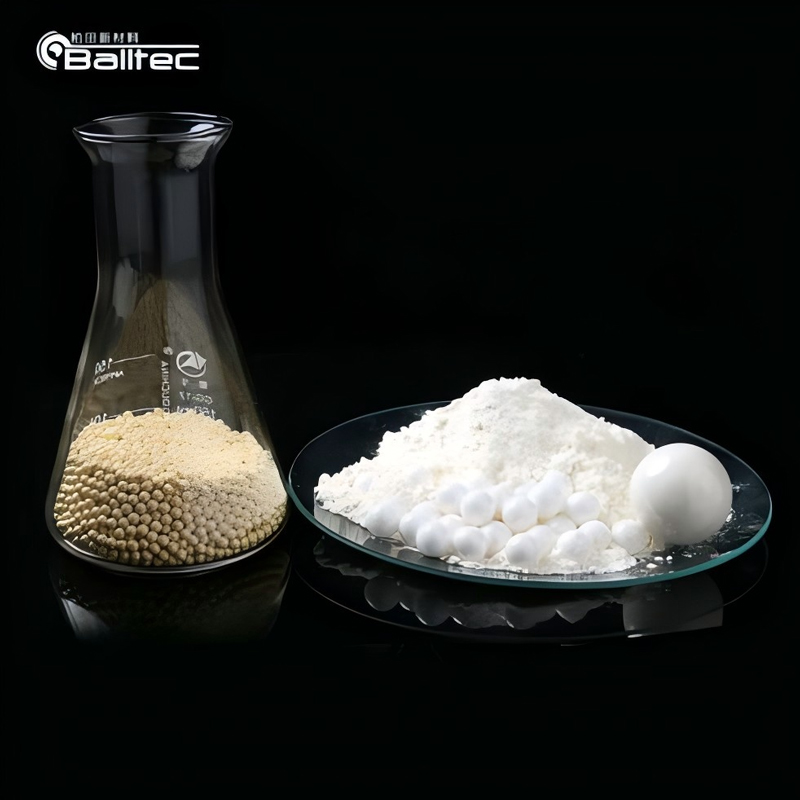

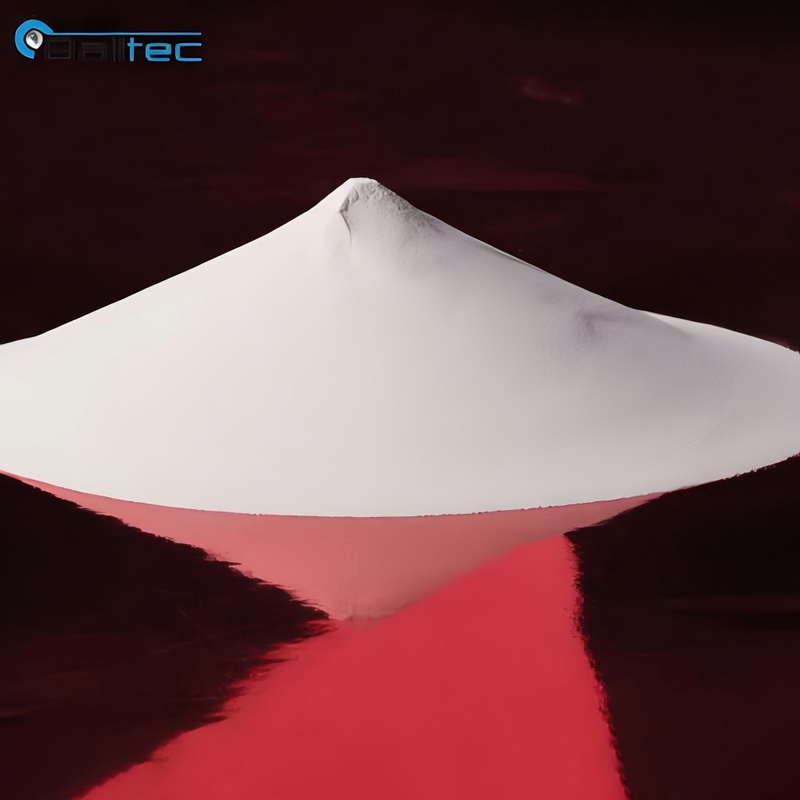

Wear & Heat Resistant Ceramic Structured Packing

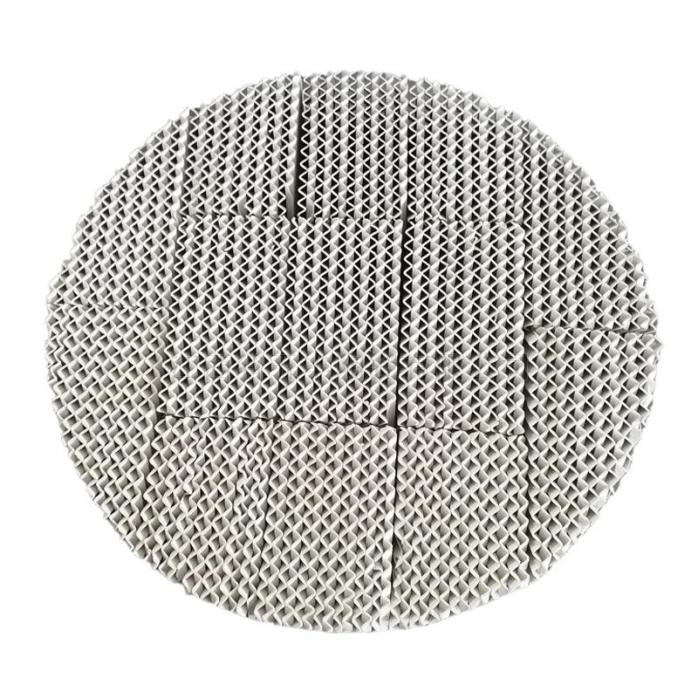

Depending on the different vertical inclination angles of the corrugated plates, the corrugated plate packed materials can be classified into two major types: X-type and Y-type. Among them, the inclination angle of the X-type corrugated plates is set at 30°, while that of the Y-type is 45°. These two types of packed materials have their own advantages in performance: the X-type is favored for its lower pressure drop, while the Y-type is highly regarded for its excellent mass transfer performance. If one needs to optimize both pressure drop and mass transfer performance simultaneously, holes can be ingeniously opened on the plates. Moreover, regular packed materials are widely used in the petrochemical field, such as in distillation, stripping, absorption, and extraction processes for mass transfer. Their unique surface roughness and corrosion resistance make them perform well in these applications, and there is no obvious size amplification effect.

The regular packing materials have demonstrated numerous advantages in the application of the petrochemical industry. Their unique surface roughness and corrosion resistance enable them to perform exceptionally well in processes such as distillation, stripping, absorption, and extraction, without any significant size amplification effect. Moreover, by ingeniously creating holes on the plates, the pressure drop and mass transfer performance can be simultaneously optimized, further enhancing their application effectiveness.

High flow rate: The newly designed tower structure can reduce the tower diameter, and the old tower can also significantly enhance the processing capacity through renovation.

High separation efficiency: Compared with loose packed materials, it has a larger specific surface area, thereby significantly improving the separation efficiency.

Low pressure drop: It can significantly save energy, provide a flexible operating range, and the scaling effect is not obvious.

Wide applicability: Regardless of the tower diameter size, this filler can be effectively applied.

Strong corrosion resistance: It can resist acids, alkalis, especially H2S, naphthenic acids and chloride ions.