01

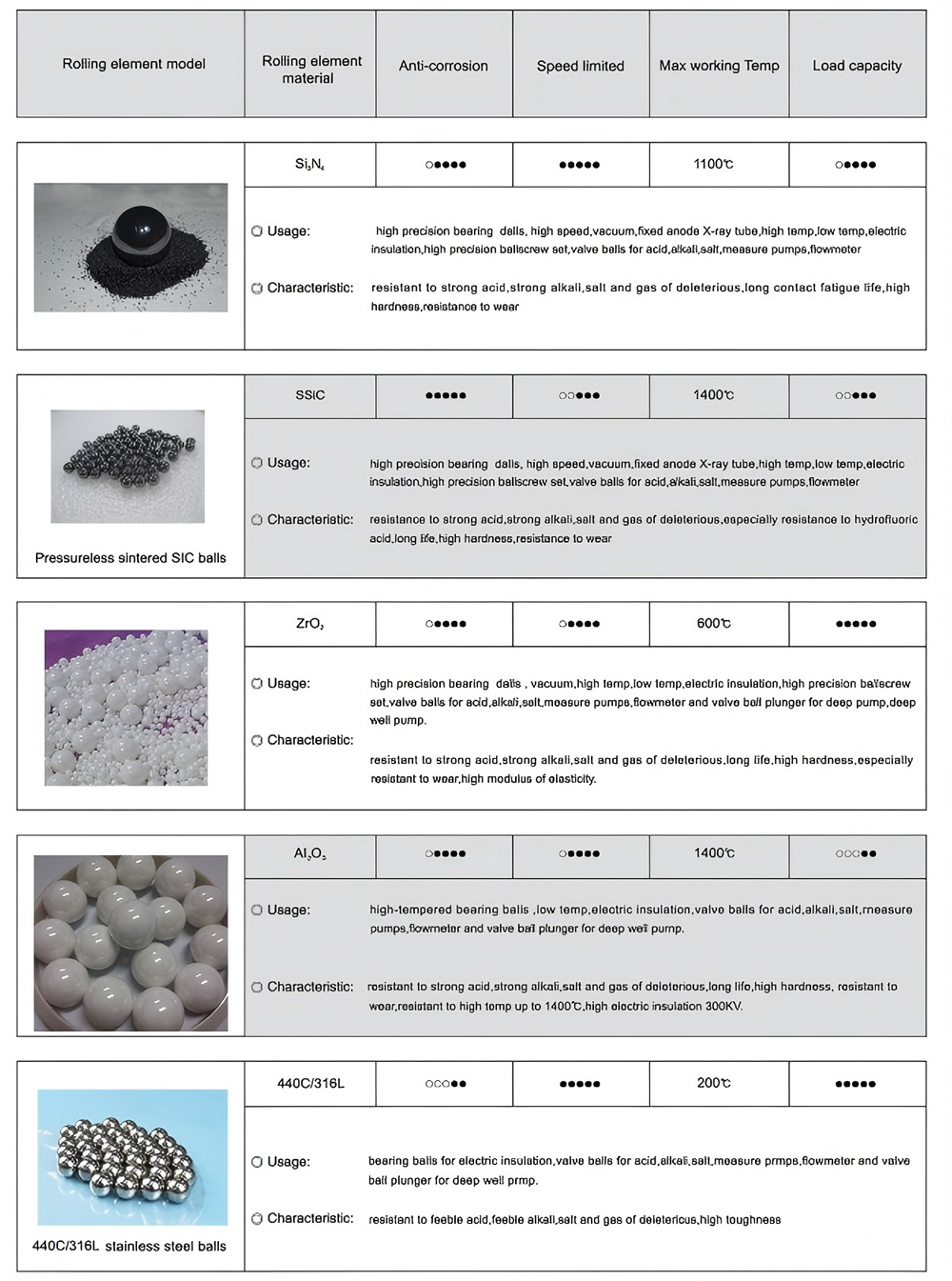

Silicon Nitride Ceramic Bearing Ball

Physical Properties

|

Item |

Density |

Coefficient |

Elasticity Modulus |

Poisson’s Ratio |

Hardness (HV) |

Hardness (HRC) |

Bending Strength |

Compressive Strength |

|

Unit |

g/cm3 |

10-6/k |

Gpa |

Mpa |

Mpa |

|||

|

Si3N4 |

3.23 |

3.2 |

300-320 |

0.26 |

1500-1800 |

75-80 |

200 |

1400 |

|

Item |

Fracture Toughness |

Thermal Conductivity |

Electrical Resistivity |

Highest Temp |

Acid and Alkali Corrosion resistance performance |

Stress Cycles (50% failure probalility) |

||

|

Unit |

Mpa·m1/2 |

W/mk |

Ω·mm2/m |

℃ |

Strong |

Times |

||

|

Si3N4 |

6.0-7.0 |

18 |

1018 |

800 |

107-109 |

|||

|

Item |

Dimensions stability |

Certrifugal Force |

Non-lubrication Friction |

Magnetism |

Rolling contact Fatigue Failure mode |

|||

|

Unit |

||||||||

|

Si3N4 |

With the temp,change is Small |

small |

small |

None |

Peel Off |

|||

Comparison

Silicon nitride bearing hardness is very good, the following is the details of its hardness and characteristics:

Hardness value: The hardness of silicon nitride bearings can reach a very high level. For example, the Vickers hardness of silicon nitride ceramic balls can reach 15-16Gpa, while the Rockwell hardness of silicon nitride is usually between 1800-2200, which makes its hardness far exceeding that of traditional metal bearings.

Hardness and material properties: The high hardness of silicon nitride is mainly due to its crystal structure similar to diamond, as well as the effect of preparation process and grain size. Under the condition of excellent technology, the prepared silicon nitride material has good crystallinity and clear grain boundary, which makes the hardness of silicon nitride higher. In addition, the finer the grain size of silicon nitride, the higher its hardness.

Hardness and practical application: The high hardness of silicon nitride bearings makes them widely used in many industries. For example, in the automotive industry, silicon nitride bearings can withstand the challenges of high-speed rotation and high temperature environments, and their hardness can reach 2000Hv, much higher than that of metal bearings. This high hardness allows the silicon nitride bearing to resist wear and thermal expansion during braking, thereby extending the life of the brake system.

Hardness and wear resistance: The hardness of silicon nitride bearings is closely related to wear resistance. Due to its high hardness, silicon nitride bearings can significantly reduce wear and extend service life during use. This makes silicon nitride bearings ideal for many applications requiring high wear resistance.

In summary, the hardness of silicon nitride bearings is very high, which is one of its important characteristics as a high-performance material. This high hardness makes silicon nitride bearings have a wide range of application prospects in many industries.