Products

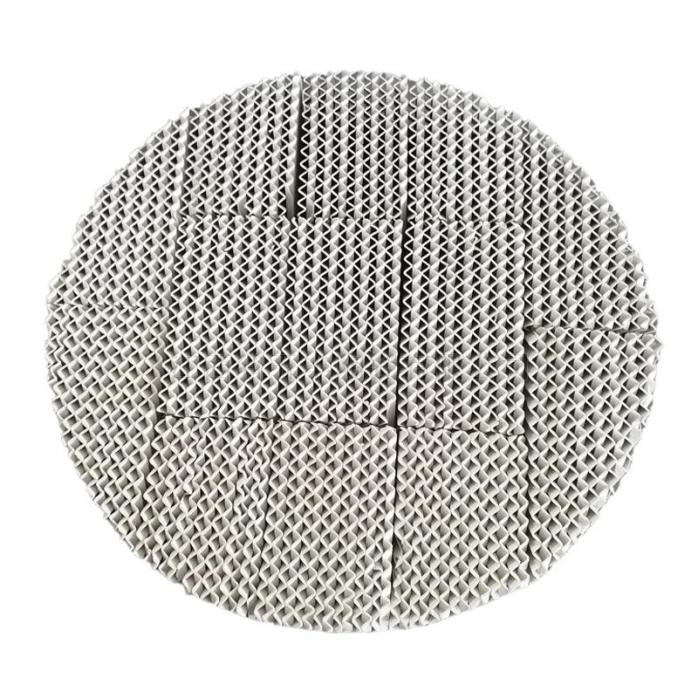

Wear & Heat Resistant Ceramic Structured Packing

Ceramic corrugated packing, as an innovative regular packing material, is composed of numerous uniformly geometrically shaped packing units arranged in an orderly manner. Thanks to the unique structure of the ceramic material, this packing exhibits excellent hydrophilicity. Its surface can form a thin liquid film accompanied by turbulence, while the gas flows in a tortuous channel in an inclined manner, which not only promotes the smooth flow of the gas but also does not hinder its passage. This makes ceramic packing comparable to metal packing in terms of performance, and even has more advantages in terms of corrosion resistance and high-temperature resistance. Moreover, its superior wettability on the surface structure can accelerate the liquid flow, further reducing the liquid retention of the packing, and thereby reducing the risks of overheating, polymerization and coking.

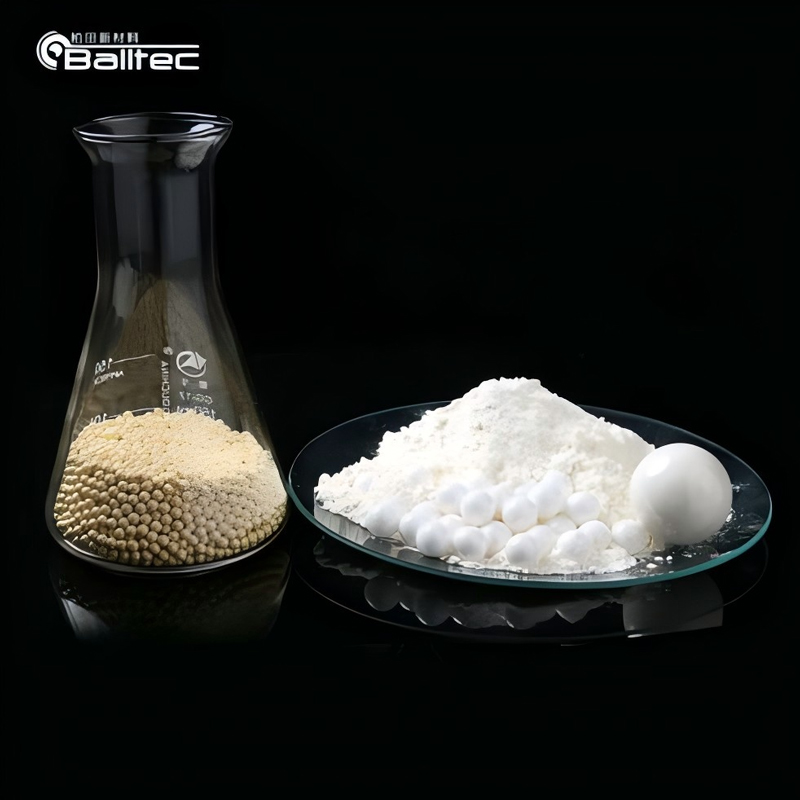

99.9% Al2O3 Grinding Bead Ceramic Grinding Media

Composition

The main component is Al₂O₃, the purity is more than 99.9%, and the impurity content is very low (such as Na, K, Si and other elements are usually in ppm). The purity of some products can reach 99.99%, and the content of radioactive isotopes (such as U and Th) is very low, which is suitable for scenes with strict purity requirements.

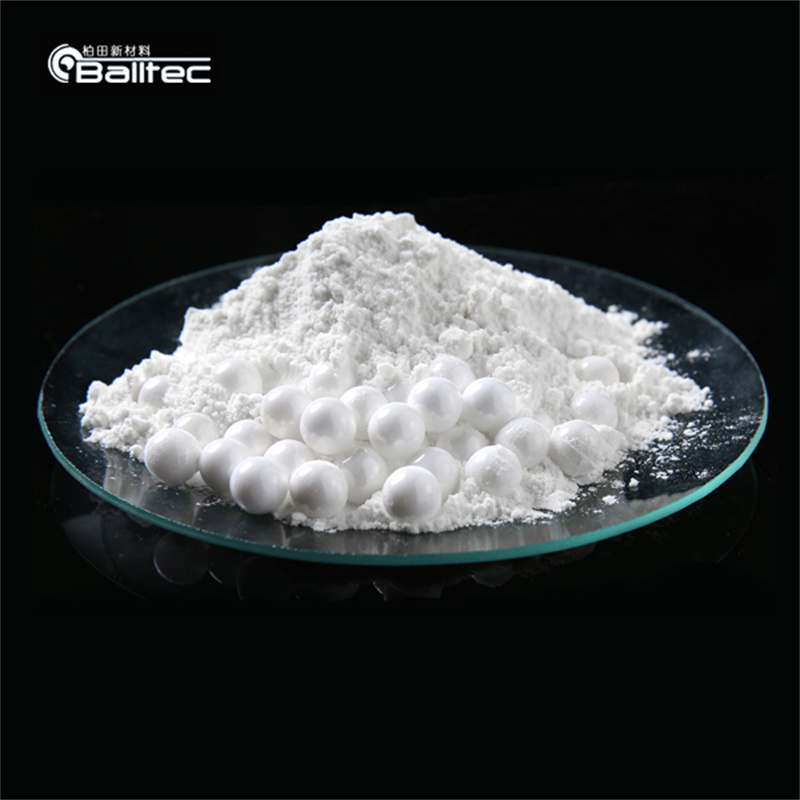

99% High Purity Alumina Al2O3 Grinding Ball Bead

99% purity alumina grinding ball is a kind of high purity, high wear resistance ceramic grinding medium, widely used in chemical, electronics, ceramics and other industries fine grinding and dispersion. The following is its detailed introduction, parameters and uses:

ZrO2 Zirconia Ceramic Ball Beads for Polishing

Zirconium beads can be used to polish many products, polishing zirconium beads generally with 1mm, 2mm, 3mm or more of the beads, can be polished wheels, hardware, medical equipment, jade, rings, necklaces and gold and silver jewelry, in the mirror polishing of the abrasive surface finish requirements are high, abrasive surface to be smooth, can not have grinding force, so that it will not scratch the work. Zirconium beads and polishing liquid are vibrated together in the roller barrel, which can throw the jewelry very bright, eliminating the manual polishing procedure, saving time and effort.

ZrO2 Zirconia Bearing Ball High Precision Ball

The zirconia bearing ball is lighter than the steel ball, reducing the rolling and wear of the channel, the hardness is higher than the steel ball, the surface is smoother than the steel ball, the friction coefficient is smaller, the coefficient of thermal expansion is one quarter of the steel ball, can withstand large temperature changes, the steel ball will rust, but also need to add lubricating oil, but the zirconia ball will not rust, do not need to add lubricating oil when working, So now the slide rail and ceramic bearings are mostly used zirconia balls

Zirconium Oxide Ball for Nano Milling Grinding

Zirconia beads, the color of pearl white, smooth surface, in the ceramic ball is a very hard abrasive, long use time, durable. Zirconia ceramic grinding medium is often used for ultrafine grinding of heavy calcium carbonate, kaolin, mica and other non-metallic minerals.

High Purity 95% Yttria Zirconia Beads

Parameter description

Zirconia content: 95%

Bulk gravity: 3.6g/cm3

Density: 6.1g/cm3

Vickers Hardness: 1250

Color: Pure white

Surface: bright

Size: 0.05mm, 0.1mm, 0.2mm-20mm

Ceria Stabilized Zirconia Bead Zirconia Sintering Beads

Cerium stabilized zirconia beads referred to as cerium zirconia beads, generally yellow, brown, black, relatively high density, widely used for grinding high viscosity materials, such as paint, ink, coatings, adhesives, paper, metal, non-metallic minerals and rare earth materials grinding and dispersion.

Magnesia Stabilizer Zirconia Powder

ZO-P-Mg

General Character

Divide into Magnesia stabilizer zirconia powder Airflow powder and Spray Granulation Powder

Light yellow powder and White powder

Double plastic film sealed plastic bucket:25kg/drum.

impurities controlled at PPM level, super fine and narrow particle size distribution and consistent specific surface area, products processed with this series of powders have characteristic of low sintering temperature, beautiful appearance, high strength, high toughness, good anti-aging properties, no pinhole and easily to process machining etc.

ZTA Zirconia Toughening Alumina Powder

ZO-P-AL

General Character

Various Types: Divide by zirconia content(15%、20%、30%、70%)

White powder

With typical advantages of low sintering temperature and uniform dispersion of two components; product processed with this powders have the characteristics of easily machining properties after firing, high strength, high toughness, high wear resistance, good corrosion resistance and high temperature stability.

Nanometer Zirconia Powder/ Monoclinic Zirconium Oxide Powder /ZrO₂

ZO-P-0Y

Zirconium oxide Series (ZrO₂)

General Character

White powder

Physical properties: insoluble in water, nontoxic, tasteless.

Zirconium dioxide, with the chemical formula ZrO2, is the main oxide of zirconium. It is usually a white, odorless and tasteless crystal that is insoluble in water, hydrochloric acid and dilute sulfuric acid.

Application areas

1. Raw materials for metallic zirconium and its compounds

2. Refractory materials

3. Ceramic materials

3mol%-8mol% Yttria Stabilizer Zirconia Powder/Zirconium Oxide Powder/Y-TZP

ZO-P-Y Series

General Character

3mol%-8mol% Yttria stabilizer zirconia powder, Various type with different binder and lubricating. Granulation spray powder, white powder and airflow powder. Good sphere and Smooth surface. Excellent toughness ,Impact resistence. Very low wear(PPM Level), extremely high hardness and extremely high density.

With advantages of impurities controlled at PPM level, small and narrow particle size distribution and consistent specific surface area, products processed with this series of powders have characteristic of low sintering temperature, beautiful appearance, high strength, high toughness, good anti-aging properties, no pinhole and easily to process machining etc.