Zirconia Grinding Beads Service Life

The Lifespan code of Zirconia Ball grinding beads: A Comprehensive Analysis from Production to Application

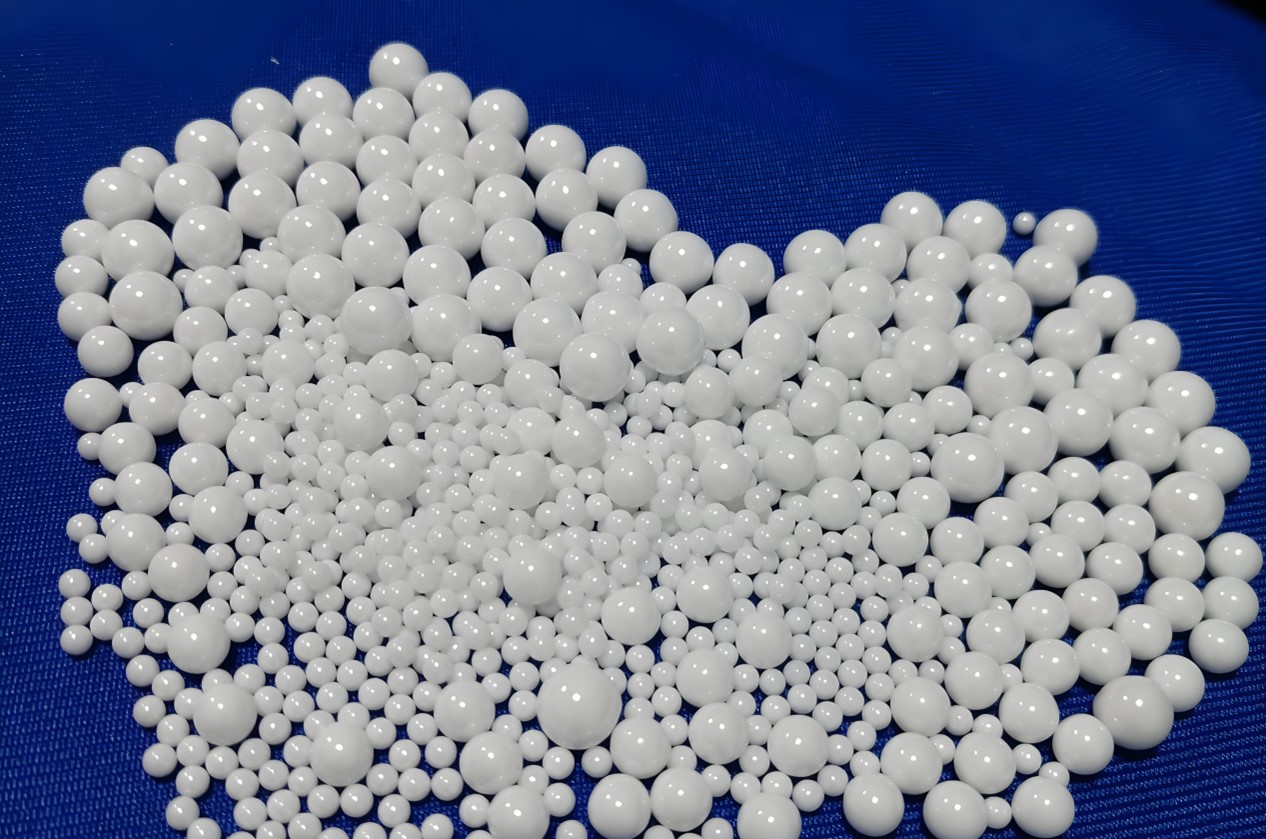

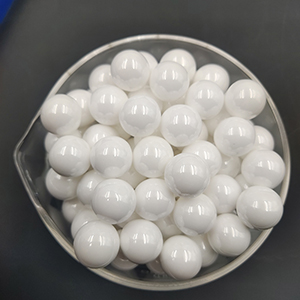

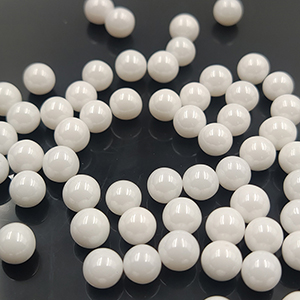

In numerous fields such as chemical engineering, electronics, and new energy, zirconia balls and grinding beads have become key tools in material processing due to their outstanding grinding performance. However, their service lives vary greatly. Some can serve stably for several years, while others are retired prematurely. An in-depth exploration of the influencing factors of the service life of zirconia balls and grinding beads is conducive to reducing costs and increasing efficiency for enterprises and improving production quality.

Innate genes: The production process determines the basic lifespan

The "lifeline" of raw material purity and proportion

The purity of the raw materials of zirconia ball grinding beads directly affects their basic performance. High-purity zirconia raw materials can reduce the damage of impurities to the structure and lower internal defects. Take yttrium-stabilized zirconia grinding beads as an example. The precise proportion of yttrium can optimize the crystal structure and enhance wear resistance and toughness. If the impurity content in the raw materials exceeds the standard, stress concentration points are likely to form at the impurity sites during the grinding process, accelerating the wear and damage of the grinding beads and significantly shortening their service life.

The "shaping magic" of forming and sintering

The forming process is like giving the grinding beads an initial "skeleton". Different processes such as isostatic pressing and injection molding will cause differences in the internal density and stress distribution of the grinding beads. Grinding beads with high density and uniform stress can better resist external impact during grinding. The sintering process can be regarded as a "second transformation". By precisely controlling the sintering temperature and time, the grains of the grinding beads can grow uniformly and the structure can be more stable. If the temperature is too high, the grains will grow abnormally; if it is too low, the bonding will not be tight. Both will weaken the performance of the grinding beads and shorten their service life.

Postnatal Battlefield: The Lifespan "Test" of the Usage Environment

"Strength test" of grinding conditions

In practical use, the working condition parameters of grinding equipment such as rotational speed, grinding time and material filling rate are like a series of "strength tests". If the rotational speed of the equipment is too high, the collisions between the grinding beads and with the materials and the inner walls of the equipment will intensify, and the wear rate will increase significantly. Long-term continuous grinding causes the grinding beads to constantly bear fatigue stress, which makes them prone to cracking and expansion. For instance, in the grinding of cathode materials for lithium batteries, if the material filling rate is too high, the load on the grinding beads will increase, the wear will accelerate, and the service life can be shortened by more than 30%.

The "fatal challenge" of material properties

The hardness, particle size, corrosiveness and other characteristics of the material being ground pose a huge challenge to zirconia balls and grinding beads. When grinding high-hardness materials such as quartz sand, the surface of the grinding beads is constantly subjected to high-intensity impact and scraping, resulting in severe wear. Large particle size of the material will increase the crushing pressure of the grinding beads. Corrosive materials can erode the surface of grinding beads and damage their structure. The requirements for the service life of grinding beads vary across different industries. In the coating industry, due to the relatively mild nature of the materials, the service life of grinding beads is longer. In mining grinding, grinding beads may need to be replaced within just a few months.

The way of Maintenance: The "Secret" to Prolonging life

The "life-prolonging remedy" maintained by science

Regularly clean the grinding equipment to prevent the accumulation of material residues and avoid causing additional wear and corrosion to the grinding beads. Replace severely worn equipment parts, such as grinding discs and linings, in a timely manner to reduce abnormal wear of grinding beads caused by equipment problems. At the same time, controlling the temperature and humidity of the grinding environment to prevent the grinding beads from undergoing phase transformation or performance deterioration due to environmental changes is crucial for extending the service life of the grinding beads.

The "key decision" for reasonable selection

According to specific grinding requirements, select zirconia ball grinding beads of appropriate specifications and performance. For fine grinding, small-sized and high-toughness grinding beads are selected. For coarse grinding, large-sized and high-hardness grinding beads can be used. Matching different production scenarios and precise selection can fully leverage the performance advantages of grinding beads and effectively extend their service life.

The service life of zirconia ball grinding beads is jointly influenced by multiple factors such as production process, usage environment and maintenance. From raw material control to scientific use and maintenance, every link is related to the "lifespan" of the grinding beads. Only by thoroughly understanding these influencing factors and taking targeted measures can enterprises maximize the value of zirconia balls and grinding beads, reduce production costs and enhance production efficiency.

This article conducts a detailed analysis of the influencing factors on the service life of zirconia ball grinding beads. If you think some parts need to be supplemented with cases or there are other directions for modification, please feel free to tell me.