Will zirconia ball break?

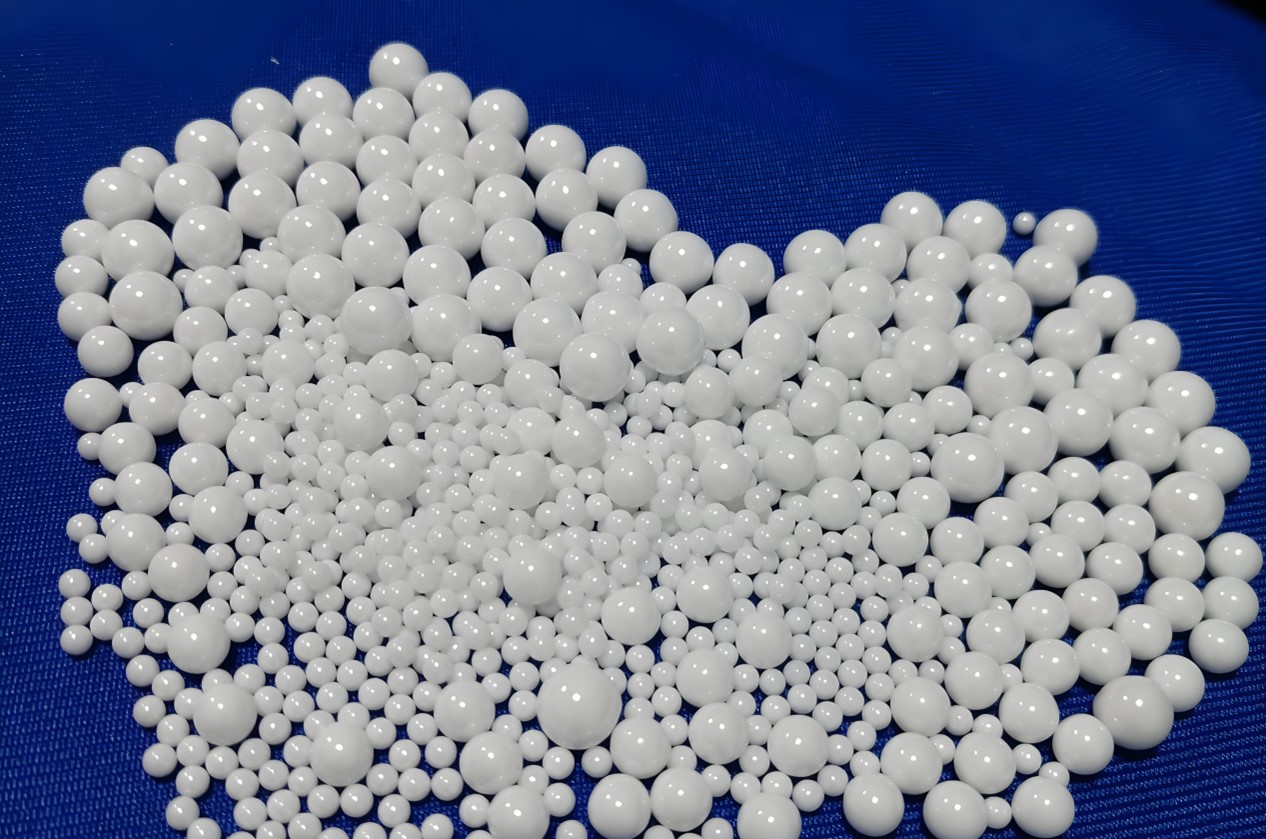

Zirconium Balls in the production process, if the production process is not well controlled, there will be bubble balls, snowman balls, tail balls, flat balls, these balls in the sand mill is easy to break, so we use zirconium balls can not be cheap, different manufacturers have different production processes, the simplest way is to take a hammer first, it is easy to smash the balls is certainly not good quality

Zirconia Ball will be broken under specific conditions, whether it is broken mainly depends on the quality of balls, equipment parameters, grinding material properties and other factors. Here's a breakdown:

First, the common causes of breakage

ball quality problem

Production process defects (such as bubble balls, snowman balls, tail balls, flat balls, etc.) can cause stress concentration and be easily broken during grinding.

Low purity or poor quality stabilizers (such as magnesium/calcium stabilizers) can reduce strength and increase the risk of breakage.

Device parameters do not match

High energy equipment: such as Swiss Dyno-mill ECM horizontal sand mill, German Drais DCP vertical sand mill, etc., the input energy density is high, and pure zirconium balls (95% ZrO₂) need to be used to avoid crushing.

Line speed is too high: the speed of the sander is too fast, which will cause the collision between the balls and the dispersion disk, the screen and other components to intensify.

Abnormal back pressure: Residual pressure may crush accumulated balls when the pump is turned off.

Properties of grinding materials

Materials that are harder than the ball (such as aluminum, diamond, glass powder) can cause the ball to be worn or broken.

When cleaning with high viscosity liquids, balls may break upon contact with the dispersion tray.

2. Judgment of normal wear and abnormal breakage

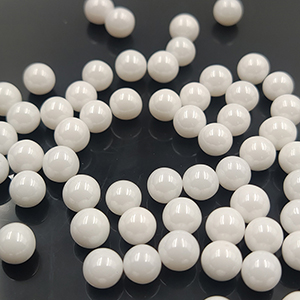

Normal wear: The size of the ball is reduced, the surface is smooth without edges and corners, which belongs to the wear process.

Abnormal breakage: the appearance of angular, flake or shaped balls, indicating that quality problems or equipment problems lead to fragmentation.

Third, measures to prevent breakage

Choose quality balls

Yttrium stabilized type (95% ZrO₂) or cerium stabilized type (80% ZrO₂) are preferred to avoid defective products such as bubble balls and snowman balls.

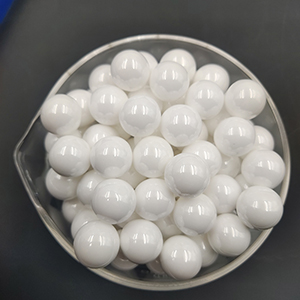

ball stability was verified by 24 hours self-wear test.

Optimize equipment parameters

High energy equipment to use pure zirconium balls, and control the speed of the sand mill and line speed.

Regularly check the dispersion plate, screen and other components to avoid wear or loose resulting in broken balls.

Standardize operation and maintenance

Avoid high-speed idling or frequent start and stop to prevent ball impact.

Use a low viscosity liquid when cleaning and shorten the cleaning time to reduce ball contact risk.

Check the ball wear regularly, and replace it in time when the broken ball rate exceeds 10%.

Iv. Summary

Zirconia Balls in normal grinding will gradually become smaller due to wear, but if there is abnormal breakage (such as corners, sheets), you need to check the quality of balls, equipment parameters, material matching and other problems. By selecting high-quality products, optimizing equipment Settings and standardizing operations, the risk of breakage can be significantly reduced.