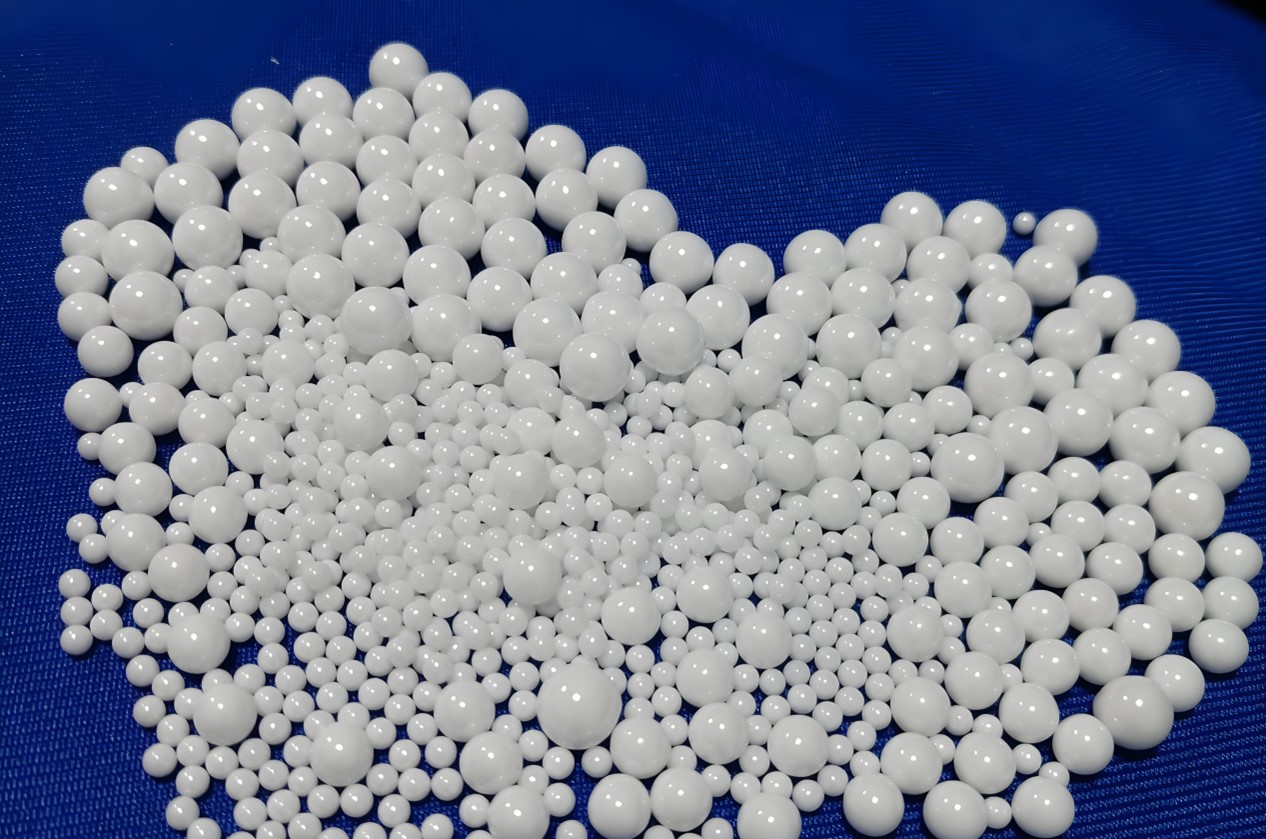

The use of zirconia balls

Because of its excellent physical and chemical properties, Zirconia Balls are widely used in many fields, the following are its main uses:

Grinding and dispersing media

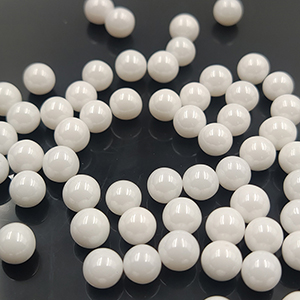

Zirconia ball hardness, good wear resistance, often used in non-metallic ore, paint, ink, dyes, titanium dioxide and other industries of ultrafine grinding and dispersion, can improve grinding efficiency and reduce wear. It is also used as a polishing medium in high-precision machining of electronic components and ceramic materials.

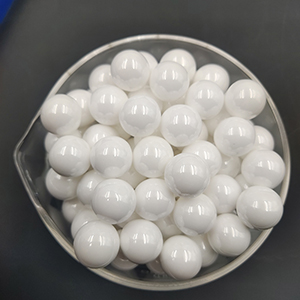

Industrial structural parts

As a component material such as bearings and seals, zirconia balls have high temperature resistance, corrosion resistance, electrical insulation and other characteristics, suitable for extreme working conditions. For example, all-ceramic bearings can be used for micro-cooling fans, with better life and stability than traditional metal bearings.

Catalyst support

Its high specific surface area and chemical stability make it an ideal carrier for catalytic reactions such as petroleum processing and chemical synthesis, especially in the fields of nitrogen dioxide reduction and methane catalysis.

Biomedical field

Due to their excellent biocompatibility and mechanical strength, zirconia balls are used to manufacture medical devices such as artificial joints, dental implants, and surgical knives, which can extend their service life and reduce human rejection.

Electronic and Functional Ceramics

As the raw material of capacitors, piezoelectric ceramics and other electronic components, zirconia balls play an important role in sensors, filters and other circuits. In addition, high temperature heating elements and oxygen sensors also depend on their characteristics.

Other applications

These include additives in steel production (to improve the hardness and toughness of steel), high-temperature kiln parts, aerospace coating materials, etc. Its low wear characteristics can also be used in precision abrasive manufacturing.

The preparation methods of zirconia balls are various (such as sol-gel method, high temperature melting method), and the particle size and purity can be controlled to meet different high-end needs. With the advancement of technology, its application scenarios will be further expanded.