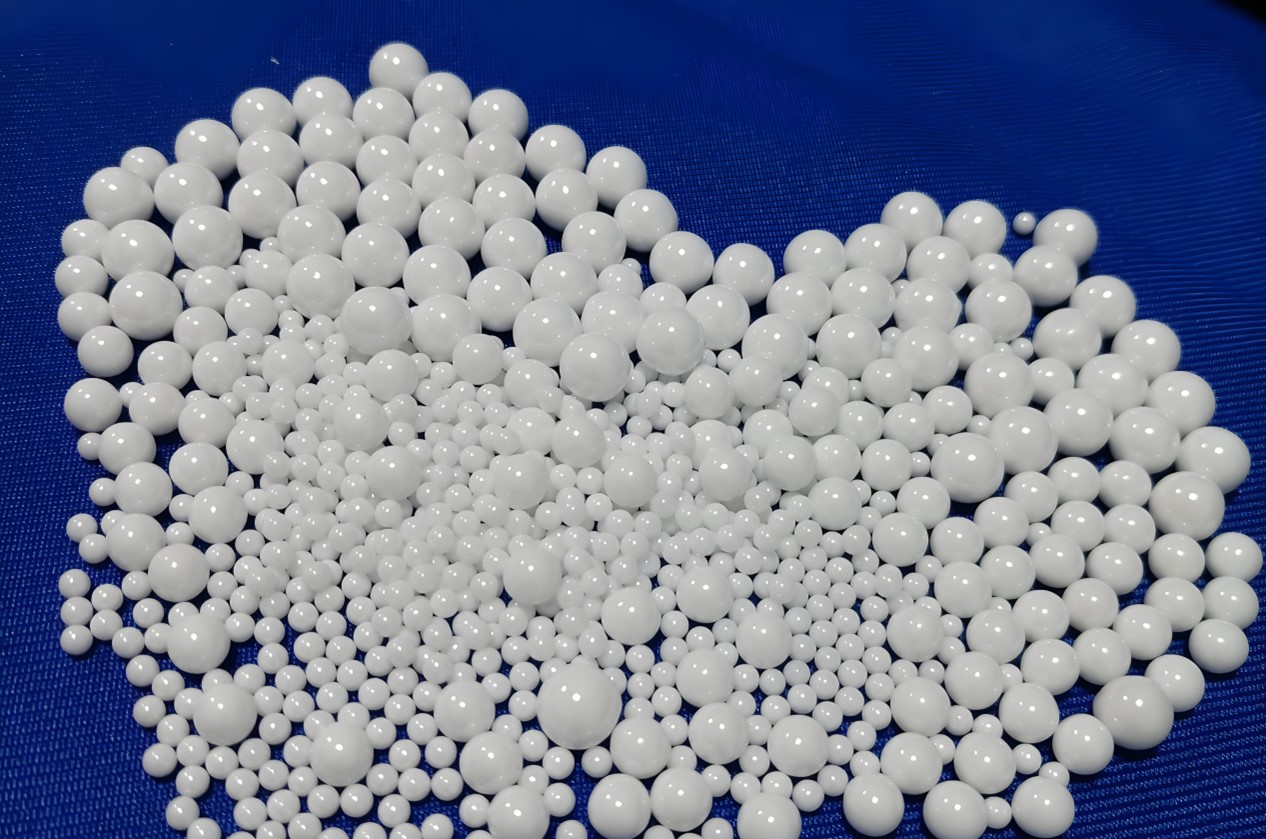

The hardness test method of zirconium ball

Zirconium Ball hardness testing methods need to be selected according to material characteristics and testing needs, the following are the main testing methods and basis:

First, commonly used hardness testing methods

Vickers Hardness Test (HV)

The hardness value is calculated by applying a constant load to the diamond indenter and measuring the diagonal length of the indentation. Suitable for high hardness materials (such as Zirconia Balls), in line with the industry standard GB/T1946 for pure zirconium balls hardness ≥ Mohs level 7 requirements. Zirconia balls (such as yttrium stabilized ones) have a Vickers hardness of 12-14 gpa (Yomos class 9).

Mohs hardness test

Using the carving method to divide the hardness level (1-10), the Mohs hardness of zirconia ball is 7-8.5, which is close to sapphire. However, the accuracy of this method is low, and it is mostly used for preliminary evaluation or non-precision scenes.

Rockwell Hardness Test (HRC/HRA)

By diamond indenter or steel ball pressed into the material surface, suitable for extremely hard materials. Zirconium ball due to high wear resistance, some scenarios may use Rockwell hardness supplement verification.

2. Testing standards and precautions

Industry standard

Pure zirconium balls must meet GB/T1946 standards, hardness ≥ Mohs level 7.

Zirconia balls (such as 95% ZrO₂) have a Mohs hardness of 7-8.5 and need to be combined with the sintering process (1400-1600 ° C) to ensure densification.

Test gist

Sample preparation: It is necessary to ensure that the surface is smooth and without cracks to avoid test errors.

Environmental control: High temperature or acid-alkali environment may affect the hardness value, and it needs to be operated under standard conditions.

Instrument calibration: Calibrate the hardness tester regularly to ensure data accuracy.

3. Suggestions on application scenarios

Industrial grinding: Vickers hardness test is preferred, combined with Rockwell hardness to verify wear resistance.

Quality control: According to GB/T1946 standard, sample testing of batch products.

Scientific research: It can compare Mohs, Vickers and other methods to analyze the influence of material microstructure on hardness.

In summary, the core method of zirconium ball hardness testing is Vickers hardness, supplemented by the preliminary evaluation of Mohs hardness, which needs to strictly follow the standards and control the test conditions.