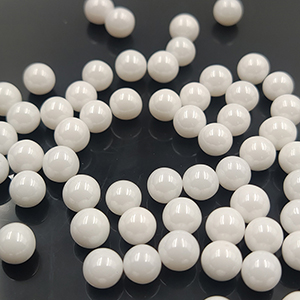

The Advantages of Zro2 Balls: Revolutionizing Grinding and Milling Applications

In the realm of industrial grinding and milling, Zro2 Balls have emerged as a game - changing component, offering a plethora of advantages that set them apart from traditional grinding media. These beads, composed primarily of zirconium dioxide (ZrO2), have found widespread use across various industries, from ceramics and electronics to pharmaceuticals and paints.

1. Exceptional Hardness and Wear Resistance

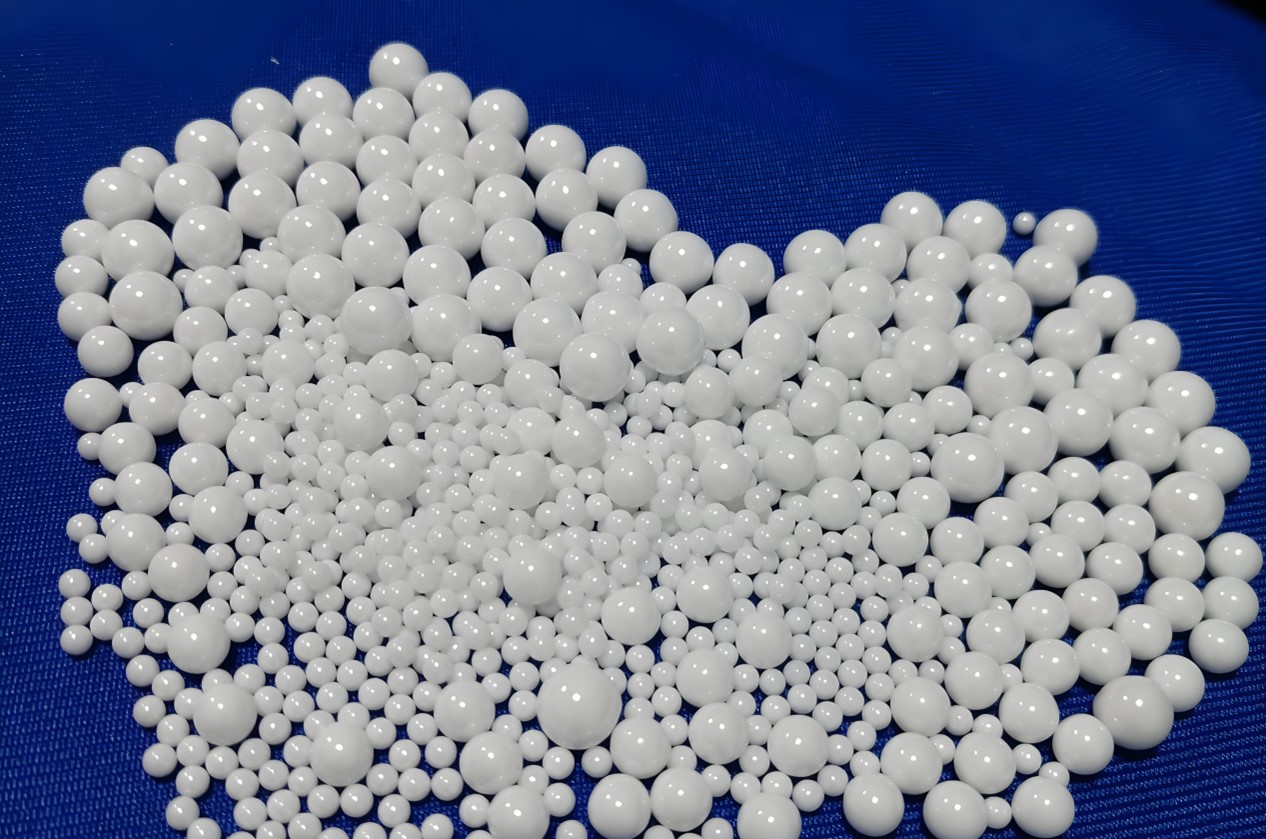

One of the most prominent advantages of zro2 balls is their remarkable hardness. On the Mohs hardness scale, they typically range from 8 to 9, making them highly resistant to abrasion. This inherent hardness allows them to maintain their spherical shape and size even after prolonged use in aggressive grinding environments.

In contrast to other grinding media like glass beads or steel balls, zro2 balls exhibit minimal wear over time. For instance, in the production of ceramic slurries, where the grinding process can be particularly harsh, zro2 balls can endure thousands of grinding cycles without significant degradation. This not only ensures consistent grinding performance but also reduces the frequency of media replacement, leading to cost savings in the long run.

2. High Density for Efficient Grinding

zro2 balls possess a relatively high density, usually in the range of 6.0 - 6.5 g/cm³. This high density translates to a greater impact force during the grinding process. When used in a mill, the beads can more effectively transfer energy to the material being ground, resulting in faster and more efficient particle size reduction.

In applications such as the dispersion of pigments in paint production, the high - density zro2 balls can break down agglomerated pigment particles more quickly. This leads to improved color uniformity and stability of the paint, as well as a reduction in the overall grinding time, thereby increasing production efficiency.

3. Chemical Inertness and Purity

Zirconia is a chemically inert material, which means it has excellent resistance to chemical reactions with most substances. This property is of utmost importance in industries where the purity of the final product is critical, such as in the pharmaceutical and food sectors.

For example, in the manufacturing of pharmaceutical powders, zro2 balls can be used to grind active pharmaceutical ingredients without the risk of contaminating the product. Their chemical inertness ensures that no unwanted reactions occur, preserving the efficacy and safety of the pharmaceutical formulations. Additionally, zro2 balls are often produced with high purity, further minimizing the potential for introducing impurities into the grinding process.

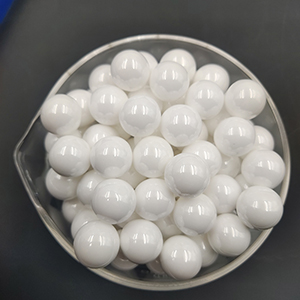

4. Low Agglomeration and Good Dispersion

zro2 balls have a smooth surface and low surface energy, which contributes to their low agglomeration tendency. This means that they are less likely to stick together or form clusters during the grinding process, ensuring a more uniform distribution of the beads within the mill.

In the production of nanomaterials, where achieving a narrow particle size distribution is crucial, the good dispersion of zro2 balls is highly beneficial. They can effectively disperse and grind nanoscale particles without causing excessive agglomeration, resulting in nanomaterials with consistent properties. This advantage also extends to other applications such as the production of advanced ceramics and electronic materials.

5. Thermal Stability

zro2 balls exhibit good thermal stability over a wide range of temperatures. They can withstand both high - temperature and low - temperature environments without significant changes in their physical or chemical properties.

In processes where temperature variations are common, such as in some industrial drying and calcination operations that are preceded or followed by grinding, zro2 balls can maintain their performance. For example, in the production of ceramic coatings, where the grinding of ceramic powders may be followed by a high - temperature curing process, zro2 balls do not degrade due to the subsequent temperature increase, ensuring the quality of the final coating.

In conclusion, zro2 balls offer a unique combination of hardness, density, chemical inertness, dispersion characteristics, and thermal stability. These advantages make them an ideal choice for a wide variety of grinding and milling applications, enabling industries to achieve higher product quality, increased production efficiency, and reduced costs. As technology continues to advance, it is likely that the use of zro2 balls will become even more prevalent across different sectors, further solidifying their position as a key component in modern industrial processing.