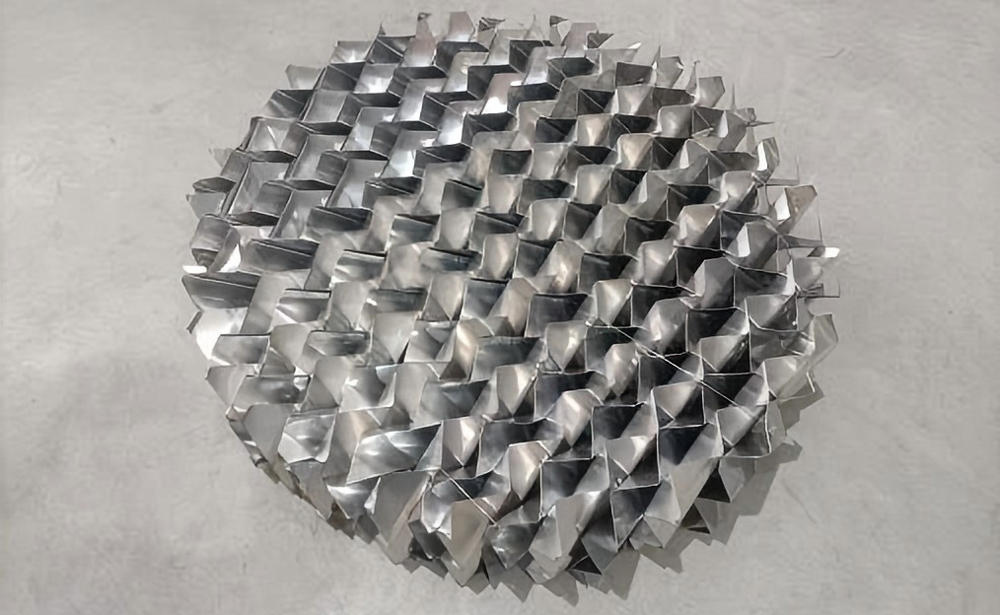

The Advantages And Disadvantages Of Structured Packing

Advantages:

high mass transfer efficiency: the surface of regular packing has regular morphology and geometric characteristics, large surface area and high porosity, which can provide a large mass transfer interface. When the fluid passes through the packing layer, the friction loss is reduced and the mass transfer efficiency is improved.

one

pressure reduction: The Structured Packing has an open structure, high porosity, large voidage, and small resistance to fluid passing through the packing layer, so the pressure drop is relatively low, saving energy.

excellent corrosion resistance: structured fillers are usually made of corrosion-resistant materials. For highly corrosive liquids or gases, structured fillers have stronger corrosion resistance than traditional fillers.

high mechanical strength: regular packing structure is tight, usually made of high temperature, high pressure and bending resistant materials, not easy to break and damage.

uniform fluid distribution: The structure of regular packing makes the fluid distribution in the tower more uniform, improve the efficiency of mass and heat transfer.

Disadvantages:

higher cost: structured fillers are usually made of high-performance materials, higher manufacturing costs, and higher prices than traditional fillers.

difficult operation: regular packing needs to strictly follow the installation requirements during the use of high requirements for the operator, improper operation may affect the effect of use.

Limited scope of application: Although structured fillers are suitable for a variety of chemical processes, in some specific application scenarios, their performance may not be as good as other types of fillers.

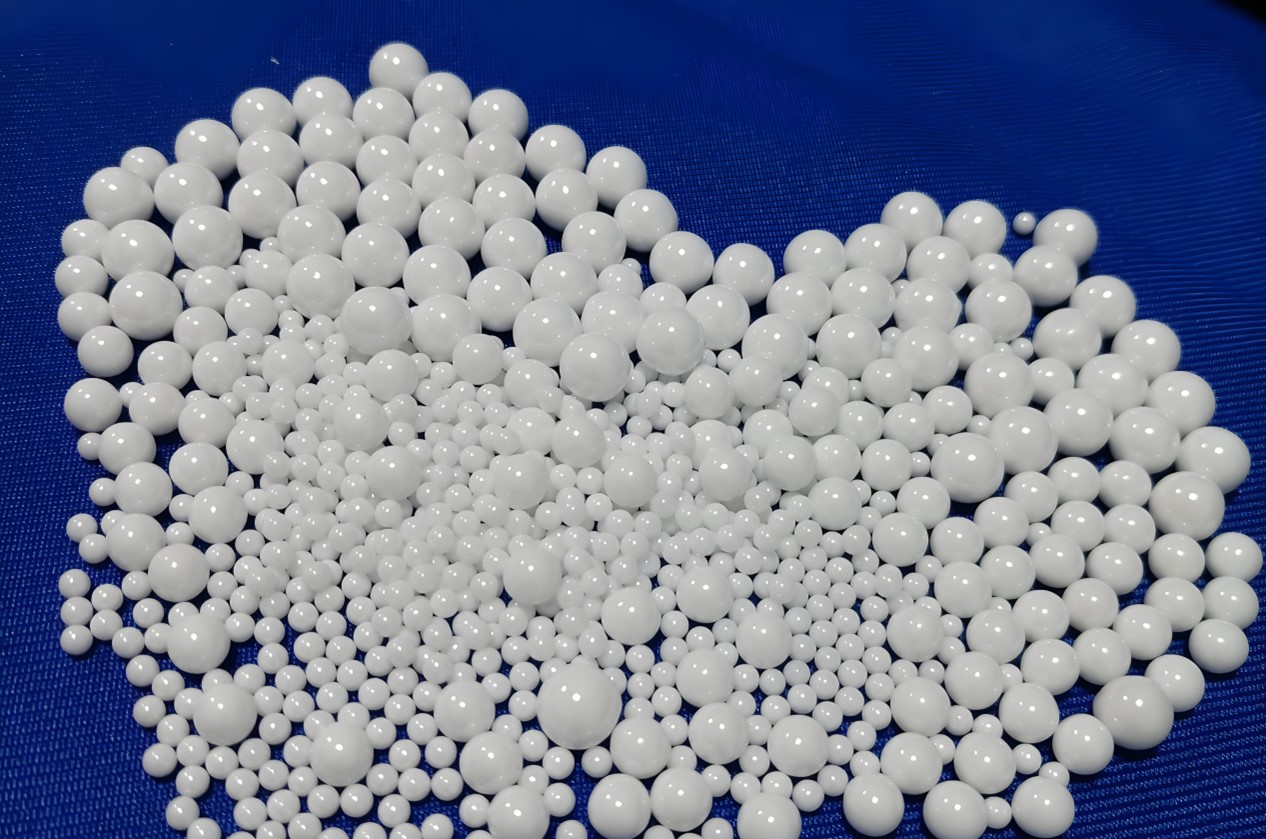

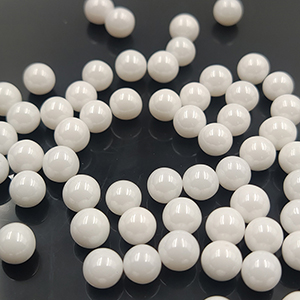

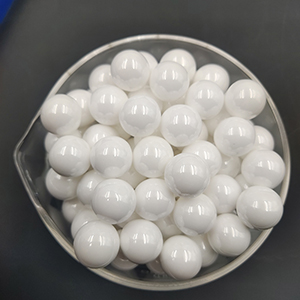

Advantages and disadvantages of bulk fillers

Advantages:

high efficiency: high efficiency of bulk packing, small pressure drop, large processing capacity, uniform distribution of gas and liquid, small liquid holdup, not obvious amplification effect, large flexibility of operation.

low cost : The cost of bulk fillers is relatively low, suitable for large-scale applications.

operation flexibility : the operation flexibility of bulk packing is large, strong adaptability.

Disadvantages :

cleaning difficulty : bulk packing cleaning is more difficult, not easy to clean thoroughly, there may be residue.

easy blockage : after use for a period of time, the bulk filler is easy to deposit sulfur paste and dirt, resulting in gas-liquid bias, forming a dry area, affecting the normal operation of the system.