Reasons for Zirconia Ball Cracking

Why are Zirconia Balls "scarred all over"? In-depth analysis of the causes of cracking

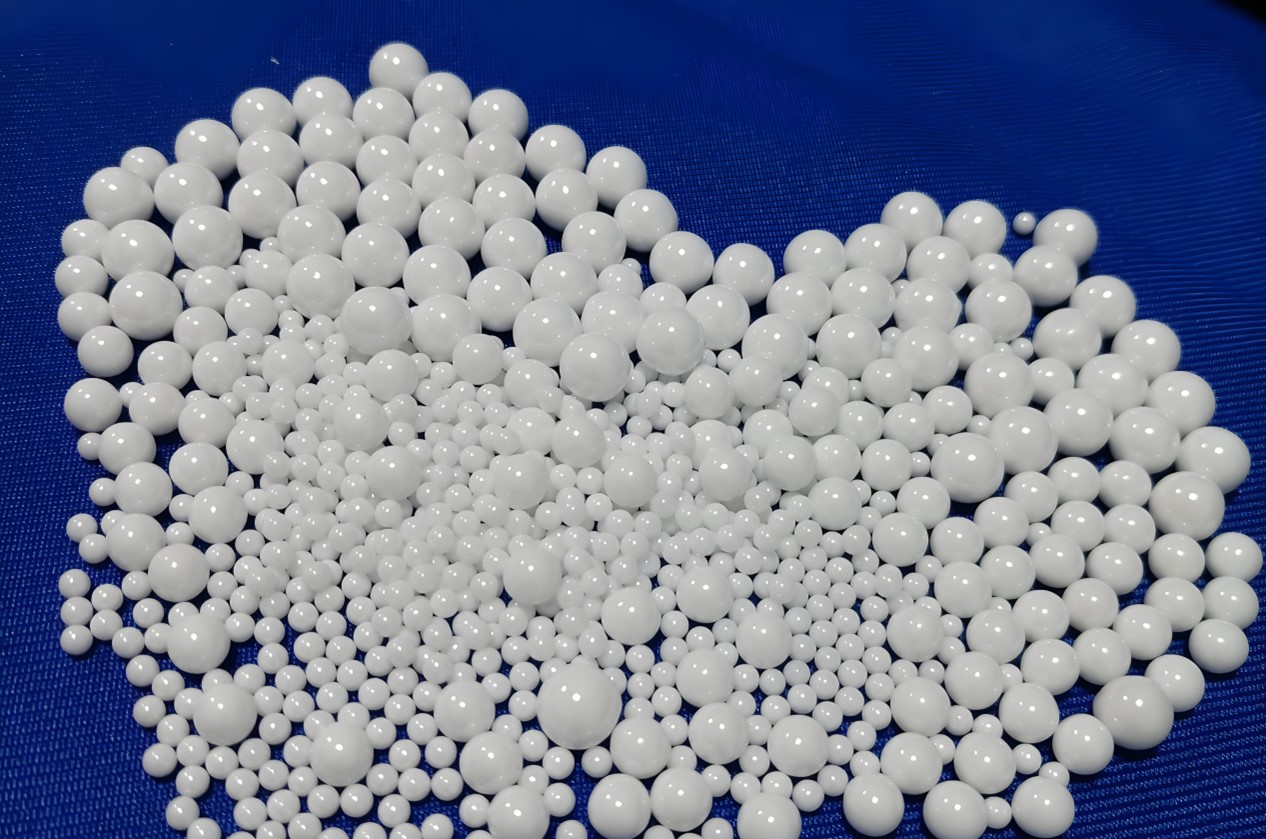

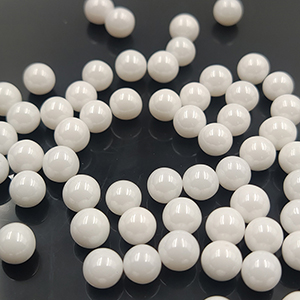

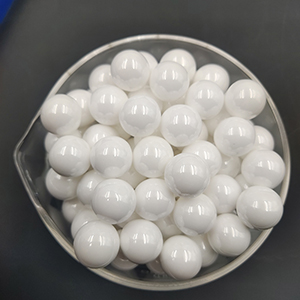

In the field of material processing and grinding, zirconia balls have become the "capable assistants" of many industries due to their outstanding performance. However, cracking of zirconia balls occurs from time to time during use, which not only affects production efficiency but also increases costs. Only by thoroughly exploring the causes of zirconia ball cracking can we prescribe the right medicine and solve the problem.

The "inherent deficiencies" in the production and manufacturing process

The quality of raw materials varies greatly

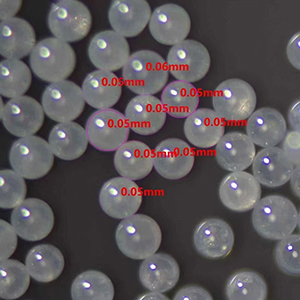

The production of zirconia balls is crucial for the purity and particle size of raw materials. If the impurity content in the zirconia raw material is too high, such as containing a large amount of iron, calcium and other impurities, during the high-temperature sintering process, the impurities will react with the zirconia, change its internal structure, reduce the strength of the sphere, and thus lay the hidden danger of cracking. Meanwhile, uneven particle size distribution of raw materials will also lead to inconsistent internal density and uneven stress distribution of the spheres during molding and sintering, eventually causing cracking. For instance, due to excessive particle size differences in a certain batch of raw materials, the zirconia balls made from them developed a large number of cracks in the initial stage of use.

Improper forming process

The forming methods of zirconia balls are diverse, such as isostatic pressing and injection molding. Each forming process has its specific requirements. If not operated properly, it is very likely to cause cracking. Take isostatic pressing as an example. If the pressure is applied unevenly, it will cause local stress concentration inside the sphere. The holding time was insufficient, and the material was not fully compacted, resulting in voids inside the spheres. During the subsequent sintering and usage processes, cracks are prone to occur around these voids.

The sintering process is out of control.

Sintering is a key link that determines the performance of zirconia balls. If the sintering temperature is too high, it will cause abnormal growth of zirconia grains, resulting in a loose internal structure of the sphere, a decrease in strength, and eventually cracking. If the sintering temperature is too low, the particles inside the sphere cannot be fully fused, and the bonding strength is insufficient, which is also prone to cracking. In addition, unreasonable control of the heating and cooling rates will cause excessive thermal stress inside the sphere, which is also an important cause of cracking. For instance, rapid heating may lead to an excessive temperature difference between the surface and the interior of the sphere, generating thermal stress and eventually causing surface cracking.

"Acquired damage" during use

The operation parameters are unreasonable

In grinding equipment, operating parameters such as rotational speed and grinding time have a significant impact on zirconia balls. If the rotational speed of the equipment is too high, the movement speed of the zirconia balls will increase, and the impact force between them, as well as with the materials and the inner walls of the equipment, will increase. If the impact force exceeds the ball's tolerance range, it will lead to cracking. If the grinding time is too long, the zirconia balls will be continuously subjected to wear and stress, and fatigue cracks will gradually appear, eventually developing into cracking. For instance, in a sand mill, if it operates at an excessively high speed for a long time, the cracking rate of zirconia balls will increase significantly.

The material properties do not match the grinding method

The hardness, particle size and other characteristics of different materials vary greatly. When grinding materials with high hardness or large particle size, if the selected zirconia balls have insufficient strength, they are prone to cracking due to the impact of the materials during the grinding process. In addition, improper grinding methods, such as an inappropriate ratio of grinding medium to material, and excessive material will increase the load on zirconia balls, making them more prone to damage and subsequently causing cracking.

The influence of environmental factors

Drastic changes in environmental temperature and humidity may also cause cracking of zirconia balls. In cold environments, the toughness of zirconia balls decreases and they become more brittle and hard. At this time, if they are impacted by external forces, they are more likely to crack. In an environment with high humidity, zirconia balls may undergo phase transformation due to moisture absorption, resulting in volume changes, an increase in internal stress, and eventually causing cracking.

The cracking of zirconia balls is caused by the combined effect of multiple factors during the production, manufacturing and usage processes. From raw material control to the optimization of forming and sintering processes, and then to the reasonable setting of operation parameters during the usage process, matching material characteristics and paying attention to environmental impacts, only by comprehensively inspecting and solving problems can the cracking phenomenon of zirconia balls be effectively reduced and their performance advantages be fully exerted.