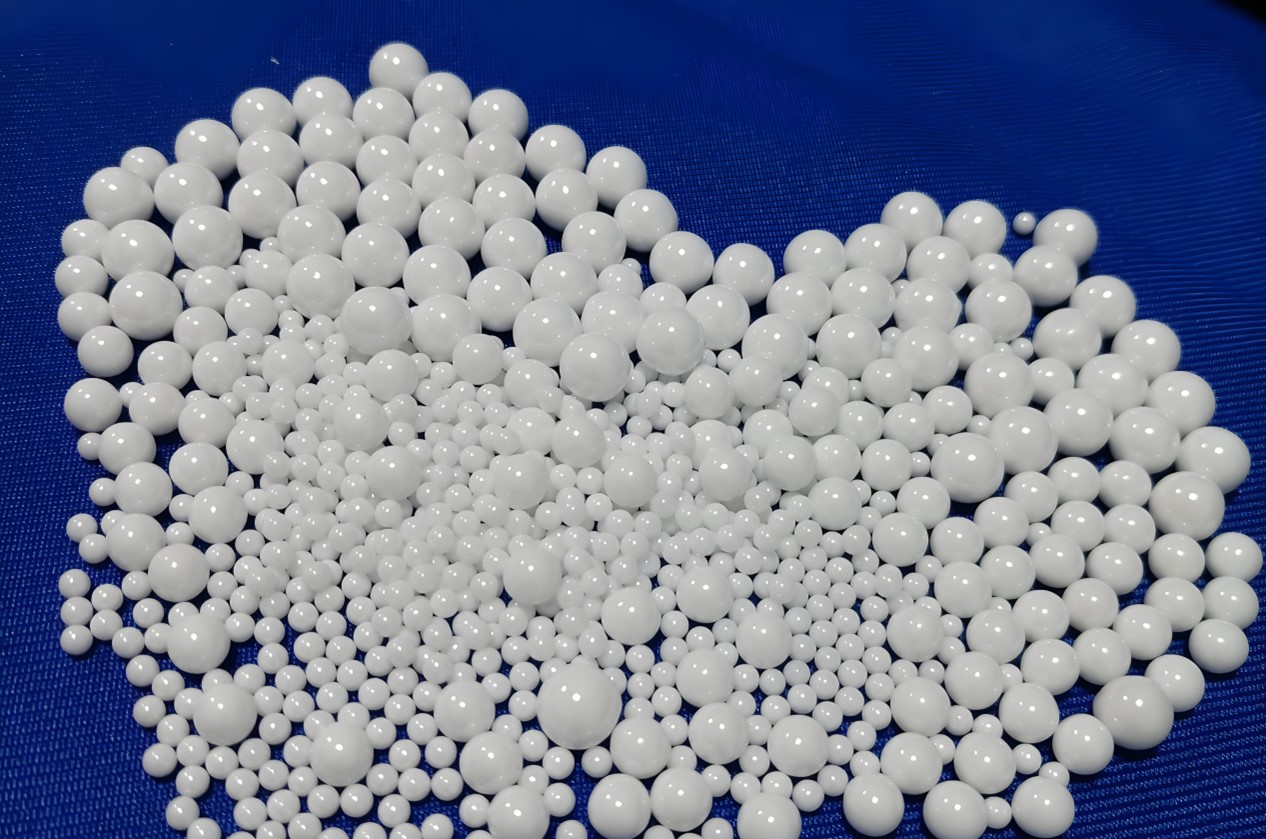

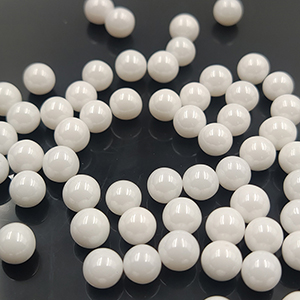

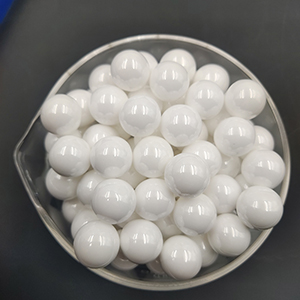

How to Clean Zirconia Beads for Laboratory Use

1. Pre-Cleaning Assessment

Before initiating the cleaning process, it is crucial to assess the nature of the contaminants on the zirconia beads. Common contaminants include:

- Organic residues from biological samples, polymers, or hydrocarbons

- Inorganic salts or metal ions from chemical reactions

- Particulate matter from ground samples

- Microbial growth in biological applications

2. Physical Cleaning Methods

2.1 Initial Rinsing

Start with a gentle rinse using deionized water to remove loose particulate matter. For beads used in non-hazardous applications, place them in a glass beaker and rinse with copious amounts of deionized water, agitating gently to dislodge surface particles. For more tenacious particles, use a syringe or squirt bottle to direct a stream of water over the beads.

2.2 Ultrasonic Cleaning

Ultrasonication is effective for removing adhered particles and films. Prepare a bath of deionized water in an ultrasonic cleaner and immerse the beads. Run the cleaner for 10-15 minutes, ensuring the water temperature does not exceed 50°C to avoid thermal stress. For oily or greasy residues, add a few drops of a non-ionic detergent (e.g., Tween 20) to the water. After ultrasonication, rinse the beads thoroughly with deionized water to remove detergent residues.

3. Chemical Cleaning Protocols

3.1 Removal of Organic Contaminants

3.1.1 Acid Cleaning

For organic residues, a mild acid treatment is often effective. Soak the beads in a 10% nitric acid (HNO₃) solution for 1-2 hours. Nitric acid is preferred for its oxidizing properties and volatility, which facilitates easy rinsing. Alternatively, a 5% hydrochloric acid (HCl) solution can be used for non-sensitive applications. After acid treatment, rinse the beads repeatedly with deionized water until the rinse water reaches a neutral pH (measured with pH paper or meter).

3.1.2 Oxidizing Agents

For stubborn organic contaminants, such as proteins or polymers, an oxidizing agent like 30% hydrogen peroxide (H₂O₂) or a potassium permanganate (KMnO₄) solution can be used. Soak the beads in the oxidizing solution for 30 minutes to 1 hour, followed by thorough rinsing with deionized water. Caution should be exercised with hydrogen peroxide, as it may generate oxygen gas, and proper ventilation is essential.

3.2 Removal of Inorganic Contaminants

3.2.1 Chelating Agents

To remove metal ions or inorganic salts, use a chelating agent such as ethylenediaminetetraacetic acid (EDTA) in a 0.1M solution adjusted to pH 7-8 with sodium hydroxide (NaOH). Soak the beads for 1-2 hours, then rinse extensively with deionized water. EDTA forms stable complexes with metal ions, facilitating their removal.

3.2.2 Alkaline Cleaning

For inorganic residues that are acidic in nature, a 5% sodium hydroxide (NaOH) solution can be used. Soak the beads for 30 minutes, followed by rinsing with deionized water until neutral. Alkaline cleaning is effective for removing silica-based residues or certain metal oxides.

3.3 Microbiological Decontamination

For beads used in biological applications, decontamination to remove microbial pathogens is essential. Soak the beads in a 70% ethanol solution for 30 minutes, or use a 0.1% sodium hypochlorite (bleach) solution for 15-20 minutes. After disinfection, rinse the beads thoroughly with deionized water to remove any residual disinfectant, which could interfere with subsequent experiments.

4. High-Temperature Cleaning (Calcination)

For applications requiring ultra-high purity, such as trace metal analysis, calcination can be used to remove organic contaminants and volatile inorganic substances. Place the cleaned beads in a ceramic crucible and heat them in a muffle furnace at 500-600°C for 2-3 hours. This process decomposes organic matter and drives off volatile residues. Allow the beads to cool slowly in the furnace to prevent thermal shock, which could cause cracking.

5. Post-Cleaning Validation

After cleaning, it is important to verify the effectiveness of the process to ensure no residual contaminants remain. Methods for validation include:

5.1 Visual Inspection

Examine the beads under a microscope to check for any visible residues or discoloration. Clean beads should have a uniform, glossy surface without any spots or films.

5.2 Surface Analysis

For critical applications, use surface analysis techniques such as scanning electron microscopy (SEM) or energy-dispersive X-ray spectroscopy (EDS) to check for elemental impurities.

5.3 Solvent Extraction and Analysis

Rinse the cleaned beads with a suitable solvent (e.g., methanol or acetonitrile) and analyze the extract using techniques like inductively coupled plasma mass spectrometry (ICP-MS) or gas chromatography-mass spectrometry (GC-MS) to detect trace contaminants.

6. Handling and Storage Precautions

- Avoid using metal tools when handling cleaned zirconia beads, as this could introduce metal contaminants. Use plastic or ceramic forceps instead.

- Store cleaned beads in clean, dry glass containers with tight-fitting lids to prevent recontamination. Label the containers with the date of cleaning and the method used.

- Never use hydrofluoric acid (HF) to clean zirconia beads, as it reacts with zirconia (ZrO₂) to form soluble fluorides, damaging the beads.

- For beads used in sensitive applications, perform a blank test with the cleaned beads to ensure they do not introduce artifacts into the experiment.

7. Recycling and Disposal

If zirconia beads are too damaged to be cleaned (e.g., cracked or chipped), they should be disposed of according to local hazardous waste regulations. However, properly cleaned and undamaged beads can be reused multiple times, making them a cost-effective choice for laboratory applications.

By following these professional cleaning procedures, laboratory personnel can ensure that zirconia beads remain free from contamination, maintain their mechanical properties, and provide reliable performance in various experimental setups. Regular and proper cleaning not only extends the lifespan of the beads but also enhances the accuracy and reproducibility of laboratory results.