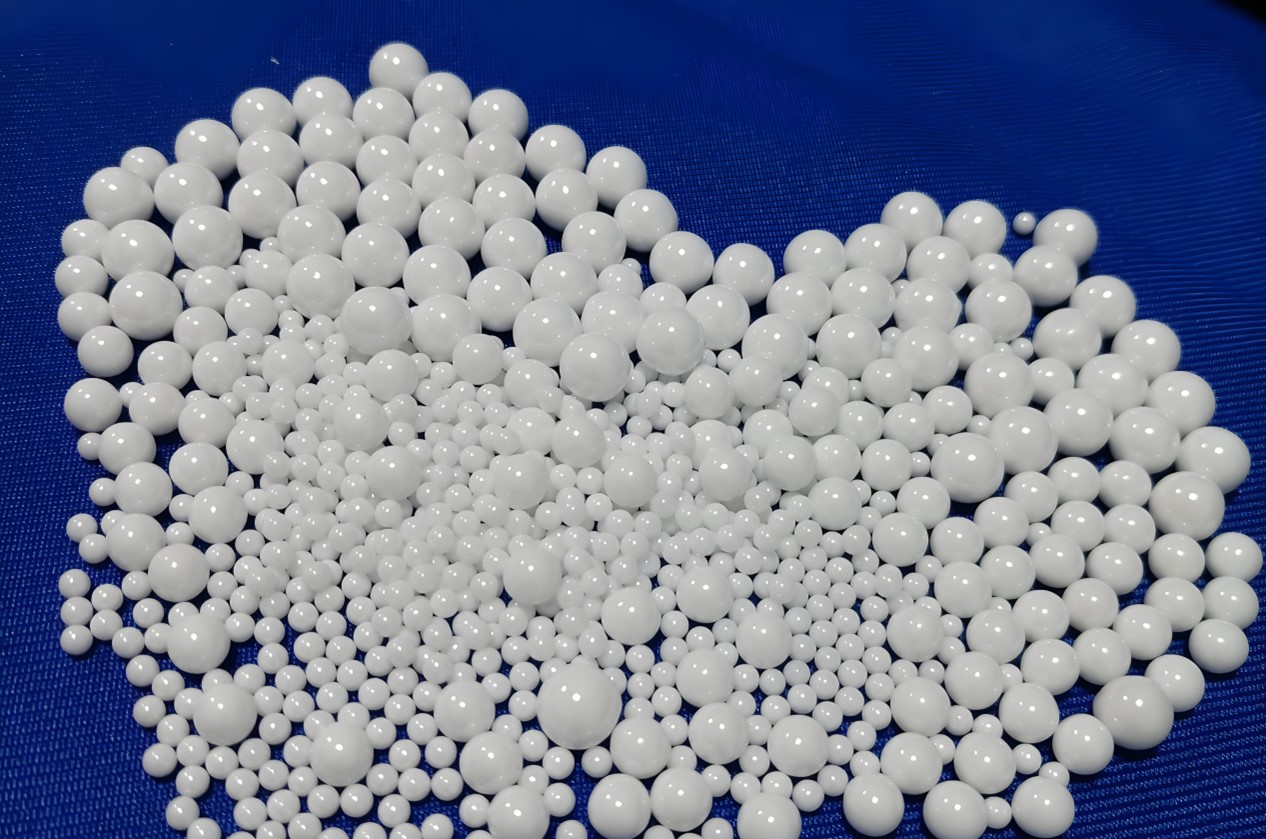

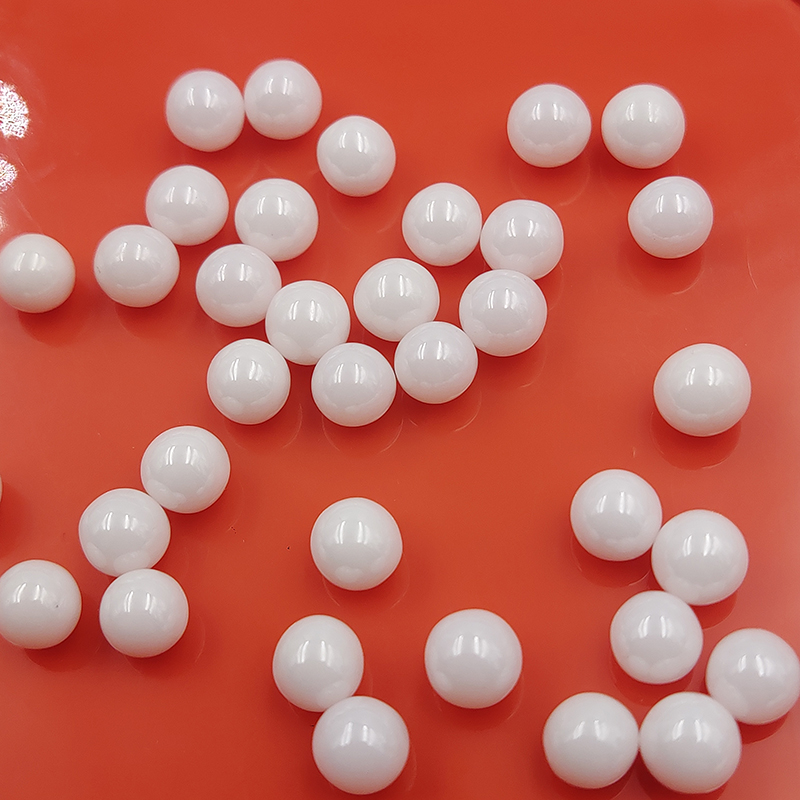

How is the performance of Nano Zirconia Beads?

Performance of nano-scale zirconia Ceramic Spheres: Outstanding performance at the microscopic scale

In the microscopic world of materials science, nano-scale Zirconia Ceramic Balls have become "star materials" in many cutting-edge fields due to their unique properties. Compared with conventional zirconia ceramic balls, nano-scale products have achieved a qualitative leap in multiple performance dimensions due to the significant reduction in particle size.

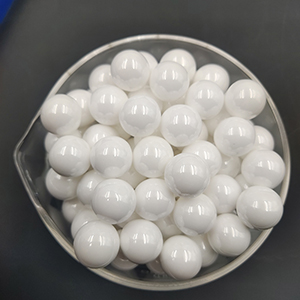

High hardness and high strength

Nanoscale zirconia ceramic balls possess astonishing hardness and strength. Due to the refinement of nanoscale grains, the number of grain boundaries has increased significantly, and the hindrance effect of grain boundaries on crack propagation has been enhanced. This enables ceramic balls to effectively disperse stress when subjected to external forces, thereby improving the overall strength. Its hardness can reach 8-9 on the Mohs scale, approaching that of natural diamond. Even when subjected to high-intensity pressure and impact, it can still maintain structural integrity. This characteristic makes it highly favored in fields with extremely high requirements for material hardness, such as precision mechanical processing and semiconductor chip manufacturing.

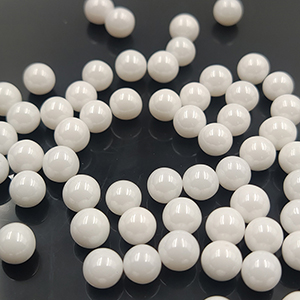

Excellent wear resistance

With the fine structure at the nanometer level, the surface of zirconia ceramic balls is smoother and denser, and the friction coefficient between them and the grinding object is significantly reduced. In long-term grinding, polishing and other application scenarios, the wear rate is much lower than that of ordinary ceramic balls, and the service life is significantly extended. For instance, during the grinding process of cathode materials for lithium batteries, nano-scale zirconia ceramic balls can ensure efficient grinding while maintaining minimal self-wear. This effectively prevents the introduction of impurities caused by the wear of the balls, ensuring the stability and consistency of product quality.

Excellent chemical stability

Nano-scale zirconia ceramic balls have extremely strong resistance to chemical substances such as acids and alkalis. Its nanostructure reduces the active sites on the material surface and lowers the possibility of reacting with chemical reagents. Whether in a strongly acidic etching solution or a strongly alkaline cleaning solution, it can maintain stable chemical properties without undergoing corrosion, dissolution or other phenomena. This outstanding chemical stability enables it to play a key role in industries such as chemical engineering and pharmaceuticals, which have strict requirements for the corrosion resistance of materials.

Good thermal stability

In high-temperature environments, nano-scale zirconia ceramic balls can still maintain stable physical and chemical properties. Its coefficient of thermal expansion is relatively low. When the temperature changes sharply, the sphere is less likely to crack or deform due to thermal expansion and contraction. Even in high-temperature environments above 600℃, it can still maintain good mechanical properties and chemical stability, and is suitable for high-temperature operation fields such as aerospace and high-temperature kilns.

High specific surface area and catalytic performance

The nanoscale size endows zirconia ceramic spheres with a relatively large specific surface area, which makes them exhibit unique advantages in the field of catalysis. A larger specific surface area means more active sites, which can effectively adsorb reactant molecules and accelerate the progress of chemical reactions. In processes such as environmental protection catalysis and petrochemical catalysis, nano-sized zirconia ceramic balls, when used as catalyst carriers or directly as catalysts, can significantly enhance catalytic efficiency and reduce reaction energy consumption.

Nano-scale zirconia ceramic balls, with their high hardness, excellent wear resistance, outstanding chemical and thermal stability, as well as unique catalytic performance, occupy an indispensable position in many high-end manufacturing and cutting-edge technology fields. With the continuous advancement of technology, its performance advantages will be further explored and expanded, bringing innovation and transformation to more fields.