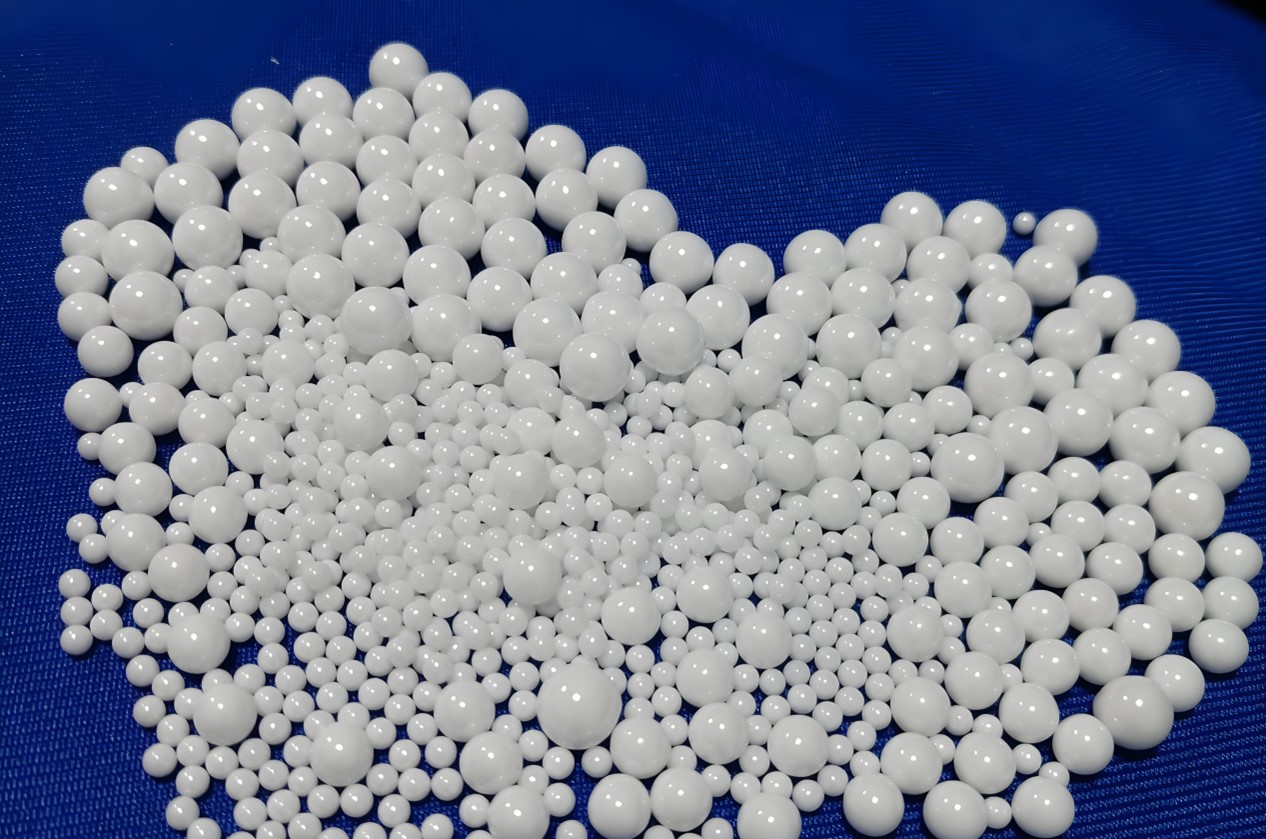

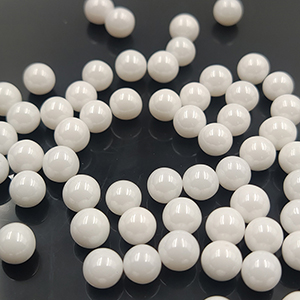

How High Temperatures Can Zirconia Beads Withstand?

Zirconia Beads, renowned for their exceptional physical and chemical properties, have become indispensable in various industrial applications, from fine grinding and dispersing in the ceramic and paint industries to high - performance polishing in the electronics sector. One of the key characteristics determining their applicability in demanding environments is their high - temperature resistance. Understanding the thermal limits of zirconia beads is crucial for optimizing their use and ensuring the longevity of equipment and the quality of processed materials.

Crystal Structure and Its Influence on Heat Resistance

The high - temperature resistance of zirconia (ZrO₂) beads is closely related to their crystal structure. Zirconia exists in three main crystalline phases: monoclinic, tetragonal, and cubic. At room temperature, pure zirconia is in the monoclinic phase. As the temperature rises, it transforms into the tetragonal phase around 1170°C and then into the cubic phase at approximately 2370°C. These phase transitions are accompanied by volume changes, which can cause cracking and failure of the material if not properly managed.

To enhance the stability and high - temperature performance of zirconia beads, they are often doped with stabilizers such as yttria (Y₂O₃), ceria (CeO₂), or calcium oxide (CaO). For example, yttria - stabilized zirconia (YSZ) is one of the most commonly used types. The addition of yttria stabilizes the cubic or tetragonal phases over a wide temperature range, preventing the detrimental monoclinic - tetragonal phase transition and significantly improving the bead's thermal shock resistance and overall high - temperature stability.

Temperature Resistance of Different Types of Zirconia Beads

Yttria - Stabilized Zirconia (YSZ) Beads

YSZ beads are highly regarded for their excellent high - temperature resistance. Depending on the yttria doping level, their performance varies.

- 3 mol% YSZ: This type, also known as tetragonal zirconia polycrystal (TZP), is mainly used in applications where high strength and toughness are required at relatively lower temperatures. It can withstand continuous operating temperatures up to approximately 800 - 1000°C. In this temperature range, its tetragonal structure remains stable, providing good mechanical properties for applications such as ceramic ball bearings and precision machining tools.

8 mol% YSZ: With a higher yttria content, 8 mol% YSZ stabilizes the cubic phase over a broader temperature range. These beads can endure temperatures up to around 1600 - 1800°C. They are widely employed in high - temperature applications like thermal barrier coatings in aerospace engines, where they protect underlying metal components from extreme heat by reducing heat transfer and maintaining structural integrity.

Ceria - Stabilized Zirconia (CeSZ) Beads

Ceria - stabilized zirconia beads offer a combination of high - temperature resistance and unique chemical properties. They can typically withstand temperatures up to 1200 - 1400°C. CeSZ beads are often used in catalytic applications and solid oxide fuel cells (SOFCs). In SOFCs, they function as electrolyte materials, operating at elevated temperatures to facilitate the efficient transfer of oxygen ions. Their ability to maintain stability and ionic conductivity within this temperature range is essential for the optimal performance of the fuel cells.

Calcium - Stabilized Zirconia (CSZ) Beads

Calcium - stabilized zirconia beads have a relatively lower cost compared to YSZ and CeSZ. They can resist temperatures up to about 1400 - 1600°C. However, they may have slightly inferior stability at higher temperatures and a higher tendency to undergo phase changes over time. CSZ beads are commonly applied in the manufacture of refractory materials, such as furnace linings and kiln furniture, where their cost - effectiveness and moderate high - temperature resistance meet the requirements of many industrial firing processes.

Application - Specific Considerations

When using zirconia beads in high - temperature applications, several factors beyond the pure temperature limit need to be considered.

- Atmospheric Conditions: The presence of certain gases in the operating environment can affect the performance of zirconia beads. For example, in a reducing atmosphere, some components of the stabilizers or the zirconia itself may react, leading to degradation. Oxidizing atmospheres are generally more favorable for maintaining the integrity of zirconia beads at high temperatures.

- Mechanical Stress: In addition to temperature, mechanical forces such as impact, abrasion, and pressure can interact with the thermal effects. High - temperature environments may reduce the mechanical strength of the beads, making them more susceptible to breakage under mechanical stress. Therefore, it is crucial to select the appropriate type of zirconia beads based on the combined thermal and mechanical demands of the application.

- Continuous vs. Intermittent Operation: The duration of exposure to high temperatures also impacts the lifespan of zirconia beads. Continuous operation at high temperatures can cause gradual degradation over time, while intermittent heating and cooling may subject the beads to thermal shock, potentially leading to cracking. Understanding the operational cycle is vital for predicting the service life of the beads and planning for maintenance or replacement.

In conclusion, the temperature resistance of zirconia beads varies depending on their composition, specifically the type and amount of stabilizers used. Yttria - stabilized zirconia beads, especially those with higher yttria doping levels, generally offer the highest temperature resistance, followed by ceria - and calcium - stabilized variants. However, the actual performance in industrial applications is also influenced by factors such as atmospheric conditions, mechanical stress, and operational patterns. By carefully considering these aspects, manufacturers can select the most suitable zirconia beads to ensure efficient operation and reliable performance in high - temperature processes.