01

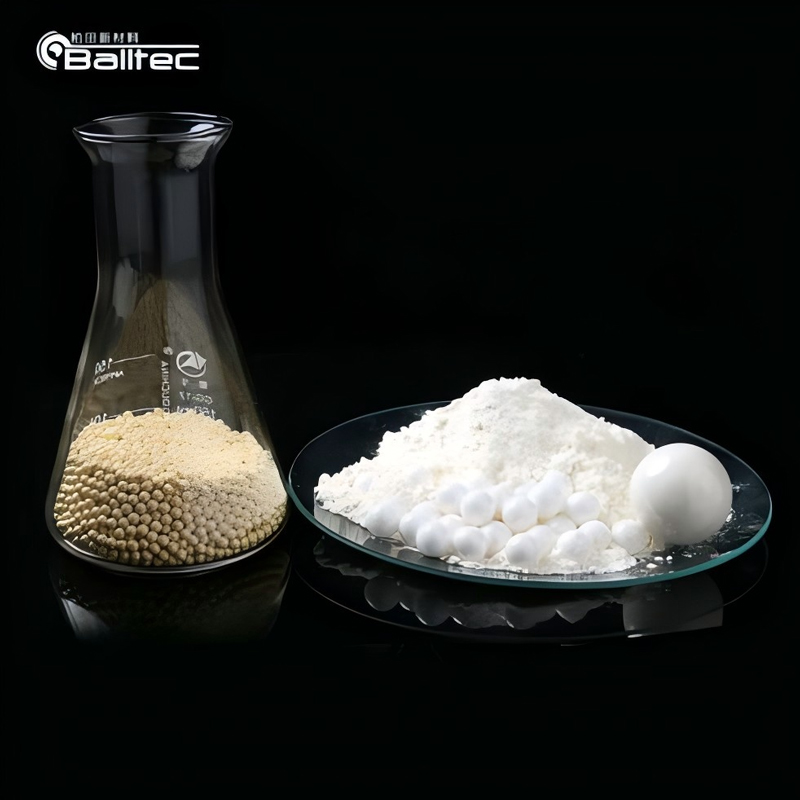

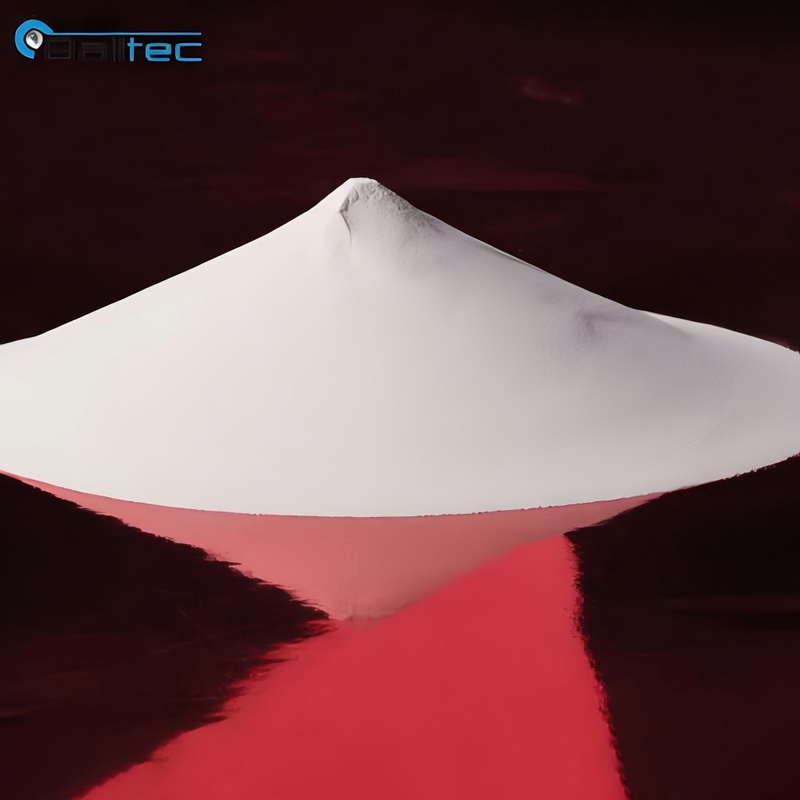

High Purity Alumina Grinding Beads/99%、99.9%、99.99% Alumina Beads

Typical purity data

| Element | Na | K | Si | Fe | Mg | Ca | Cr |

| Content (ppm) | 8 | 4 | 10 | 8 | 3 | 3 | 2 |

(U:4ppb or less,Th:5ppb or less)

Analysis by ICP

For more details technical data, Please contact sales manger or email.

Application

1)Dielectric, Piezoelectric, MLCC and other electronic materials.

2)rare earth phosphor material

3)electrode material of Lithium battery and other battery application

4)electronic ceramics, sapphire ,transparent ceramic materials

5)pigment, ink and other materials

6)high purity quartz sand, quartz crucible raw material grinding and grinding

7)medicine, pesticide, antibacterial materials, powder food type nano materials

Physical Properties

Density: 3.9

Bulk Density: 2.5

Hardness(Hv): 1100

Sphericity(%):98%

Standard Size(mm):φ0.1mm, φ0.2mm, φ0.3mm, φ0.4mm, φ0.5mm~φ30mm

Packing(kg): 25 Plastic Drum

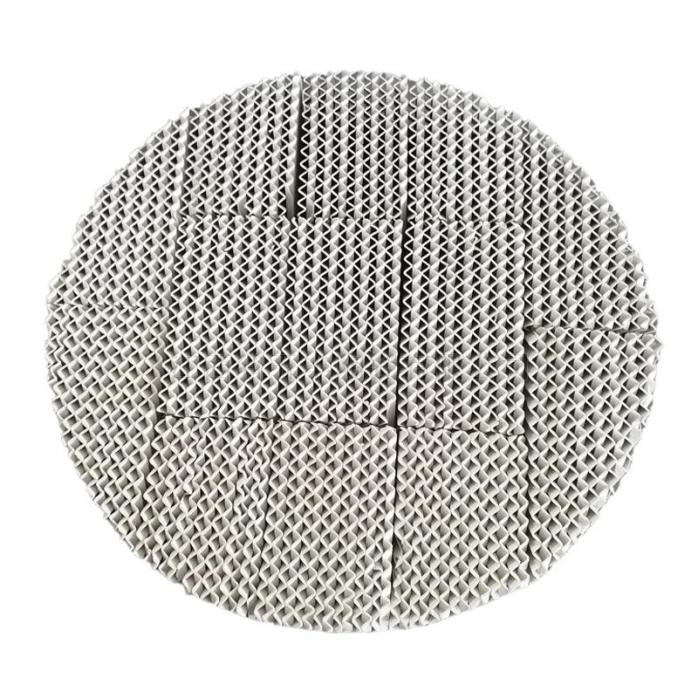

As a kind of high performance ceramic material, alumina ceramic ball has been widely used in industrial field. The choice of its forming method plays a crucial role in the performance, appearance and production efficiency of the product. The following will discuss in detail the four main forming methods of alumina ceramic balls: dry isostatic pressing, extrusion forming, pellet forming and hydraulic hard die forming.

Due to its excellent hardness and wear resistance, high purity alumina balls are often used as grinding media for precision polishing and grinding of various materials, such as glass, metals, semiconductors, etc. In semiconductor manufacturing, they are used to make wafers and surface treatments for chips.