Products

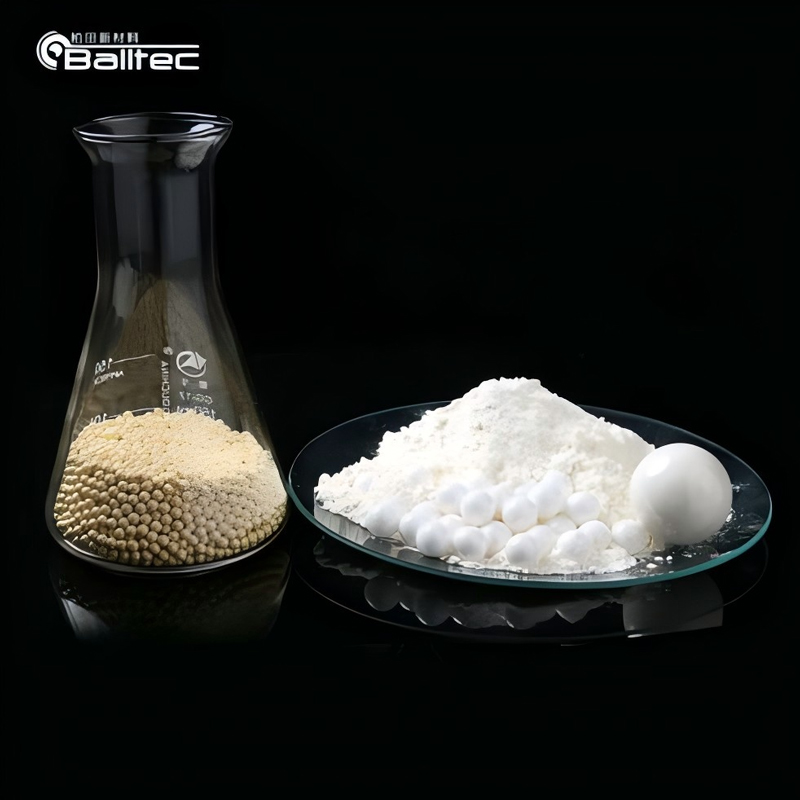

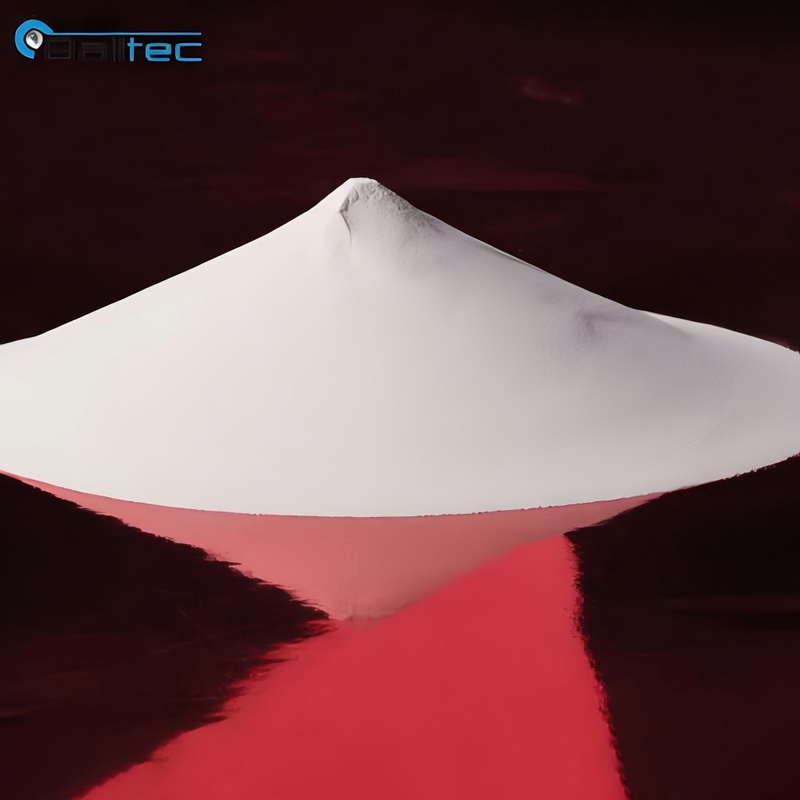

99.9% Al2O3 Grinding Bead Ceramic Grinding Media

Composition

The main component is Al₂O₃, the purity is more than 99.9%, and the impurity content is very low (such as Na, K, Si and other elements are usually in ppm). The purity of some products can reach 99.99%, and the content of radioactive isotopes (such as U and Th) is very low, which is suitable for scenes with strict purity requirements.

99% High Purity Alumina Al2O3 Grinding Ball Bead

99% purity alumina grinding ball is a kind of high purity, high wear resistance ceramic grinding medium, widely used in chemical, electronics, ceramics and other industries fine grinding and dispersion. The following is its detailed introduction, parameters and uses:

High Purity Alumina Grinding Beads/99%、99.9%、99.99% Alumina Beads

BPA

General Character

Feature

1.Excellent abrasion resistance

Abrasion resistance is higher than the zirconia beads. when the high hardness ceramics is ground,

2.High purity

The purity of the alumina beads is 99.99%or more. When grinding, no contamination other than alumina.

3.Excellent corrosion resistance

It is excellent in corrosion resistance to the acid and the alkali.

No performance deterioration in the warm water.

4.Energy saving of grinding and dispersion

The density of alumina is 2/3 of the zirconia bead, and the filling weight to the mill is 2/3.

In addition, the consumption energy when grinding can be decreased.