01

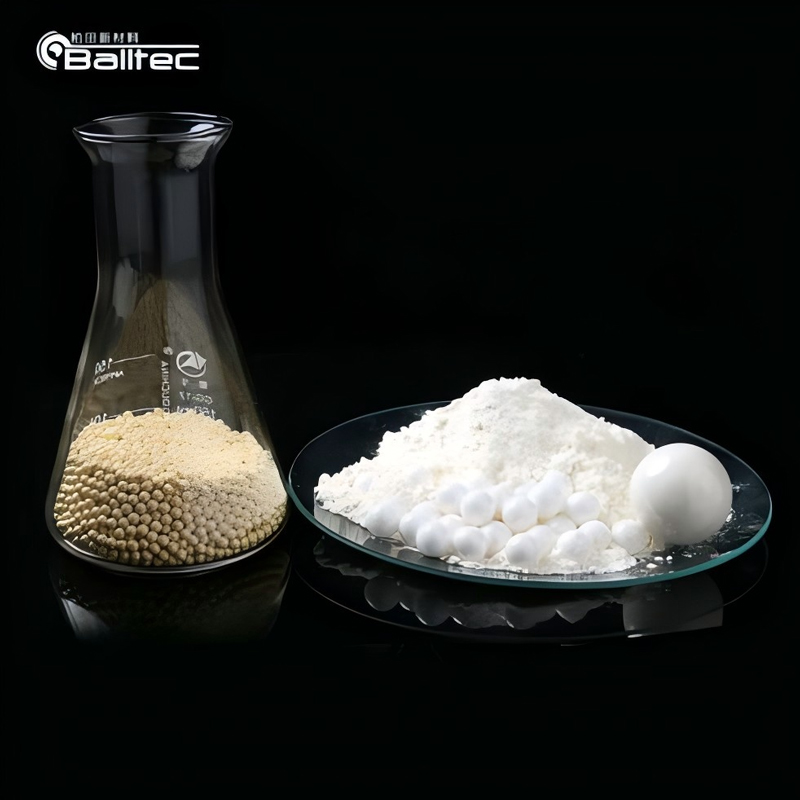

Ceria Stabilized Zirconia Bead Zirconia Sintering Beads

product description

Because the comprehensive performance of cerium zirconium beads is very strong, the grinding efficiency of high viscosity materials is very high and very uniform, the surface is smooth, easy to clean, long service life, no need to frequently mend the ball, so that the production process becomes simple and efficient, the main thing is its economy, the more wear-resistant beads the more money, most large manufacturers are using this zirconium beads as a grinding medium.

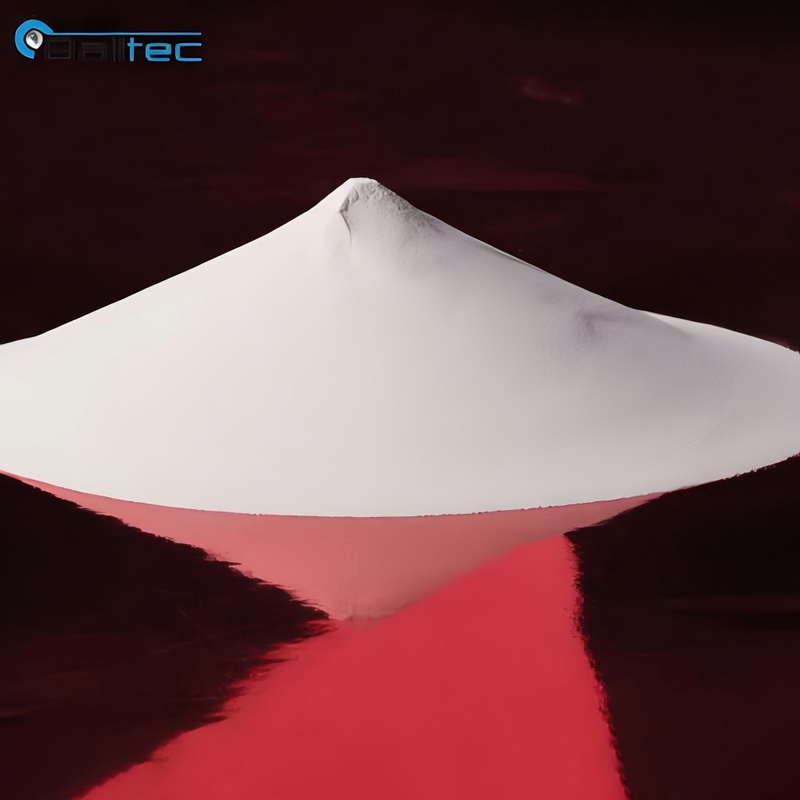

The main composition of zirconia beads is zirconia and stabilizer and a small number of other impurities, zirconia content of zirconia silicate beads is 65%, silicon content 35%, cerium stable zirconia beads zirconia content 80%, ceria content 20%, yttrium stable zirconia beads zirconia accounted for 95%, the remaining 5% is yttrium oxide, there is an alumina toughened zirconia beads, A part of alumina is added to increase the toughness of zirconium beads.

Product parameters

Bulk specific density

>3.7g/cm3 >6.1g/cm3

Vickers hardness

>1050HV

sphericity

>92%

Package size

plastic bucket/ton bag 0.4-7.0mm

More common in production is the two-stage ratio and multi-stage ratio, the general multi-stage ratio follows, large, small ball, middle ball, that is, "less two ends, more middle" principle; The so-called two-stage ball method is to use two different sizes and large diameters of zirconium balls for grading.

The determination of the large ball diameter depends on the size of the ball mill, the particle size of the grinding material and the grindability. Generally, the second level ball diameter in the multi-level ball matching shall prevail. The diameter of the ball is determined by the size of the space between the big balls, that is, by the diameter of the big ball. Under normal circumstances, the diameter of the ball is 20%-30% of the diameter of the large ball.