01

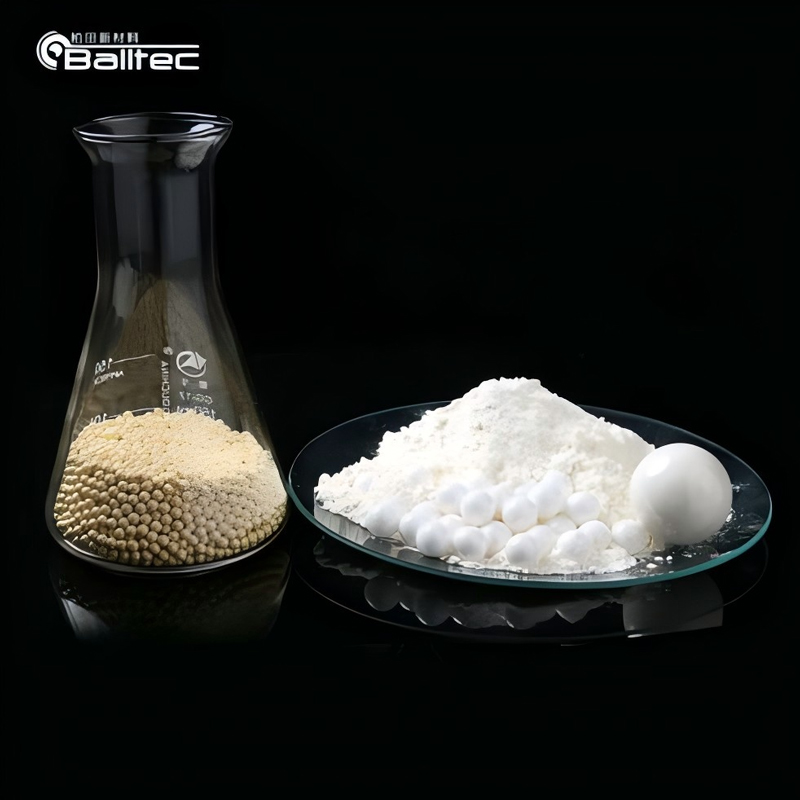

Ceria Stabilized Zirconia Bead/Cerium Zirconia Oxide Bead/Ce-TZP Bead

Feature & Application

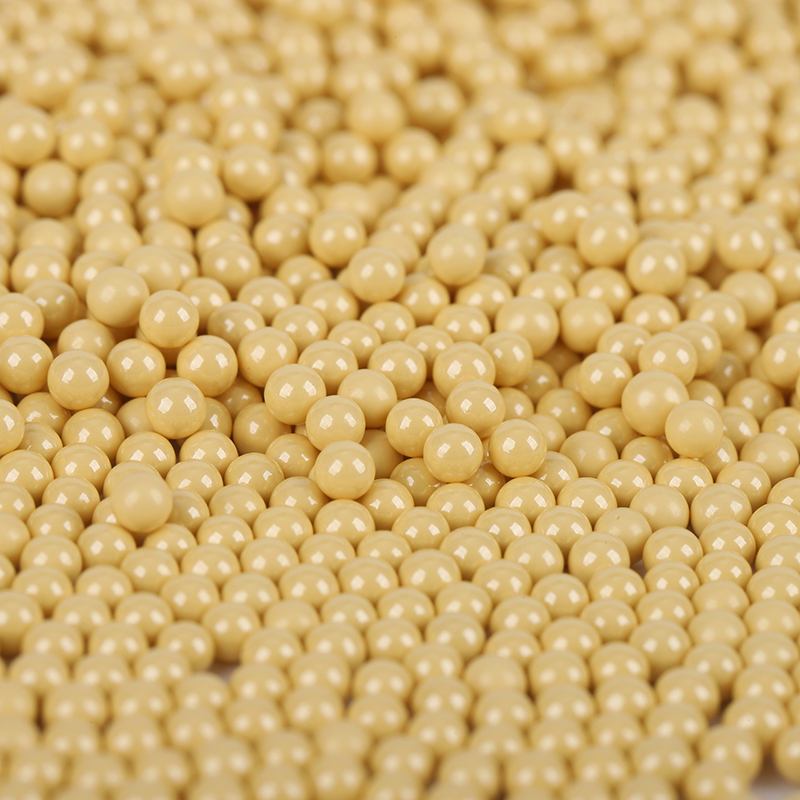

With special process, the internal structure of the beads is uniform and compact.

Good stability, strong acid&alkali resistance.

Highest density, significantly improving grinding efficiency than other ceramic beads.

Application

It is mainly applied to ultra fine grinding and dispersion of materials that require high viscosity and high hardness, such as paint, ink, paint, paper, metal, non-metal and rare earth materials.

Chemical Composition

| Chemical Compostion | ZrO2 | CeO2 | AL2O3 | Fe2O3 | SiO2 | TiO2 | MgO | Na2O3 |

| % | ≥85 | ≤15 | 0.3±0.1 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Physical Properties

Density(g/cm3):6.2

Bulk Density(g/cm3):3.8

Hardness(Hv):1000

Sphericity(%):98%

Standard Size(mm): 0.50,0.60, 0.80, 1.00, 1.20, 1.50,1.70,2.00,~10mm

Packing(kg): 25kg Plastic Drum

Application: Can be used in horizontal sand mill, vertical sand mill, basket sand mill, ball mill, vibration mill material grinding.

Materials: paint, textile, pigment, printing and dyeing, magnetic materials, ceramics, medicine, food, cosmetics, etc.

Cerium oxide content: 20%

Ceria stabilized zirconia beads are refined using a patented titration rolling molding process, and the formulation of about 20% of rare earth ceria gives the beads a greater proportion of zirconium series grinding media. The bead always maintains a smooth spherical surface during use due to the internal consistent and fine zirconia microcrystals, which is also a guarantee of low bead wear and low energy consumption of the equipment. It is recommended to be widely used for grinding high solid content and high viscosity slurry.

Product features

High specific gravity: increased grinding efficiency and reduced bead delamination and toppling in the sander;

Consistently smooth working surface: reduce energy consumption; Avoid wear of beads and equipment contact parts;

Matching equipment: horizontal sand mill with high energy density and vertical sand mill with large aspect ratio.