Products

Wear & Heat Resistant Ceramic Structured Packing

Ceramic corrugated packing, as an innovative regular packing material, is composed of numerous uniformly geometrically shaped packing units arranged in an orderly manner. Thanks to the unique structure of the ceramic material, this packing exhibits excellent hydrophilicity. Its surface can form a thin liquid film accompanied by turbulence, while the gas flows in a tortuous channel in an inclined manner, which not only promotes the smooth flow of the gas but also does not hinder its passage. This makes ceramic packing comparable to metal packing in terms of performance, and even has more advantages in terms of corrosion resistance and high-temperature resistance. Moreover, its superior wettability on the surface structure can accelerate the liquid flow, further reducing the liquid retention of the packing, and thereby reducing the risks of overheating, polymerization and coking.

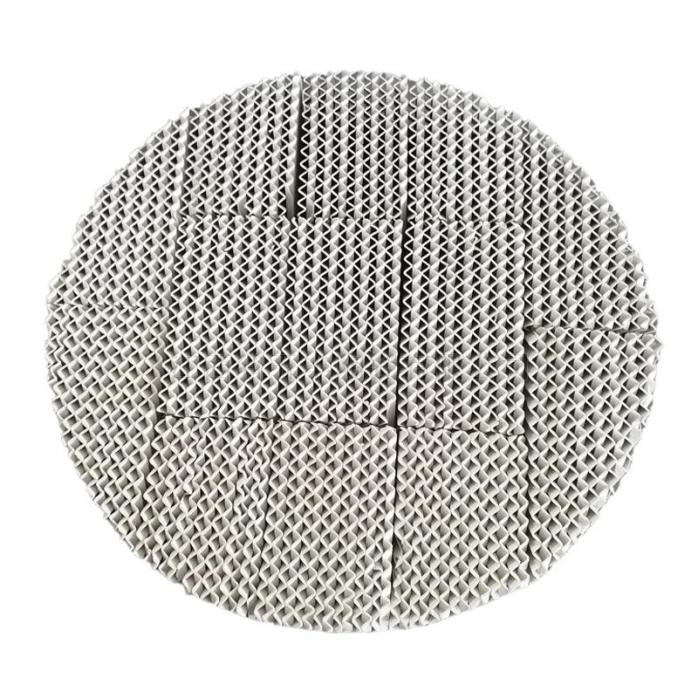

Infrared Ceramic Burner Plate Special Porous Ceramic Plate for Infrared Burner Gas Heater Ceramic Plate Gas Water Heaters Infrared Cooker Electric Ceramic

ICBP

Features:

High mechanical Strength;

Large specific surface area;

Geometric size regular;

Uniform radiant burning;

Excellent thermal shock resistance;

Save up to 30~50% energy cost;

Burn without flame, high burning efficiency, low noise;

Has no carbon combustion channel non clogging;

Reduce the harmful gas such as CO, NOx, etc more than 90%.

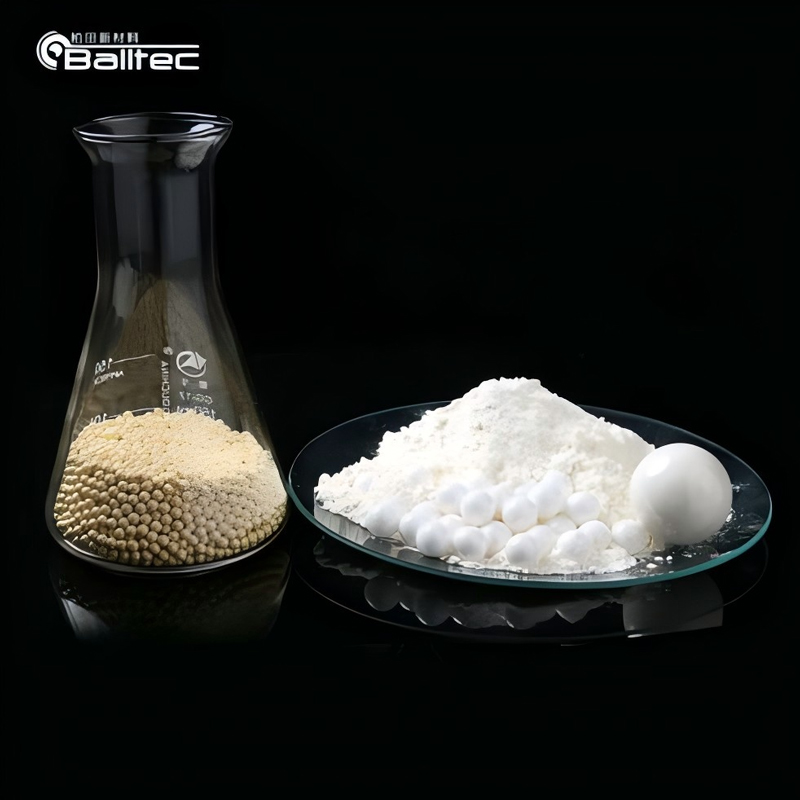

Ceramic Foam Filter High Strength Heat Resistant Honeycomb Porous Zirconia Ceramic Foam Filter

CFF

Features:

Ball-tec ceramic foam filter with a high temperature, corrosion resistance, resistance to molten metal erosion, high strength, high pass rate, and the characteristics of the large surface area is mainly used in the field of metallurgy and casting metal liquid filtration and purification. The flow of a mixture of molten metal passes through foam ceramic porous structure becomes uniform smooth clean molten metal filled the mold to remove the molten steel in the fineness of micron inclusions and some parcels gas reduce the erosion of the sand mold, and reduce product obsolescence rate. Ceramic foam filters can be made of different pore size and porosity, in order to obtain satisfactory filtration effect.