In the dynamic landscape of industrial applications, the significance of 95 Zirconium Beads has gained notable attention among manufacturers and researchers alike. These specialized beads, renowned for their exceptional hardness and durability, are increasingly utilized in processes such as grinding and polishing. According to a recent market research report, the demand for high-performance grinding media, including zirconium-based products, is projected to grow at a CAGR of over 6% through the next five years, highlighting the substantial role that 95 Zirconium Beads play in enhancing efficiency and product quality across various sectors.

The benefits of utilizing 95 Zirconium Beads extend beyond mere performance; their chemical resistance and low wear rate make them ideal for use in challenging environments. Industry data suggests that the adoption of zirconium beads in the milling process can lead to a significant reduction in contamination during grinding, thus ensuring the purity of the final product. As manufacturers seek to optimize their operations, understanding the best uses and advantages of 95 Zirconium Beads becomes crucial. This guide offers insights into these applications, paving the way for informed purchasing decisions that align with evolving industry standards and customer expectations.

95 Zirconium beads are versatile materials used across various industries due to their unique properties, such as high resistance to corrosion and excellent durability. In the dental industry, they are commonly utilized for making crowns and bridges due to their biocompatibility and aesthetic appeal. These beads provide superior strength while ensuring a natural look, making them ideal for long-lasting dental restorations.

In the energy sector, 95 Zirconium beads serve critical roles in nuclear reactors. Their ability to withstand high temperatures and neutron absorption makes them essential for fuel fabrication and cladding materials, enhancing the safety and efficiency of nuclear power plants. Additionally, the beads are increasingly used in filtration applications, where their chemical stability allows for effective separation processes in both industrial and environmental contexts.

Tips: When selecting 95 Zirconium beads, consider their intended application. For dental uses, ensure the beads meet relevant health standards for biocompatibility. In industrial applications, evaluate the operating conditions, such as temperature and chemical exposure, to choose the most suitable grade for your needs. Always consult with suppliers for specifications that align with your requirements.

95 zirconium beads offer numerous benefits across various applications, making them a versatile choice in both industrial and artistic settings. One key advantage is their exceptional durability. These beads are resistant to wear and tear, ensuring longevity even in high-stress environments. This resistance also means they maintain their appearance and finish over time, making them ideal for use in jewelry making and decorative pieces where lasting quality is essential.

Additionally, 95 zirconium beads exhibit excellent thermal stability, allowing them to perform reliably in high-temperature situations. This property is particularly beneficial in applications like grinding and mixing, where heat generation can impact other materials. Furthermore, they are chemically inert, reducing the risk of contamination in sensitive processes, such as in laboratories or food processing. The combination of these features not only enhances performance but also assures users of the safety and integrity of their final products.

| Dimension | Description | Benefits | Best Uses |

|---|---|---|---|

| Material Composition | 95% Zirconium | High strength and durability | Industrial applications |

| Size Range | 1mm - 10mm | Versatile usage across different industries | Medical devices, dental applications |

| Color | Shiny silver | Aesthetic appeal | Jewelry and decorative items |

| Density | 6.52 g/cm3 | Weight management in applications | Equipment manufacturing |

| Thermal Stability | High temperature resistance | Reliable performance in extreme conditions | Aerospace components |

| Corrosion Resistance | Excellent resistance | Longevity and reduced maintenance | Chemical processing |

| Environmental Impact | Non-toxic | Safe for various applications | Wastewater treatment |

When considering the purchase of 95 zirconium beads, there are several key factors that should guide your decision-making process. First and foremost, the quality of the beads is crucial. Look for beads that are manufactured under strict quality control standards, ensuring their uniformity in size and shape. High-quality beads will not only enhance the aesthetic appeal of your projects but will also provide better durability and performance, especially in applications requiring high resistance to wear and corrosion.

Another important aspect to evaluate is the specific application for which the beads will be used. Different projects may demand various characteristics from the beads, such as size, density, and surface texture. For instance, if you are using the beads in a high-energy milling process or in specific artistic endeavors, you may need to select beads with particular dimensions or coating features. Understanding the demands of your project will help you choose the most suitable zirconium beads to maximize effectiveness and efficiency, ensuring the best possible results. Additionally, consider the availability and sourcing of the beads, as reliable suppliers can significantly influence both the quality and the overall cost of your project.

In the realm of industrial applications, 95 zirconium beads have gained prominence due to their unique properties and advantages over other materials. A comparative analysis reveals that these beads offer superior durability and chemical resistance, making them an ideal choice for applications in abrasive environments. According to a report by the International Journal of Materials Science, zirconium beads exhibit a hardness rating that often exceeds that of steel balls by up to 30%, which significantly enhances their lifespan when used in grinding and milling processes.

Additionally, when contrasting 95 zirconium beads with aluminum oxide and glass beads, it becomes clear that zirconium's lower density contributes to reduced wear on machinery. As noted in a study conducted by the Global Institute for Powder Metallurgy, zirconium beads can increase efficiency in grinding operations by up to 20% due to their enhanced performance in high-energy mills. This efficiency is crucial in settings where production speed and quality are paramount, such as in the pharmaceutical and cosmetic industries, where precision and consistency are non-negotiable. By choosing 95 zirconium beads over alternative materials, industries can achieve not only cost savings due to reduced replacement frequency but also improvements in product quality and process effectiveness.

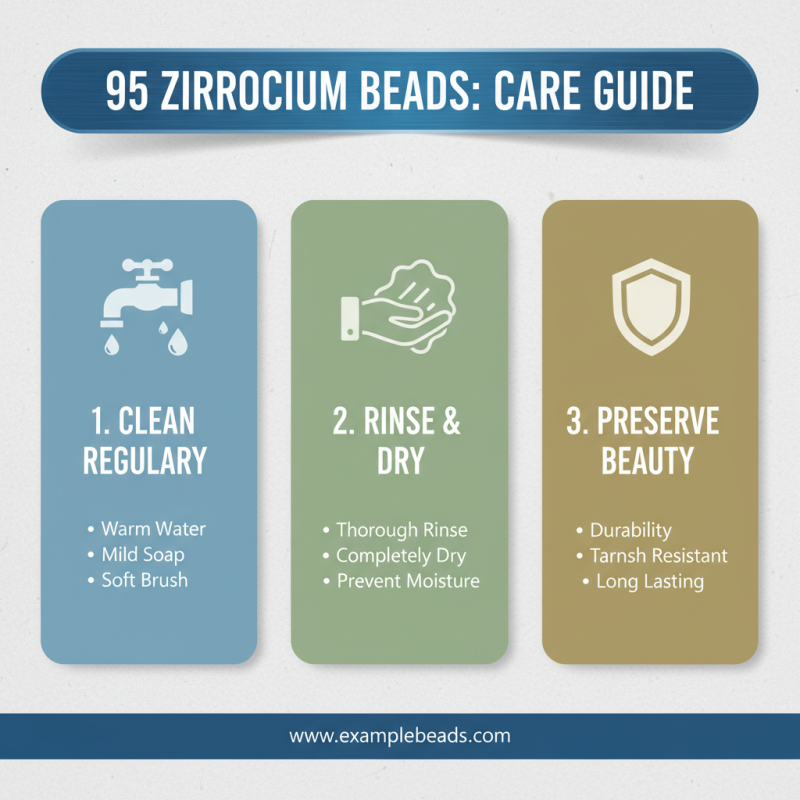

When it comes to maintaining and caring for 95 zirconium beads, the right practices can help preserve their beauty and longevity. These beads are known for their durability and resistance to tarnish, but proper care is still essential. Regular cleaning is key; simply rinse them with warm water and a mild soap solution, then gently scrub with a soft brush to remove any dirt or oils. Be sure to thoroughly rinse and dry the beads completely to prevent any moisture-related issues.

Another important aspect of caring for 95 zirconium beads is storage. To avoid scratches or damage, store them in a soft cloth pouch or a separate compartment in a jewelry box. This prevents them from coming into contact with harder materials that could cause abrasions. Also, consider keeping them away from direct sunlight and humidity, which can affect their appearance over time.

**Tips**: It’s advisable to avoid exposing zirconium beads to harsh chemicals, including those found in household cleaners or beauty products, as they may compromise the integrity of the beads. If your beads feature any additional materials, like stringing or adhesives, keep an eye on those components for wear and replace them as necessary to ensure the overall longevity of the piece.