Zirconia Ball Media has become essential in various industries due to its unique properties. This advanced material, known for its hardness and durability, is widely adopted in grinding and polishing applications. According to a report from the Global Zirconia Ball Media Market, it is projected to grow by 6.5% annually through 2025. This suggests a rising demand for high-quality abrasives.

Expert Dr. Emily Thompson notes, “Zirconia Ball Media enhances efficiency and quality across multiple sectors.” This highlights its importance in manufacturing processes. The versatility of this media makes it suitable for applications in ceramics, electronics, and metalworking. Industries notice improved surface finishes and reduced contamination when using zirconia.

However, the challenges remain. Sourcing high-quality zirconia can be inconsistent. Businesses must evaluate their suppliers to ensure reliability. Understanding the true benefits and addressing these limitations will ultimately lead to better outcomes. The conversation around Zirconia Ball Media is critical for future innovations and improvements in various applications, emphasizing the need for industry adaptability.

Zirconia ball media is a highly durable material used in various industries. Its composition primarily includes zirconium dioxide, which provides excellent hardness and chemical stability. This makes zirconia balls resistant to wear and tear, suitable for demanding environments.

The properties of zirconia ball media offer significant advantages. They exhibit high density and strength, ensuring effective grinding and milling processes. These balls can minimize contamination during operations, which is crucial in sensitive applications. Their low thermal conductivity helps maintain temperature stability, preventing material damage.

However, challenges remain. The cost of zirconia balls can be higher than alternatives. This factor leads some industries to reconsider their choices. In some cases, the need for specialized handling increases operational complexity. Analyzing the trade-offs is essential for making informed decisions. Understanding these details can lead to better resource management and efficiency.

Zirconia ball media is increasingly popular across various industries. Its unique properties offer significant advantages for processes requiring high precision and durability. One of the key sectors utilizing this material is the ceramics industry. Manufacturers often choose zirconia balls for grinding and milling. They enhance the quality of ceramic products. However, achieving the desired granulation can sometimes be challenging. Finding the right size and density is crucial.

Another important field is the electronics industry. Zirconia balls can optimize the performance of devices by improving the grinding of components. They help ensure uniformity in the production of electronic circuits. Yet, there can be issues with wear rates over time. Monitoring the lifespan of these media is necessary for consistent output.

In the pharmaceutical industry, zirconia ball media offers great benefits in drug formulation. Their inert nature minimizes contamination risks. Using them leads to purer end products. On the downside, not all formulations can benefit equally. Tailored approaches may be essential. This means continual reassessment of methods to maximize effectiveness.

Zirconia ball media has transformed the grinding and dispersion landscape across various industries. Its high density and hardness make it ideal for these applications. According to a market report by Grand View Research, the global ceramic balls market is projected to reach $1.9 billion by 2025. This growth signifies the increasing reliance on zirconia balls for efficient production.

In grinding operations, zirconia balls offer superior performance. Their low wear rates lead to longer service life and reduced costs. Some reports suggest wear rates can decrease by up to 30% compared to traditional media. This durability is crucial for industries like automotive and electronics, where precision is key. However, some users have noted inconsistencies in performance, which can create challenges during scale-up.

Dispersion applications also benefit from zirconia media. They enhance product quality by providing narrower particle size distributions. The high energy transfer improves dispersion efficiency in paint and ink production. Yet, a few studies indicate that improper selection of the media size can lead to suboptimal results. Adjusting variables remains a critical aspect that requires further investigation to ensure optimal outcomes.

Zirconia ball media has gained popularity in various industries due to its unique properties. It offers superior hardness and wear resistance compared to traditional media. This makes it ideal for high-energy milling applications. The smooth surface of zirconia balls ensures consistent grinding and reduces contamination. This is crucial in industries where purity is paramount.

When comparing zirconia balls with other grinding media, differences become evident. For example, ceramic media may be more cost-effective. However, they often wear out quicker and require more frequent replacements. Steel balls may initially seem durable, but they can introduce metallic ions into the product, compromising quality. Zirconia balls eliminate these concerns with their inert composition.

In certain cases, challenges arise when using zirconia media. Their higher cost may deter small businesses. Additionally, they require precise handling to avoid cracking. An understanding of these nuances helps industries make informed choices. The right media can greatly enhance production efficiency and product quality. Industry leaders often reflect on these factors when evaluating their options.

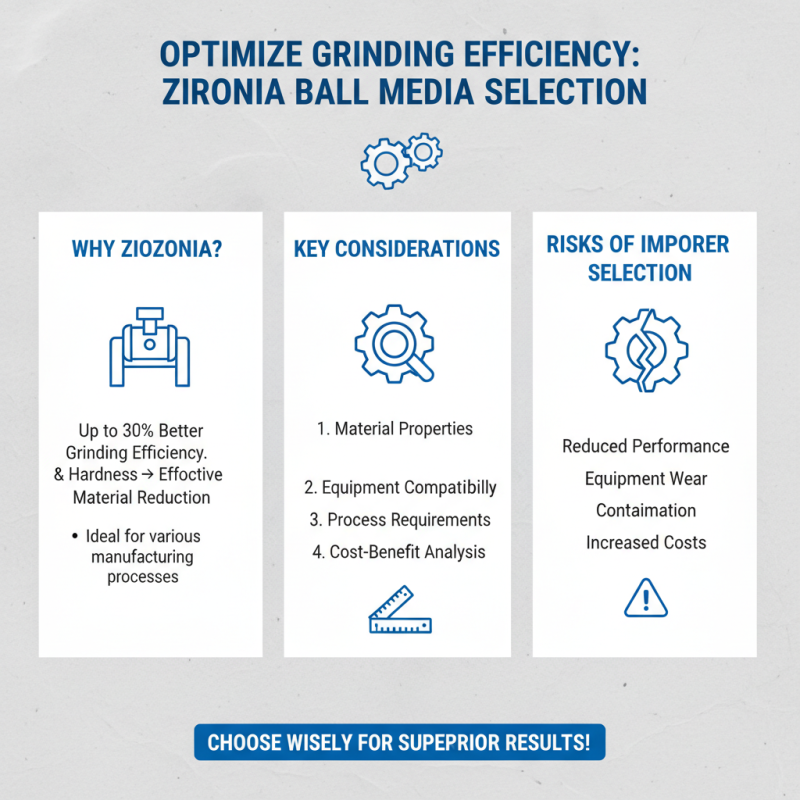

When selecting zirconia ball media, it is vital to consider the specific requirements of your manufacturing process. Research indicates that zirconia balls can provide up to 30% better grinding efficiency compared to traditional media. This efficiency is largely due to their high density and hardness, which allows for more effective material reduction. However, improper selection can lead to equipment wear or suboptimal performance.

The size of the zirconia balls also plays a critical role. A report shows that smaller balls are ideal for fine grinding, while larger sizes are better for coarse material. Knowing when to use which size can prevent wasted resources. It's common for manufacturers to overlook the importance of media size, leading to potential inefficiencies. Additionally, calibration of the amount of media used should not be taken lightly, as this impacts both the quality of the output and the lifespan of the machinery.

Proper maintenance of the zirconia media is another often-neglected aspect. Regular inspections can prevent costly downtimes and ensure consistent performance. Data suggests that neglected media can lose up to 25% of its effectiveness. A reflective approach to using zirconia balls could lead to better operational results and improved cost efficiency in the long run.