In the world of advanced material processing, the selection of the right grinding media is crucial for optimizing efficiency and durability. Yttria Zirconia Beads have emerged as a top choice for industries aiming for high-performance grinding operations. According to a recent market report by Research and Markets, the global demand for ceramics and grinding media is projected to grow at a CAGR of 6.3% through 2025, significantly driven by the increasing need for finer particle sizes in various applications, such as paints, coatings, and pharmaceuticals.

Yttria Zirconia Beads, known for their exceptional hardness and toughness, enable superior grinding performance compared to traditional media types. Their low wear rate and high density contribute to prolonged service life, resulting in cost savings and improved product quality. The latest studies highlight that the use of Yttria Zirconia Beads can enhance grinding efficiency by up to 30%, making them a strategic investment for companies committed to maintaining a competitive edge in a resource-intensive market.

As manufacturers continue to prioritize innovation and sustainability, understanding how to choose the right Yttria Zirconia Beads will be pivotal in harnessing their full potential for grinding applications.

When selecting yttria zirconia beads for grinding applications, several critical factors can significantly influence performance and durability. First, the size and uniformity of the beads are essential as they directly correlate with grinding efficiency. According to a report by the Advanced Material Research Journal, optimal bead sizes typically range from 0.2 to 1.0 mm for most applications, resulting in enhanced particle size reduction and improved dispersion quality.

Another vital consideration is the content of yttria in the zirconia beads. Research indicates that beads with a higher yttria content (typically around 10-20%) provide superior toughness and wear resistance. A study published in the Journal of Materials Science highlighted that yttria-stabilized zirconia beads exhibit lower fracture rates and longer operational life compared to their competitors, making them ideal for high-impact milling processes in industries such as ceramics, paint, and ink manufacturing.

Lastly, the specific application environment should be evaluated. Beads used in abrasive or high-viscosity liquids require different properties than those utilized in more standard conditions. Matching the bead composition and characteristics to the intended use ensures optimal grinding efficiency, as noted in various industry reports. This tailored approach can substantially reduce downtime and increase cost-efficiency in production processes.

Yttria zirconia beads have gained recognition for their exceptional benefits in various grinding applications. Their wear resistance characteristics are a crucial advantage, especially when subjected to real milling conditions. Studies demonstrate that these beads maintain their integrity and performance over extensive grinding processes, making them ideal for producing finely milled products. The stability of particle suspensions, particularly in drug formulation and organic crystalline food processing, is essential for ensuring product quality. Yttria zirconia beads contribute significantly to this stability, reducing particle agglomeration and promoting uniform dispersion.

Additionally, the increasing demand for durability in grinding media highlights the importance of selecting the right materials for specific applications. With advancements in production techniques, manufacturers have improved the quality and consistency of yttria zirconia, ultimately enhancing grinding efficiency. As industries continue to prioritize high-performance materials, yttria zirconia beads represent a smart investment for achieving superior results in grinding operations while minimizing wear and prolonging equipment lifespan.

When selecting yttria zirconia beads for grinding applications, understanding the impact of sizing and shape variations is crucial for optimizing grinding performance. The diameter of the beads plays a pivotal role in determining the efficiency of the grinding process. Smaller beads tend to provide a higher surface area, enhancing the grinding action and enabling the breakdown of finer particles. Conversely, larger beads are more effective for coarser materials, as they deliver greater force and allow for faster material removal. Therefore, the choice of bead size should align with the specific application requirements to achieve the desired results.

In addition to size, the shape of the zirconia beads also significantly influences grinding performance. Spherical beads are commonly preferred due to their uniform motion and ability to minimize wear on both the beads and the milling equipment. However, variations in shape, such as cylindrical or triangular beads, can offer unique advantages depending on the grinding medium's properties and the desired particle size distribution. Selecting the appropriate bead shape can enhance the fluid dynamics within the grinding chamber, leading to more efficient energy transfer and improved overall grinding effectiveness.

When selecting yttria zirconia beads for grinding applications, durability and wear resistance are critical factors influencing productivity and cost-effectiveness. According to a report by the International Journal of Advanced Manufacturing Technology, yttria-stabilized zirconia exhibits significantly lower wear rates compared to traditional ceramic media, with wear rates measured as low as 0.03 grams per hour under comparable conditions. This enhanced durability ensures that the beads maintain their structural integrity over prolonged use, resulting in reduced operational downtime and replacement costs.

**Tips:** To maximize wear resistance, consider the size and density of the beads. Smaller beads often provide finer grinding results, while denser materials enhance durability. Additionally, look for suppliers that provide comprehensive data on the mechanical properties of their products, as this information can be crucial in optimizing your grinding processes.

Evaluating the wear resistance of yttria zirconia beads can also be accomplished through various testing methods. The use of a Ball-on-Disk wear test outlined in industry standards demonstrates that zirconia beads possess a hardness of approximately 1200 HV (Vickers), competing favorably against steel and glass media. Selecting beads with such superior hardness translates to longer lifespans in milling applications, which is especially vital in industries requiring high precision and consistency.

**Tips:** Ensure to conduct tests that replicate actual working conditions to accurately gauge performance. Additionally, factor in the environmental conditions of your operation, as chemical exposure can also impact bead longevity.

| Bead Type | Diameter (mm) | Density (g/cm³) | Fracture Toughness (MPa·m1/2) | Wear Rate (g/hour) | Applications |

|---|---|---|---|---|---|

| ZrO2 + Yttria | 1.0 | 6.0 | 7.5 | 0.05 | Ceramics, Chemicals |

| ZrO2 + Yttria | 2.0 | 6.0 | 7.0 | 0.04 | Paints, Inks |

| ZrO2 + Yttria | 3.0 | 6.1 | 8.0 | 0.03 | Pharmaceuticals, Food |

| ZrO2 + Yttria | 4.0 | 6.1 | 8.5 | 0.02 | Metals, Advanced Materials |

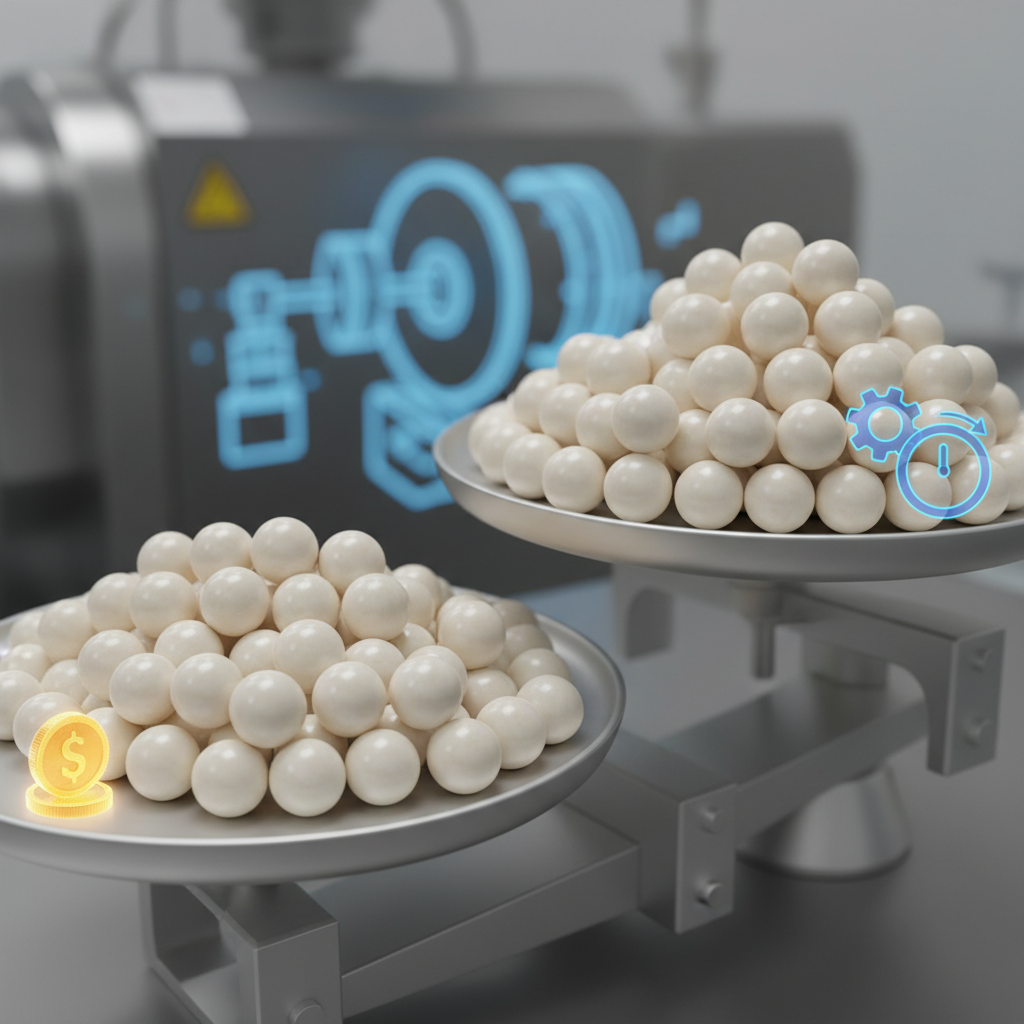

When selecting yttria zirconia beads for grinding processes,

cost-effectiveness emerges as a crucial aspect to consider.

While high-quality materials often come with a premium price, it’s essential to assess the

long-term benefits these beads offer in terms of durability

and grinding efficiency. Investing in superior beads can lead to

reduced wear and tear on both the beads and the grinding equipment, ultimately lowering

replacement costs and minimizing downtime.

Moreover, balancing quality and price involves evaluating the

specific requirements of your application. For instance, if your grinding needs demand

finer particle sizes or higher throughput, opting for

more advanced variants of yttria zirconia beads may yield better results, justifying the

higher initial investment. It’s vital to conduct thorough research and possibly trial

different products to find a blend of quality and pricing that meets your operational goals,

ensuring that you achieve optimal performance without straining your budget.