Zirconia Silicate Beads are increasingly popular in the grinding industry due to their superior performance. According to recent market research, the demand for effective grinding media has surged, with zirconia silicate beads accounting for a substantial market share. These beads exhibit exceptional hardness and toughness, making them suitable for various applications, from paints to ceramics.

The ceramic industry alone is projected to grow significantly, driven by the need for high-quality materials. Zirconia Silicate Beads facilitate finer particle sizes, enhancing the overall quality of the final product. However, achieving optimal results requires understanding the proper usage techniques. There are challenges, such as selecting the right bead size and maintaining an appropriate ratio in the grinding mixture.

Users may overlook mechanical properties when sourcing grinding media, which can lead to inefficiencies. A focus on the attributes of Zirconia Silicate Beads, such as their density and wear resistance, is crucial. Without this awareness, companies may not fully realize their potential in maximizing productivity.

Zirconia silicate beads are a popular choice in the grinding industry. Their unique composition plays a crucial role in their effectiveness. These beads combine zirconium dioxide and silica, creating a durable and wear-resistant material. This composition results in lower hardness compared to other grinding media, but they excel in fine milling applications.

Studies show zirconia silicate beads can improve milling efficiency by up to 35%. Their spherical shape allows for consistent contact with the material being processed. This results in a more uniform particle size and better product quality. However, some users report issues with bead breakage during high-performance tasks. This challenge requires users to carefully consider the operational parameters.

Moreover, the ecological impact of zirconia silicate beads is worth noting. These beads produce minimal waste, unlike some alternatives. However, the production process may create a carbon footprint that raises environmental concerns. These considerations are essential in making the right choice for sustainable grinding. Users should always balance performance with environmental responsibility.

Zirconia silicate beads are popular in the grinding industry. Their unique properties are key to their effectiveness. These beads are made from a mixture of zirconia and silica. This combination ensures toughness and resistance to wear. According to industry reports, they can enhance grinding efficiency by up to 30%. This is particularly useful in applications where fine grinding is essential.

The mechanism of grinding with zirconia silicate beads involves both impact and attrition. When these beads collide with materials, they create intense pressure. This pressure breaks down particles efficiently. The beads also create a fluid motion that carries the material, leading to a more uniform grind. This dual action is essential for achieving desired particle sizes. However, improper bead size or insufficient quantity can lead to suboptimal results, necessitating careful consideration.

Another factor to consider is the bead size distribution. A uniform size distribution can enhance grinding outcomes. However, variability in sizes can lead to uneven wear. This issue is often overlooked but can affect performance. A well-optimized bead mix can directly correlate with productivity levels. These nuances demonstrate that effective grinding is not just about the beads; it's about how they interact with materials.

Zirconia silicate beads are an innovative choice for grinding applications in various industries. They provide a unique blend of hardness and toughness, making them effective in milling operations. Their density and wear resistance allow for reduced contamination and longer service life. Reports indicate that using these beads can enhance grinding efficiency by up to 30%. This is particularly valuable in the ceramics and paint industries, where precise particle sizes are crucial.

When considering the optimal applications for zirconia silicate beads, ceramic processing stands out. They effectively reduce the size of raw materials, ensuring better product quality. In paint production, these beads help achieve uniform dispersion of pigments. Their spherical shape promotes consistent grinding, enhancing overall output.

Here are some tips for utilizing zirconia silicate beads effectively. Start with a smaller bead size for finer materials. Monitor the bead’s wear and replace them regularly to maintain quality. Avoid overloading your mill, as this can lead to inefficient grinding and premature wear of the beads. Remember that while zirconia silicate beads offer many benefits, they may not be suitable for all materials. Testing different sizes and compositions can yield valuable insights.

Zirconia silicate beads are gaining popularity in the grinding industry. Their high density and hardness make them ideal for various materials. In comparison with traditional grinding media, such as glass or steel balls, zirconia silicate beads stand out due to their superior wear resistance. This characteristic leads to longer-lasting performance and reduced contamination of the final product.

However, it’s essential to consider the specific requirements of each application. For softer materials, glass beads may be sufficient and more cost-effective. Steel balls, while robust, can introduce unwanted metal particles. The choice of grinding media can significantly impact the efficiency of the process.

Many users struggle with selecting the right type for their needs. Sometimes, one type may excel in one application while failing in another. Conducting tests can yield deeper insights, leading to more informed decisions. Observations reveal that the right choice often varies based on material characteristics and desired outcomes. Balancing cost and performance is always a challenge in this field.

| Grinding Media Type | Density (g/cm³) | Hardness (Mohs Scale) | Wear Rate (g/h) | Applications |

|---|---|---|---|---|

| Zirconia Silicate Beads | 6.0 | 8.5 | 0.1 | Paints, Inks, Coatings |

| Glass Beads | 2.5 | 5.5 | 0.3 | Cosmetics, Plastics |

| Steel Balls | 7.85 | 6.5 | 0.5 | Metals, Mining |

| Alumina Beads | 3.7 | 9.0 | 0.2 | Ceramics, Fuel Cells |

| Polymer Beads | 1.1 | 3.0 | 1.0 | Food Industry, Pharmaceuticals |

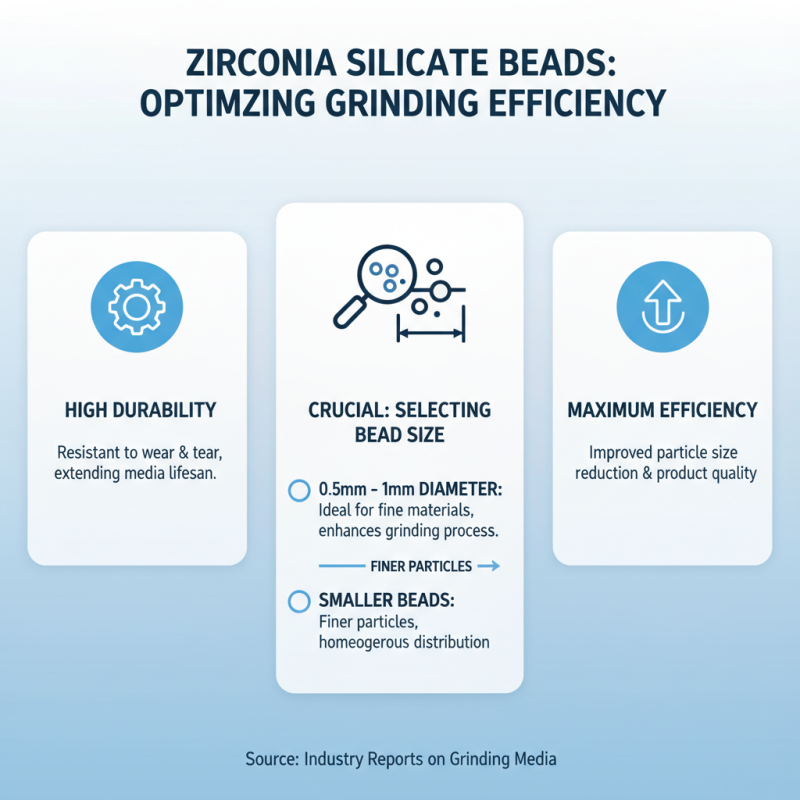

Zirconia silicate beads are popular in grinding applications due to their high durability and effectiveness. To achieve maximum efficiency, it is crucial to select the right bead size. According to industry reports, using beads with a diameter of 0.5 mm to 1 mm can significantly enhance the grinding process, especially for fine materials. Smaller beads lead to finer particle sizes and more homogeneous distributions.

Moreover, optimizing the agitation speed can also improve results. Studies indicate that maintaining the agitation speed between 1500 to 2000 RPM strikes a balance between energy consumption and grinding efficiency. Grinding media wear is another concern. Regular monitoring of bead wear can prevent excessive material loss, which can compromise performance. Some facilities report a wear rate of about 0.02 grams per hour per liter of beads.

Additionally, it’s important to address the loading ratio. Loading too many beads can lead to inefficient grinding, while too few may not utilize the equipment's potential. Striking this balance requires testing and adjustment. Operators should also be aware of the potential for inconsistent results in the grinding process, influenced by various factors such as material properties and equipment design. Familiarizing oneself with these dynamics fosters a more efficient grinding environment with zirconia silicate beads.