In the competitive landscape of modern manufacturing, optimizing operational processes is paramount for achieving higher efficiency and durability of products. One promising advancement is the use of Cerium Stabilized Zirconia Balls, a versatile material renowned for its exceptional mechanical properties and resistance to wear and corrosion. According to a 2022 report by Research and Markets, the global market for advanced ceramic materials is projected to reach $120 billion by 2027, with increasing adoption in various industries including aerospace, automotive, and biomedical sectors. This growth is largely driven by the demand for materials that can withstand extreme conditions while maintaining performance. By integrating Cerium Stabilized Zirconia Balls into manufacturing processes, companies can enhance the durability of their products and reduce maintenance costs, paving the way for sustained operational excellence.

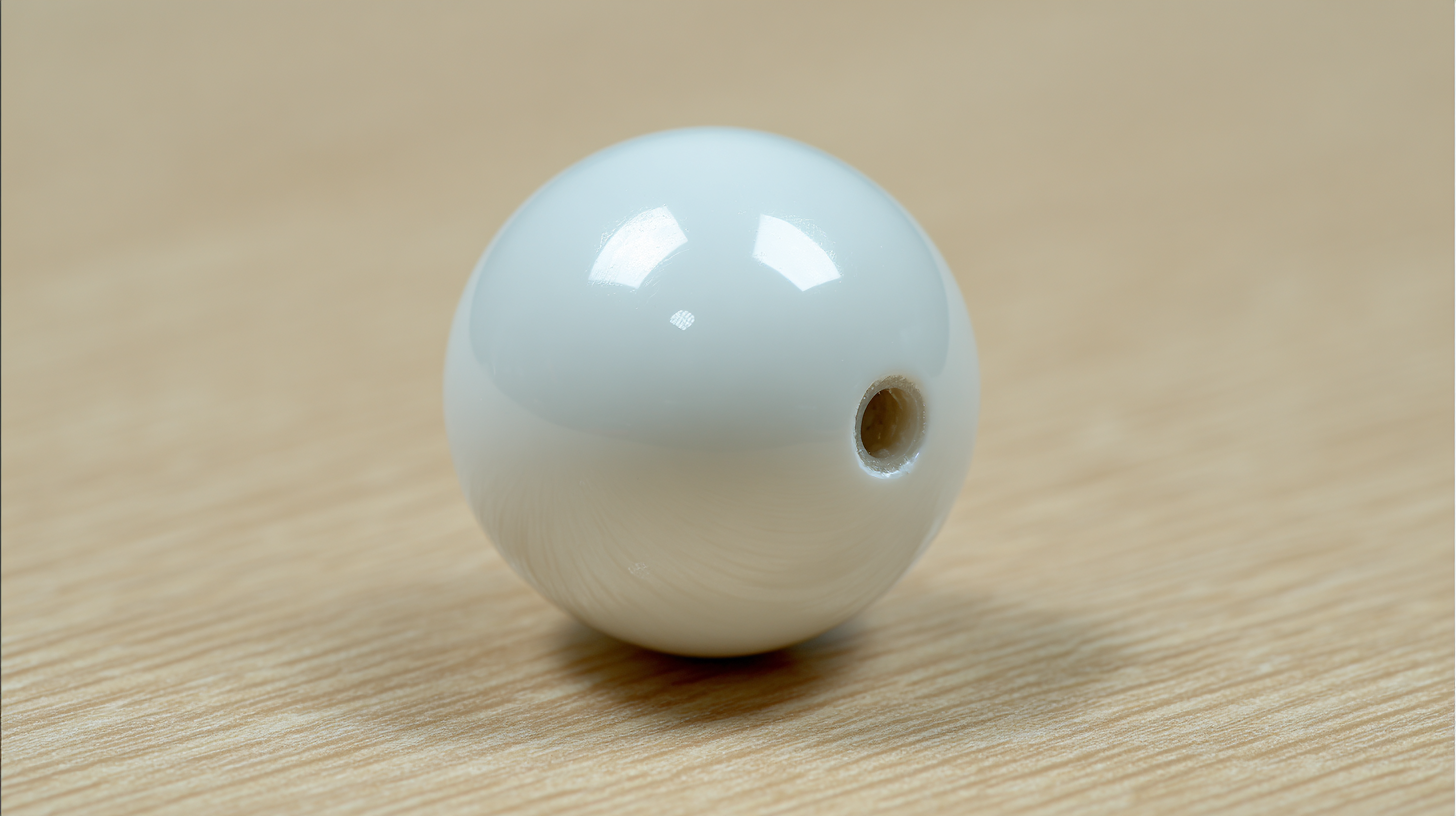

Cerium stabilized zirconia balls have gained significant attention in manufacturing due to their exceptional properties that enhance durability and performance. These spherical components are produced by adding cerium oxide to zirconia, resulting in a material that exhibits high fracture toughness and good thermal stability. This unique combination makes cerium stabilized zirconia balls ideal for applications that require resistance to wear and tear, particularly in industries such as aerospace, automotive, and medical devices.

The benefits of using cerium stabilized zirconia balls in manufacturing processes are manifold. Firstly, their high density and strength contribute to superior performance in high-load applications, reducing the frequency of maintenance and replacement. Moreover, these balls exhibit low thermal conductivity, making them suitable for environments where heat resistance is critical. This feature not only contributes to longer service life but also enhances the efficiency of the manufacturing process by minimizing downtime. By integrating cerium stabilized zirconia balls into machinery and equipment, manufacturers can achieve improved outcomes, streamline operations, and ultimately reduce costs while maintaining product quality.

When it comes to optimizing manufacturing processes, selecting the right materials is critical, and cerium stabilized zirconia balls stand out for their exceptional durability and performance. One of the key factors in choosing the appropriate cerium stabilized zirconia balls is understanding their mechanical properties. These balls offer high resistance to wear and tear, making them ideal for applications in harsh environments. Be sure to consider the specific requirements of your manufacturing process, such as temperature tolerance and load-bearing capacity, to maximize efficiency and longevity.

Another important aspect to consider is the size and shape of the zirconia balls. The optimal diameter can significantly affect the grinding efficiency and the quality of the final product. Smaller balls may be preferred for finer grinding, while larger balls can help with the reduction of larger particles. Additionally, the surface finish of the balls can influence performance; smoother surfaces reduce friction and increase durability. By carefully evaluating these factors, manufacturers can ensure they are selecting the best cerium stabilized zirconia balls for their specific applications, leading to improved outcomes in their production processes.

| Criteria | Description | Impact on Manufacturing Process |

|---|---|---|

| Material Density | Higher density improves durability and wear resistance. | Enhanced lifespan of components and reduced downtime. |

| Size Variability | Consistency in size ensures uniform performance and results. | Minimized production errors and waste reduction. |

| Thermal Stability | Ability to withstand high temperatures without deforming. | Reliable operation in high-temperature processes, preventing failures. |

| Chemical Resistance | Resistance to corrosive environments enhances lifespan. | Reduced risk of product contamination and increased safety. |

| Processing Methods | Different manufacturing methods impact the final product quality. | Optimization of manufacturing methods can lead to improved efficiency. |

| Cost-Effectiveness | Balancing quality and price to maximize ROI. | Enables budget management while maintaining quality standards. |

In the realm of advanced manufacturing, integrating cerium stabilized zirconia balls can significantly elevate the durability and efficiency of processes. According to a report from the International Journal of Advanced Manufacturing Technology, utilizing zirconia balls reduces wear and tear on machinery by up to 30%, leading to longer equipment lifespan and reduced maintenance costs. This enhanced durability is crucial for industries that rely heavily on precision, such as aerospace and automotive sectors, where failure rates can lead to catastrophic outcomes.

To effectively incorporate zirconia balls into your manufacturing workflow, consider their size and distribution within the system. A study published by the Materials Science and Engineering Journal emphasizes that optimizing the diameter and quantity of these balls can improve particle size reduction in grinding processes by as much as 25%. Additionally, implementing a systematic replacement schedule for zirconia balls can prevent performance decline caused by wear, further ensuring consistent product quality. By strategically integrating these advanced materials, manufacturers can not only enhance process reliability but also achieve greater operational efficiency.

In today's competitive manufacturing landscape, the choice of materials can significantly affect product durability and performance. Cerium stabilized zirconia balls have become increasingly popular due to their remarkable strength and wear resistance. Recent studies indicate that incorporating these zirconia balls can improve the lifespan of products by up to 30%, showcasing their capability in enhancing durability. By minimizing wear and tear in manufacturing processes, companies can reduce downtime and increase overall productivity.

To maximize the benefits of zirconia balls in manufacturing, consider the following tips: First, conduct thorough testing to evaluate the specific performance characteristics of zirconia balls under varying conditions. Second, continuously monitor the manufacturing process to ensure optimal conditions are maintained, as even slight variations can impact the effectiveness of the zirconia balls. Finally, invest in integrating high-quality zirconia balls into your production line, as subpar options can lead to reduced durability and performance.

The implications of such enhancements extend beyond raw durability. The adoption of cerium stabilized zirconia balls not only leads to longer-lasting products but also improves overall quality consistency. Therefore, manufacturers should prioritize these materials to ensure they stay ahead in delivering high-quality solutions to their customers.

Maintaining cerium stabilized zirconia balls in production is crucial for enhancing durability and optimizing manufacturing processes. These advanced materials are celebrated for their high wear resistance and thermal stability. To maximize their performance, it’s essential to implement best practices during handling and storage.

One effective tip is to regularly monitor the environmental conditions in which the zirconia balls are stored. Keeping them in a climate-controlled environment can prevent moisture absorption, which may compromise their structural integrity. Additionally, ensure that the balls are kept in a clean and dry area to minimize contamination that could lead to premature wear.