When navigating the realm of advanced materials for various industrial applications, the significance of Yttria Stabilized Zirconia Beads cannot be overstated. These innovative beads are renowned for their exceptional durability, chemical resistance, and versatility, making them a preferred choice in industries ranging from ceramics to pharmaceuticals. As projects demand increasingly precise and reliable solutions, understanding how to choose the right Yttria Stabilized Zirconia Beads becomes critical for achieving optimal results.

This guide provides a comprehensive overview for professionals seeking to incorporate Yttria Stabilized Zirconia Beads into their projects. From examining the key properties and benefits of these beads to exploring important selection criteria, the aim is to equip you with the knowledge needed to make informed decisions. Whether you are considering factors like bead size, density, or specific application requirements, a thoughtful approach to selection ensures that your project aligns with performance expectations, ultimately leading to enhanced efficiency and product quality.

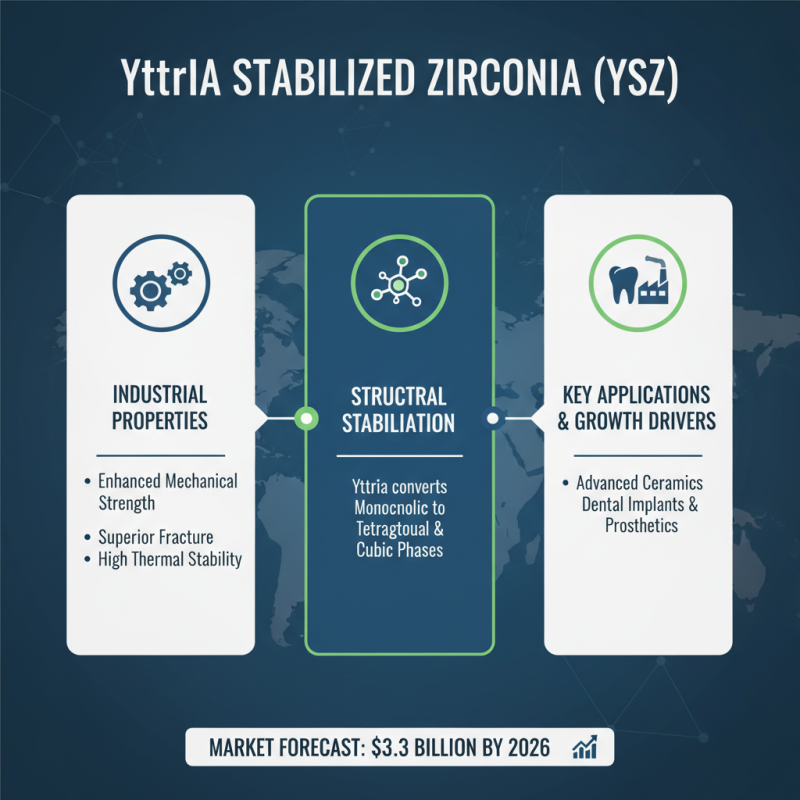

Yttria stabilized zirconia (YSZ) is a ceramic material widely recognized for its exceptional properties, making it suitable for various industrial applications. With a monoclinic structure at lower temperatures, the addition of yttria stabilizes the zirconia in its tetragonal and cubic forms, enhancing its mechanical strength, fracture toughness, and thermal stability. A report by the Global Industry Analysts projects the market for YSZ to grow significantly, reaching an estimated value of $3.3 billion by 2026, driven primarily by its use in advanced ceramics and dental applications.

The versatility of YSZ also extends to the field of catalysis, where it is used as a support material for catalysts due to its high surface area, chemical stability, and thermal resistance. Furthermore, its application in the field of solid oxide fuel cells (SOFCs) highlights its importance in energy solutions, as YSZ enables these cells to operate at high efficiencies and temperatures. According to a study published in the Journal of the American Ceramic Society, YSZ exhibits ionic conductivity that is vital for facilitating the movement of oxygen ions in SOFCs, thus playing a crucial role in the development of sustainable energy sources. Understanding these properties and applications is essential for effectively choosing YSZ beads for specific projects, ensuring optimal performance and efficiency.

When selecting yttria stabilized zirconia beads for your projects, it is crucial to consider several key factors that can significantly impact performance and efficiency. One essential aspect is the bead's size distribution. Research indicates that a narrower size distribution can lead to enhanced grinding efficiency and reduced processing times. A study by the Industrial Ceramics Association revealed that using beads with a size distribution of 0.5 to 1.0 mm can improve particle size reduction by over 30%, leading to better dispersion quality in a variety of applications.

Another important factor is the bead density and hardness, which directly correlate to wear resistance and longevity during grinding processes. A report from the Global Ceramics Market Analysis noted that yttria stabilized zirconia beads exhibit high density, typically around 6.0 g/cm³, which contributes to their durability. This characteristic is particularly significant for industries that operate under high-stress conditions, as it not only extends the lifespan of the beads but also maintains consistent output quality. Additionally, evaluating the chemical resistance of the zirconia beads is essential, especially for applications involving corrosive materials, to prevent contamination and ensure the integrity of the final product.

When it comes to selecting beads for various industrial and research projects, yttria stabilized zirconia (YSZ) stands out due to its superior properties compared to other types of zirconia. YSZ beads boast a higher fracture toughness and thermal stability, making them ideal for high-energy milling and advanced ceramic applications. According to a report by the International Journal of Advanced Manufacturing Technology, YSZ exhibits a hardness of around 1200 HV, significantly outperforming both partially stabilized and fully stabilized zirconia beads. This is crucial for processes requiring durability under extreme conditions, such as in the production of ceramic composites or in the pharmaceutical industry.

In contrast, other forms of zirconia may be more suitable for less demanding applications. For instance, partially stabilized zirconia tends to be more cost-effective but compromises on strength and wear resistance. This trade-off is essential when determining the right material for specific applications. Furthermore, research from the Journal of Materials Science indicates that while regular zirconia might suffice for less rigorous projects, YSZ is ultimately more reliable for those requiring long-term performance and less frequent replacement.

Tips: When selecting the appropriate zirconia beads, consider the specific requirements of your project, including the operating environment and cost constraints. If durability and precision are paramount, investing in YSZ beads is advisable, while for less critical applications, exploring other zirconia types may yield satisfactory results at a lower price point. Always evaluate your needs against the technical specifications of the materials at hand to make an informed decision.

| Property | Yttria Stabilized Zirconia (YSZ) | Ceria Stabilized Zirconia (CSZ) | Magnesia Stabilized Zirconia (MSZ) | Alumina Toughened Zirconia (ATZ) |

|---|---|---|---|---|

| Density (g/cm³) | 6.05 | 6.10 | 6.20 | 5.80 |

| Hardness (HV) | 1200 | 1150 | 1080 | 1250 |

| Fracture Toughness (MPa·m1/2) | 9.5 | 8.0 | 6.5 | 10.0 |

| Thermal Conductivity (W/m·K) | 2.0 | 1.8 | 1.6 | 2.2 |

| Applications | Ceramic grinding, dental | Electronic components | High-temperature applications | Manufacturing tools |

When sourcing yttria stabilized zirconia beads for your projects, quality assurance should be a paramount consideration. Start by evaluating potential suppliers based on their manufacturing processes and adherence to industry standards. It’s essential to inquire about the materials used in production and confirm that they meet the specifications for purity and consistency. Look for certifications such as ISO 9001, which can provide assurance about the supplier's commitment to quality management systems.

Additionally, conducting a thorough assessment of the bead’s performance characteristics is crucial. Request samples to evaluate attributes such as hardness, wear resistance, and particle size distribution. Testing these beads in real-world applications can provide insights into their durability and effectiveness. Establishing a clear communication channel with suppliers can also facilitate quality checks and guarantee that any issues are promptly addressed, ensuring that your projects benefit from reliable and high-performing materials.

When selecting yttria stabilized zirconia beads for your projects, understanding their performance attributes is crucial. Recent studies have shown that these beads offer exceptional durability and high resistance to wear, making them ideal for applications involving grinding and milling. For instance, a report from the International Journal of Advanced Manufacturing Technology indicated that zirconia beads can enhance grinding efficiency by 25% compared to traditional ceramic media. This means users can achieve finer particle sizes with reduced energy consumption, ultimately leading to cost savings and improved product quality.

To optimize the performance of zirconia beads, proper selection based on your specific application is essential. Factors such as bead size, density, and processing conditions must align with the materials being processed. For example, using smaller beads can enhance the homogenization of materials in high-energy ball mills, while larger beads are more effective in breaking down harder materials. Additionally, maintaining an appropriate viscosity of the slurry can significantly impact the bead's movement and efficiency. A study published in the Journal of Materials Science found that adjusting the viscosity could improve the dispersion and prevent premature wear of the beads, which underscores the importance of fine-tuning your operational parameters.

This chart illustrates the performance comparison of different Yttria Stabilized Zirconia (YSZ) beads based on their size and density, which are critical factors in optimizing their application in various projects.