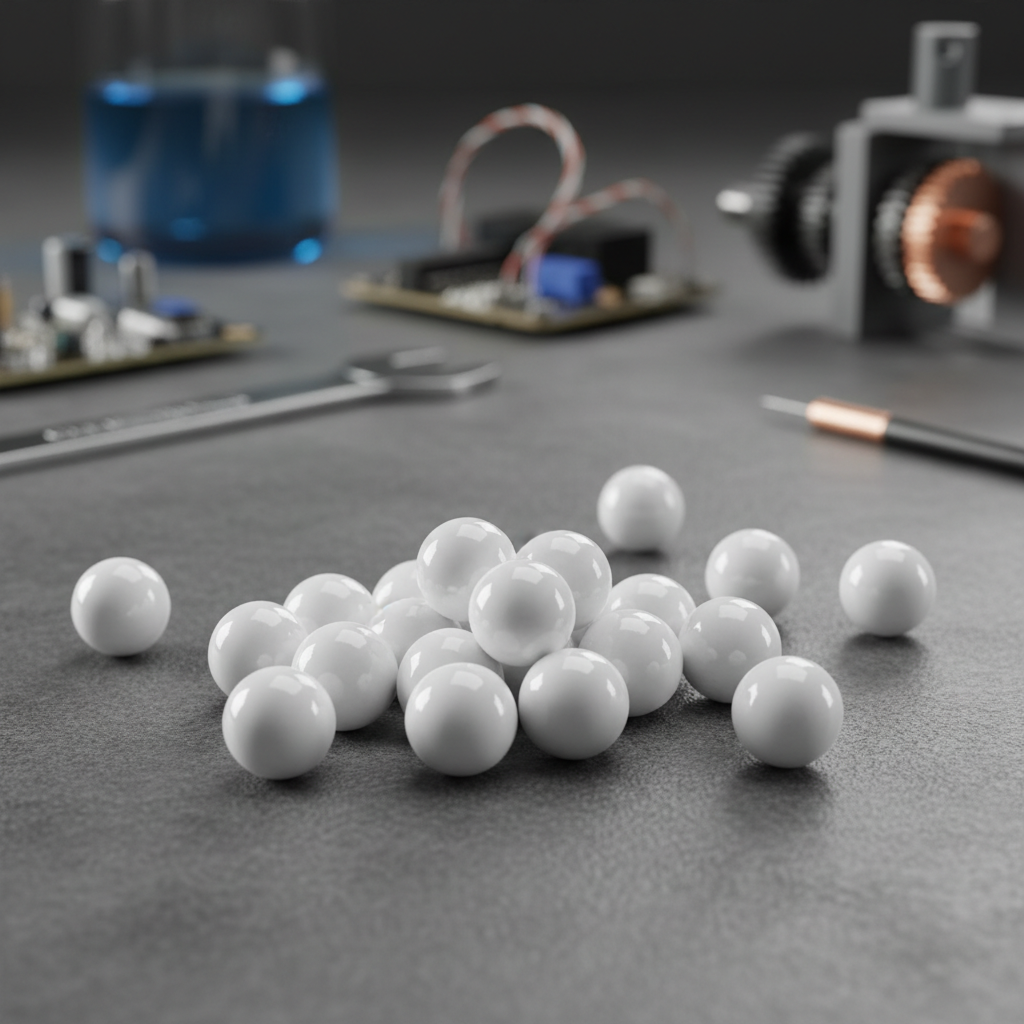

When embarking on projects that demand durability and precision, the choice of materials becomes crucial. Among the various options available, the 6mm Zirconia Ball stands out as a superior choice, offering not only exceptional strength and wear resistance but also a remarkable aesthetic appeal. This guide presents ten essential tips for effectively utilizing 6mm Zirconia Balls in your projects, ensuring optimal performance and longevity.

Understanding the unique properties of 6mm Zirconia Balls is key to harnessing their potential. Whether for industrial applications, crafting, or DIY endeavors, these balls can enhance your project's overall functionality and design. Our tips will cover various aspects, from selecting the right type of 6mm Zirconia Ball for specific tasks to integrating them seamlessly into your designs. Embracing these insights will empower you to maximize the benefits of this remarkable material in your work.

When considering the utilization of 6mm zirconia balls in project applications, it's essential to understand the unique advantages these materials offer. Zirconia balls are renowned for their exceptional durability and resistance to wear, making them ideal for projects that require high performance and longevity. Their smooth surface facilitates low friction, which can enhance efficiency in mechanical systems. Additionally, zirconia's chemical stability allows it to withstand harsh environments, ensuring that it maintains its integrity over time, even in challenging conditions.

Moreover, the lightweight nature of 6mm zirconia balls can significantly improve the dynamics of systems where weight is a critical factor. This is particularly beneficial in applications such as robotics and precision engineering where reduced mass leads to faster, more agile movements. Their versatility does not stop there; these zirconia balls can also be used in aesthetic designs, providing a sophisticated finish to various projects. By understanding these advantages, one can effectively leverage 6mm zirconia balls to optimize both functionality and design in their work.

When selecting 6mm zirconia balls for your projects, it's crucial to consider several key factors that can significantly impact performance and longevity. Firstly, the purity of the zirconia material is paramount; high-purity zirconia (over 99.5% pure) boasts exceptional wear resistance and toughness, making it ideal for applications in industrial settings. Reports indicate that using higher-purity materials can increase the lifespan of components by up to 30%, reducing replacement costs and enhancing overall efficiency.

Another important consideration is the intended application. Different manufacturing processes or environments may require specific properties such as hardness, corrosion resistance, or thermal stability. For instance, in high-temperature applications, selecting zirconia that maintains structural integrity at temperatures above 1000°C is essential.

Tip: Always verify the supplier’s certifications and performance data to ensure the zirconia balls meet the required specifications for your project. Furthermore, conducting a thorough review of the compatibility of the zirconia balls with other materials in your setup can prevent possible breakdowns or failures. These considerations will help you make an informed choice that optimizes your project's efficiency and reliability.

When incorporating 6mm zirconia balls into your designs, understanding their properties is crucial. These ceramic balls are known for their exceptional strength and wear resistance, making them ideal for various applications. Start by considering the overall design of your project; the placement and function of the zirconia balls can greatly influence the aesthetic and durability of your final product.

One essential tip is to ensure a secure fit when integrating the zirconia balls. Depending on your design, utilizing the right adhesives or physical anchoring can enhance the stability of your assembly. Additionally, pay attention to the surface finish of both the zirconia balls and the surrounding components. A smooth finish can help reduce friction and wear, particularly in moving parts, which is vital for maintaining the integrity of your design over time.

Another best practice is to experiment with different arrangements of the zirconia balls to achieve the desired visual effect and functionality. A well-thought-out configuration can highlight their glossy surface and create intriguing patterns. Furthermore, consider varying the spacing between the balls to balance both aesthetic appeal and performance, ensuring they serve their purpose effectively while enhancing your project's overall look.

| Tip Number | Best Practice | Description |

|---|---|---|

| 1 | Select Quality Material | Ensure zirconia balls are made from high-quality zirconium oxide for durability. |

| 2 | Maintain Cleanliness | Keep balls clean to prevent contamination in sensitive applications. |

| 3 | Use Appropriate Lubrication | Apply suitable lubricants to enhance mobility in mechanical assemblies. |

| 4 | Check Size Consistency | Ensure all balls measure exactly 6mm for seamless integration. |

| 5 | Consider Weight Distribution | Design projects with balanced weight for improved stability. |

| 6 | Evaluate Thermal Properties | Use zirconia balls that can withstand high temperatures, if necessary. |

| 7 | Plan for Assembly | Design assembly processes to accommodate the use of zirconia balls. |

| 8 | Test Performance | Conduct thorough tests to evaluate performance in your designs. |

| 9 | Explore Different Applications | Investigate various uses, such as in bearings or decorative designs. |

| 10 | Seek Expert Advice | Consult professionals for specific challenges and advanced techniques. |

To ensure the longevity of 6mm zirconia balls in your projects, proper care and maintenance are critical. These durable components are often utilized in various applications, from dental restorations to jewelry. To maintain their integrity, it’s essential to clean them regularly using a soft cloth or a non-abrasive cleaner designed for ceramics. Avoid exposing zirconia balls to harsh chemicals or extreme temperatures, which can lead to damage or discoloration.

Additionally, storing zirconia balls in a safe and dry environment will help prevent any accidental scratches or impacts that could compromise their quality. When using them in projects, ensure they are handled gently throughout the process. Implementing these care tips will not only enhance the performance of the zirconia balls but also extend their lifespan, making them a reliable choice for your various needs.

6mm zirconia balls have emerged as versatile components across various industries, taking advantage of their unique properties such as high strength, hardness, and resistance to wear and corrosion. In precision engineering, these balls are essential in enhancing the performance and longevity of bearings and valves. Their smooth surface reduces friction, enabling machinery to operate more efficiently, which is crucial in manufacturing sectors where precision is paramount.

Furthermore, the application of 6mm zirconia balls in the field of biomedical engineering is gaining traction. Their biocompatibility makes them ideal candidates for dental implants and prosthetics, where reliability and durability are essential. Beyond mechanical uses, they are also being explored for innovative applications in cosmetics and beauty products, where they can serve as exfoliating agents or as part of formulations that enhance texture and stability. The multifaceted nature of these zirconia balls highlights their growing significance and adaptability in solving complex challenges across different industries.