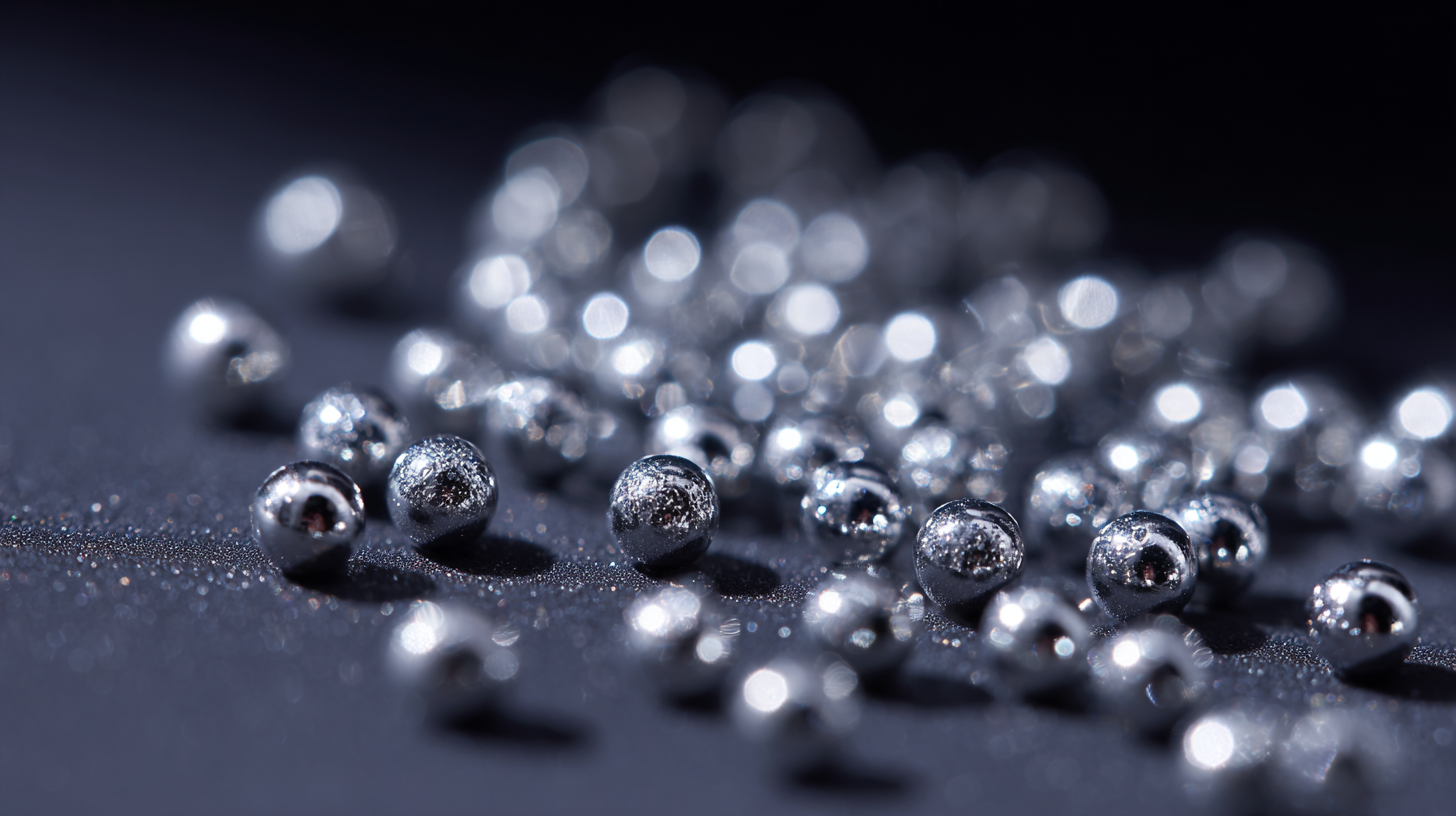

When it comes to selecting the ideal 95% Zirconia Bead for your specific requirements, there are several essential considerations to keep in mind. Whether you are using these beads for precision milling, polishing, or as a key component in your production process, understanding their unique properties and applications is crucial. The high durability and wear resistance of 95% Zirconia Beads make them a popular choice across various industries, from ceramics to pharmaceuticals. However, not all zirconia beads are created equal; factors such as size, shape, and surface finish can significantly impact performance. In this comprehensive guide, we'll explore seven essential tips to help you make an informed decision and ensure you choose the best 95% Zirconia Bead tailored to your needs, enhancing efficiency and achieving optimal results in your projects.

When choosing the best 95 percent zirconia beads, it's essential to understand the varying grades available in the market. Zirconia beads are produced through a sophisticated process that influences their hardness, wear resistance, and overall performance. According to a recent report by the Ceramic Industry Journal, high-quality 95 percent zirconia beads typically exhibit a Vickers hardness of around 1200 HV, making them significantly tougher than traditional ceramic beads. This hardness level is crucial for applications requiring durability, such as in the grinding and milling of materials.

Different grades of zirconia beads can have varying levels of purity and structural integrity, which directly impact their usage. For example, while standard 95 percent zirconia beads may be adequate for general use, premium grades often contain additives that enhance their properties, resulting in superior performance in high-energy processes. The Advanced Materials Research publication highlights that these premium grades can reduce wear rates by up to 30% compared to their lower-grade counterparts. This data indicates that investment in higher-grade zirconia beads could lead to both operational efficiency and reduced costs in the long run.

When selecting the best 95 percent zirconia bead, the evaluation of particle size and shape is critical for achieving optimal performance in your applications. The particle size plays a significant role in the milling process, influencing the surface area and the number of contact points. Smaller beads can provide finer grinding, while larger beads can offer better impact and efficiency in more robust applications.

Tip 1: Assess your specific grinding needs. If you require finer particle sizes in your product, smaller zirconia beads are your best choice. Conversely, for reductions involving more robust materials, a larger bead may be more effective.

Additionally, the shape of the beads can affect their performance. Spherical beads generally provide a more uniform grinding action, whereas irregularly shaped beads can increase the surface area and provide enhanced shear forces.

Tip 2: Consider the shape that will best suit your milling equipment. If you’re using a high-energy mill, spherical beads might be ideal. However, if your equipment allows for more varied motion, you may benefit from using a mix of geometries. Effective evaluation of these factors will ensure you choose zirconia beads that meet your performance requirements.

When selecting 95 percent zirconia beads for various applications, assessing their durability and wear resistance is paramount. These properties determine how well the beads will perform under stress, especially in high-impact environments. Zirconia beads are known for their hardness, but variations in their manufacturing process can affect their final performance. Look for beads that have undergone rigorous testing for durability and wear resistance to ensure you choose the best option for your specific needs.

Tip 1: Always check for the hardness rating of the zirconia beads. A higher hardness rating indicates that the beads will be more resistant to abrasions and will last longer in applications such as grinding or polishing.

Tip 2: Consider the bead's shape and size. Uniform sizing contributes to better performance in applications like milling, as irregular shapes can lead to uneven wear and reduced efficiency.

Additionally, it's vital to evaluate the beads' resistance to high temperatures and corrosive environments if applicable. This ensures that your investment not only meets current needs but also withstands future challenges. Overall, careful consideration of these factors will significantly enhance your operational effectiveness.

When it comes to selecting the right supplier for 95 percent zirconia beads, quality and consistency should be your primary concerns. According to a report by Research and Markets, the global zirconia market is expected to reach approximately $2.5 billion by 2025, highlighting the increasing demand for high-quality zirconia products. This booming market emphasizes the importance of sourcing from reputable suppliers who adhere to strict quality control measures to ensure the beads meet industry standards.

One key factor to consider is the supplier's certifications and manufacturing processes. ISO 9001 certification, for instance, indicates that the supplier follows internationally recognized quality management systems. Furthermore, suppliers who utilize advanced technologies in their production processes can often provide zirconia beads with superior performance characteristics, such as enhanced durability and reduced wear, which are crucial for applications in various industries like dentistry and ceramics. By prioritizing these aspects, you can ensure that the zirconia beads you choose will deliver consistent quality and functionality, ultimately supporting the success of your projects.

When selecting 95 percent zirconia beads, it's crucial to weigh the price against performance to ensure you're making the best investment for your needs. While it may be tempting to opt for the cheapest option available, lower prices can often correlate with reduced durability and effectiveness. Higher-quality beads tend to offer superior wear resistance and a longer lifespan, which can ultimately save you money in the long run by minimizing replacement costs.

Performance metrics such as hardness, density, and grinding efficiency are essential considerations. When evaluating zirconia beads, it’s advisable to seek out detailed specifications and performance reviews. A good balance of price and performance can be achieved by comparing different brands and their offerings to find a product that meets your operational requirements without overshooting your budget. Investing in slightly more expensive, high-performance beads can enhance productivity and yield better results, making them a worthwhile consideration for both hobbyists and professionals.

This chart compares the price and performance ratings of various 95 percent zirconia beads. It helps in visualizing the trade-off between cost and quality for informed decision-making.