The use of Zro2 Ceramic Ball 65% in various industrial applications has been gaining momentum due to its superior properties and performance enhancement capabilities. According to a market analysis conducted by Grand View Research, the global ceramics market is projected to reach approximately USD 320 billion by 2025, with ceramics such as Zro2 being a significant contributor to this growth due to their high strength, thermal stability, and wear resistance. These characteristics make Zro2 Ceramic Ball 65% particularly suitable for applications in aerospace, automotive, and medical devices, where precision and durability are paramount. As industries continually seek methods to improve operational efficiency while reducing maintenance costs, integrating Zro2 Ceramic Ball 65% into existing systems presents a viable solution that not only enhances performance but also extends the lifespan of machinery. This comprehensive guide will delve into the benefits, applications, and best practices for utilizing Zro2 Ceramic Ball 65% effectively across various sectors.

ZrO2 ceramic balls, composed of approximately 65% zirconium dioxide, are renowned for their exceptional mechanical properties and chemical resistance. These unique characteristics make them an ideal choice in various industries, including aerospace, automotive, and biomedical applications. According to a recent industry report by Grand View Research, the global market for ceramic materials is expected to reach $330 billion by 2026, driven in part by the demand for high-performance components like ZrO2 ceramic balls.

One of the standout properties of ZrO2 ceramic balls is their high fracture toughness, which is about 20% higher than traditional alumina ceramics. This toughness ensures that components can withstand significant stress without compromising their integrity, making them suitable for high-load applications. Additionally, ZrO2 exhibits excellent wear resistance, with studies indicating a wear rate reduction of up to 50% when compared to steel alternatives in certain environments. These features not only enhance the longevity of the products but also reduce maintenance costs, providing a compelling reason for industries to adopt ZrO2 ceramic balls in their manufacturing processes.

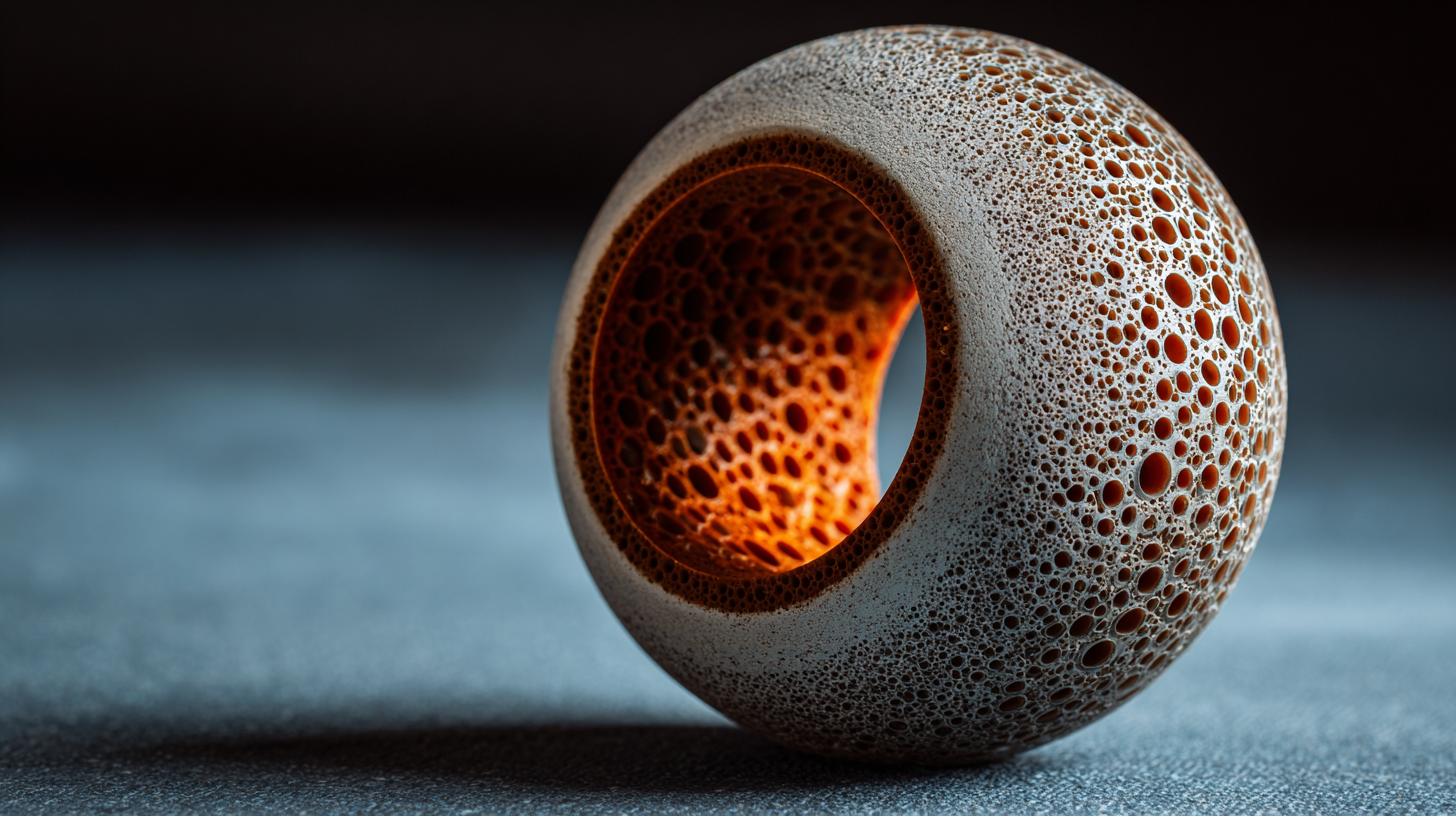

This chart illustrates the comparative performance metrics of ZrO2 ceramic balls with 65% zirconia content across different applications. The data points reflect their effectiveness in various parameters: wear resistance, thermal stability, and load capacity.

ZrO2 ceramic balls, composed of zirconium dioxide, are increasingly favored across various industries due to their remarkable properties. One of the primary advantages of ZrO2 ceramic balls is their superior hardness, which allows them to withstand wear and tear even in demanding environments. This durability translates to enhanced performance in applications such as grinding, milling, and bearing operations, where the integrity of components is crucial for efficiency and longevity.

Additionally, ZrO2 balls exhibit exceptional resistance to corrosion and high temperatures. This makes them ideal for use in chemical processing and aerospace applications, where exposure to harsh conditions is common. Their low friction coefficient further contributes to improved energy efficiency and reduced maintenance costs. By integrating ZrO2 ceramic balls into machinery and equipment, manufacturers can achieve higher operational performance and reliability, ultimately leading to increased productivity and reduced downtime.

When it comes to enhancing performance in various applications, implementing ZrO2 ceramic balls can be a game-changer. One of the best practices for utilizing these ceramic balls is to ensure proper selection based on the specific operating environment. It is essential to consider factors such as load, speed, and temperature when choosing the right ZrO2 ceramic ball to guarantee optimal performance and longevity.

Another crucial aspect is to maintain precise lubrication in systems using ZrO2 ceramic balls. Unlike traditional metal balls, ceramic balls require careful consideration of the lubrication type to reduce wear and friction. Using appropriate lubricants that can withstand high temperatures while minimizing chemical reactions will significantly enhance the durability of the ceramic ball system. Additionally, regular inspection and maintenance of the system can help identify potential issues before they escalate, ensuring continued efficiency and performance.

| Application | Zro2 Ball Size (mm) | Performance Improvement (%) | Operating Temperature (°C) | Durability (Cycles) |

|---|---|---|---|---|

| Bearing Systems | 3.0 | 25 | 150 | 1,000,000 |

| Medical Devices | 1.5 | 30 | 60 | 500,000 |

| Aerospace Components | 5.0 | 20 | 350 | 750,000 |

| Automotive Parts | 2.0 | 22 | 130 | 600,000 |

| Industrial Tools | 4.0 | 28 | 180 | 850,000 |

Zirconia (ZrO2) ceramic balls have gained significant attention as alternatives to traditional materials in various applications, including biomedical implants. A comparative analysis of zirconia and alternative materials, such as alumina and titanium, highlights the advantages of zirconia in wear resistance and mechanical strength. Particularly in the realm of dental and orthopedic applications, zirconia has shown promising results in terms of longevity and biocompatibility, making it an attractive option for manufacturers seeking high-performance solutions.

Tips: When considering materials for implant applications, evaluate the wear characteristics and biocompatibility of zirconia versus alternatives. Conducting thorough mechanical testing can help in selecting the most appropriate material for specific clinical needs.

Recent studies, including those investigating the bone-implant interface, suggest that zirconia implants may provide superior outcomes compared to titanium, especially in terms of integration and fracture resistance. Additionally, the advancements in manufacturing techniques, such as CAD/CAM applications, are enhancing the ability to produce accurate and reliable zirconia components for various medical uses.

Tips: Always stay updated on the latest manufacturing methods to ensure the best performance of ceramic materials. Understanding the properties of different ceramics can significantly affect the success of prosthetic solutions in terms of durability and patient outcomes.

To ensure the longevity and optimal performance of Zro2 ceramic balls, regular maintenance is crucial. Start with routine inspections to identify any wear or damage. Keeping the ceramic balls free from contaminants is essential; therefore, clean them regularly using a soft cloth and appropriate cleaning agents that do not scratch the surface. Make sure to avoid aggressive solvents and scrubbing tools that could harm the material's integrity.

Additionally, consider the operating environment where the Zro2 ceramic balls are used. Limiting exposure to extreme temperatures and corrosive substances can significantly enhance their lifespan. Proper lubrication is also key in minimizing friction during operation. Utilize lubricants that are compatible with Zro2 materials to maintain effectiveness.

Finally, maintaining a consistent operating speed and load can prevent unnecessary stress on the ceramic balls, thus ensuring they remain in peak condition for an extended period. Following these maintenance tips will lead to improved performance and reliability of Zro2 ceramic balls in various applications.