Choosing the right Zirconia Ball Media is crucial for achieving optimal results in various applications. According to a recent market report by Smith & Associates, the demand for high-quality Zirconia media has increased by 30% over the past year. This rise signals a growing recognition of its advantages in grinding and dispersion.

Industry expert Dr. Elizabeth Warner states, “The right Zirconia Ball Media can significantly enhance the efficiency of your process.” This insight highlights the importance of selecting the appropriate size and composition tailored to specific needs. Different applications might require varying properties, such as hardness and wear resistance, which can make the selection process challenging.

However, overlooking these factors can lead to inefficiencies and increased operational costs. Many users struggle to identify their exact requirements. Assessing the type of material being processed and its compatibility with Zirconia media is essential. Exploring various options can seem daunting, yet it is pivotal for maximizing productivity.

Zirconia ball media is a popular choice in grinding and milling. Understanding its properties can help you make better choices. It's durable and resists wear well, making it ideal for various applications. The density of zirconia balls affects the grinding efficiency. Higher density means better grinding performance.

When selecting zirconia ball media, consider the size and shape. Smaller balls can lead to finer material but may come with longer processing times. Larger balls grind faster but may leave larger particle sizes. The shape also plays a role; round balls are common, but other shapes are available. Experimenting with different options can yield surprising results.

Be mindful that not all zirconia media is the same. Different formulations exist, each suited for specific tasks. Understanding these variations can be challenging. You may find a product that works well in theory but fails in practice. Reflecting on previous choices can lead to better outcomes. Test your media under real conditions for the best insight.

When selecting zirconia ball media, understanding your specific application is crucial. Different industries have distinct requirements. For example, in the pharmaceutical sector, the media must achieve a high level of purity. Contaminants can lead to product rejection and increased costs. In contrast, ceramic processing may require stronger, more durable balls to withstand harsh conditions.

According to a recent industry report, zirconia balls can improve grinding efficiency by up to 30% compared to traditional media. This significant increase highlights the need to match the media's properties with application demands. Factors such as media size, density, and hardness play a vital role in achieving optimal results. A mismatch can lead to inefficiencies and higher production times.

Additionally, the composition of zirconia is a key consideration. Certain applications may require blended materials to enhance specific characteristics. This customization process can be complex and time-consuming. Some manufacturers struggle with achieving the right balance between cost and performance. It's vital to analyze both short-term and long-term impacts of your choice. Recognizing these nuances can significantly influence your final decision.

| Application | Zirconia Ball Size (mm) | Density (g/cm3) | Hardness (HV) | Typical Use |

|---|---|---|---|---|

| Ceramic Processing | 1.0 - 2.0 | 6.0 | 1200 | Milling of ceramic materials |

| Paint and Coatings | 0.5 - 1.5 | 5.8 | 1100 | Dispersing pigments |

| Pharmaceuticals | 0.2 - 1.0 | 6.1 | 1300 | Size reduction of drugs |

| Metalworking | 2.0 - 8.0 | 6.2 | 1400 | Grinding of metal materials |

| Ink Production | 0.5 - 1.0 | 5.9 | 1150 | Grinding and dispersing inks |

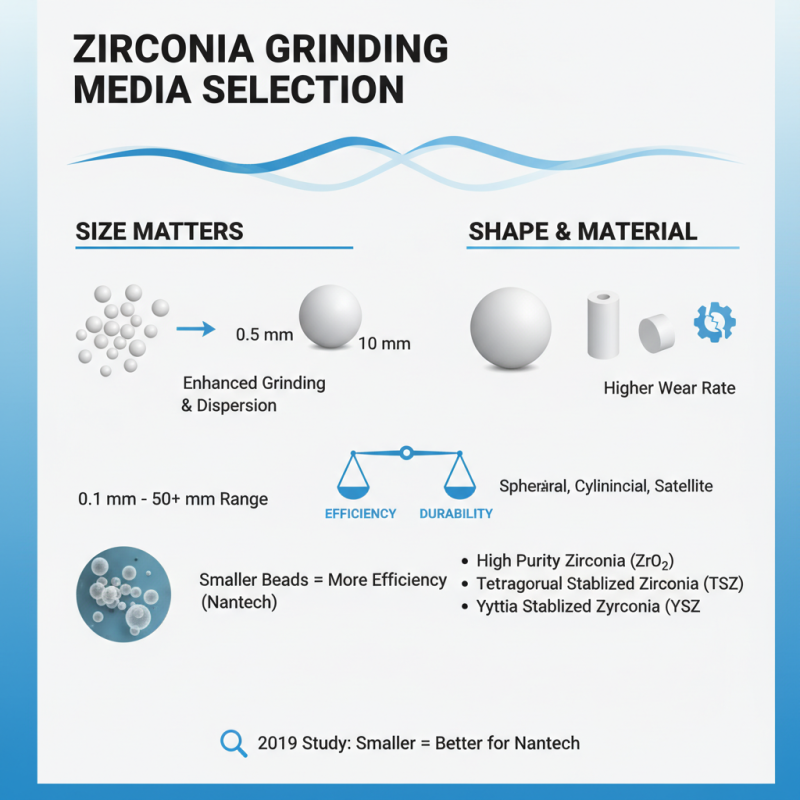

When selecting zirconia ball media, size and shape are critical. The diameter of these balls can range from 0.1 mm to over 50 mm. A 2019 study noted that smaller beads are more effective in grinding and dispersing materials, particularly in nanotechnology applications. For instance, 0.5 mm balls show a significant increase in efficiency compared to larger options. However, using smaller beads may lead to higher wear rates, necessitating a balance in choice.

Shape also plays a vital role. Most zirconia balls are spherical, but variations exist. Some manufacturers produce oval or irregular shapes. Research indicates that irregular shapes can lead to better flow dynamics within mills. This can enhance the grinding process. However, irregular shapes may also lead to inconsistent results. These choices should be weighed carefully based on the specific application.

The density of zirconia media further complicates decision-making. Higher density balls offer increased grinding efficiency. A report from an industry expert noted that density differences can affect wear rates and processing outcomes. Cement materials, for instance, may require dense balls. Yet, balancing density with the potential for excessive wear introduces a challenge. Every choice made demands thoughtful consideration for optimal results.

When selecting zirconia ball media, cost-efficiency and longevity are vital. A recent industry report suggests that zirconia media can last up to five times longer than traditional steel balls. This longevity is crucial for applications demanding consistent performance, like in grinding and milling processes.

However, the initial investment in high-quality zirconia balls can be daunting. Prices vary significantly, with some variants costing up to 50% more than standard options. Despite the upfront costs, the extended lifespan often compensates for this, leading to reduced replacement frequency. An analysis revealed that companies switching to premium zirconia media reported a 30% decrease in downtime related to media replacement.

Yet, the choice is not straightforward. Some users have experienced issues with breakage under extreme conditions. Variants with higher density are more durable but come with increased costs. It's essential to balance performance against budget constraints carefully. Testing different media types can help identify the most suitable option for specific applications. Ultimately, making an informed decision requires assessing both the long-term benefits and immediate financial implications.

Choosing the right zirconia ball media is not straightforward. There are many performance metrics to consider. The density, size, and shape of the balls all play significant roles. For instance, denser media may provide better grinding efficiency. However, they can also wear out equipment faster. This is an essential trade-off that needs careful thought.

Another important metric is the hardness of the zirconia. Harder balls usually result in finer particle sizes. Yet, if the hardness is too high, it can cause excessive wear on machinery. Sizing is equally crucial. Smaller balls can reach tighter spaces. On the other hand, larger balls might provide faster processing times but can struggle with fine materials.

It’s essential to balance these factors. Many users experiment with different options before finding the ideal match. This process requires reflection and adjustment. Ultimately, the right choice can significantly enhance performance, but it may take time to discover what truly works best for your specific applications.