Zirconia Ball Media has become a pivotal component in the precision grinding and polishing industry, significantly enhancing the efficiency and quality of material processing. According to a recent report by Market Research Future, the global market for ceramic balls, including Zirconia Ball Media, is projected to reach USD 1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4% from 2020. This remarkable growth is attributed to the increasing demand for high-performance materials across various sectors, including automotive, aerospace, and electronics.

Industry expert Dr. Emily Tran, a leading authority on advanced grinding technologies, emphasizes the benefits of Zirconia Ball Media, stating, "The exceptional hardness and durability of Zirconia balls make them ideal for achieving superior surface finishes and extended lifespan in both wet and dry grinding applications." This sentiment underscores the significance of using high-quality media like Zirconia in optimizing production processes while minimizing waste and operational costs. As industries continue to evolve and prioritize precision, adopting Zirconia Ball Media for grinding and polishing tasks is not merely beneficial; it is essential for maintaining a competitive edge in today’s market.

Zirconia ball media has become an essential choice for various grinding and polishing applications due to its superior properties. One of the foremost advantages is its exceptional hardness—Zirconia has a hardness rating of approximately 1200 HV (Vickers hardness), making it much harder than traditional materials like steel or ceramic. This increased hardness allows for more efficient and faster grinding, leading to reduced processing times and lower energy consumption, which is a crucial aspect for industries aiming to maximize productivity.

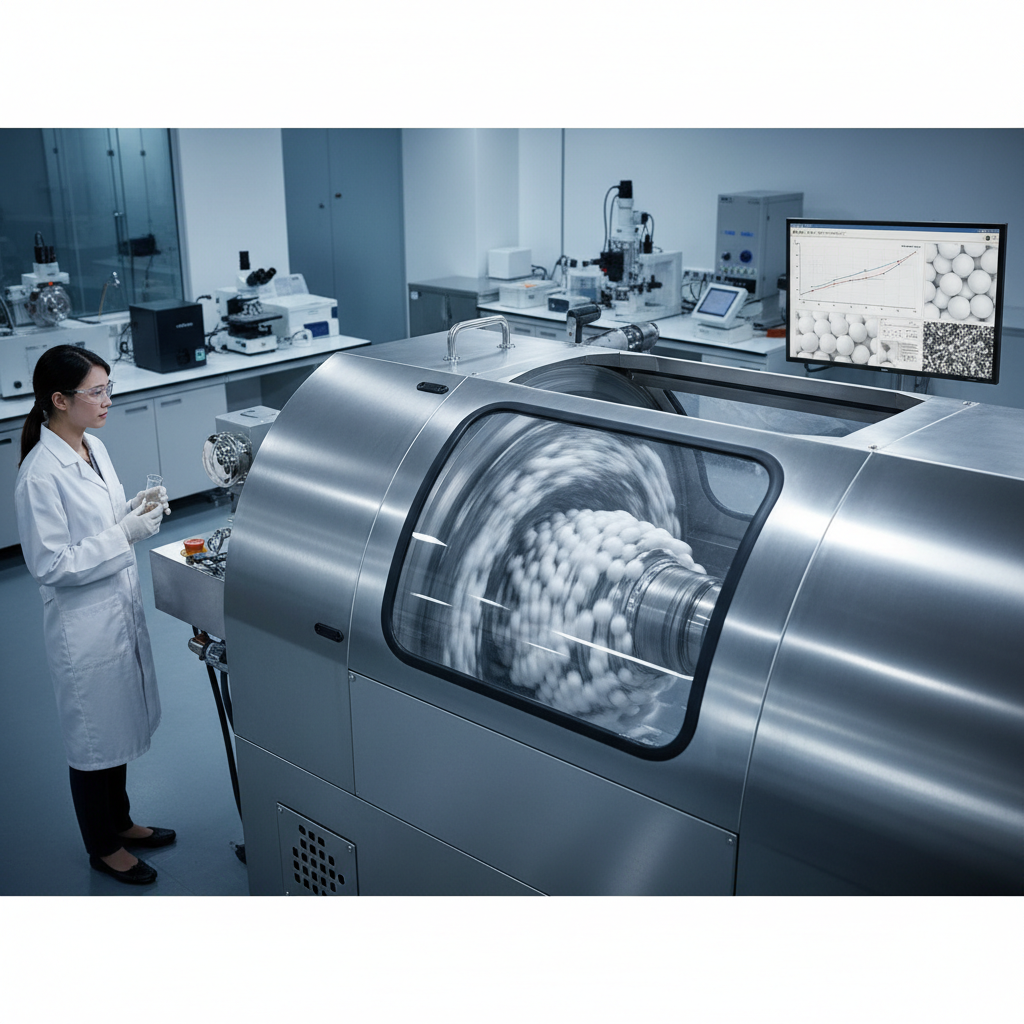

Furthermore, zirconia ball media exhibits excellent wear resistance and minimized breakage rates. Studies have shown that the use of zirconia media can lower media loss by up to 50% compared to other materials, significantly driving down costs over time. Additionally, the inert nature of zirconia ensures that contamination is kept to a minimum, preserving the integrity of the materials being processed. According to a report by the International Journal of Advance Manufacturing Technology, using zirconia media can result in a 30% improvement in the quality of the final product, making it a preferred choice for precision applications in industries such as electronics, ceramics, and pharmaceuticals.

| Advantage | Description | Applications | Durability |

|---|---|---|---|

| High Density | Provides superior grinding efficiency and time savings. | Ceramic materials, Paints, and Coatings. | Excellent wear resistance for prolonged use. |

| Low Contamination | Minimizes particle contamination, ensuring product purity. | Pharmaceuticals, Cosmetics. | Not prone to chemical reactions. |

| Versatile Size Options | Available in various sizes to suit different applications. | Food processing, Ink manufacturing. | Durable against breaks and chips. |

| High Resilience | Withstands high-impact forces during grinding processes. | Metals processing, Mining. | Stays intact under harsh conditions. |

| Eco-friendly | Does not contain harmful materials, safer for environment. | Recycling processes, Clean technologies. | Longer life cycle, reducing waste. |

When it comes to grinding and polishing, the choice of media can significantly influence the efficiency and effectiveness of the process. Zirconia ball media stands out for its exceptional durability and performance. The high density and hardness of zirconia balls ensure a faster and more uniform grinding action, resulting in a smoother finish with less material waste. This translates to reduced processing times and lower operational costs, making it an ideal choice for various applications.

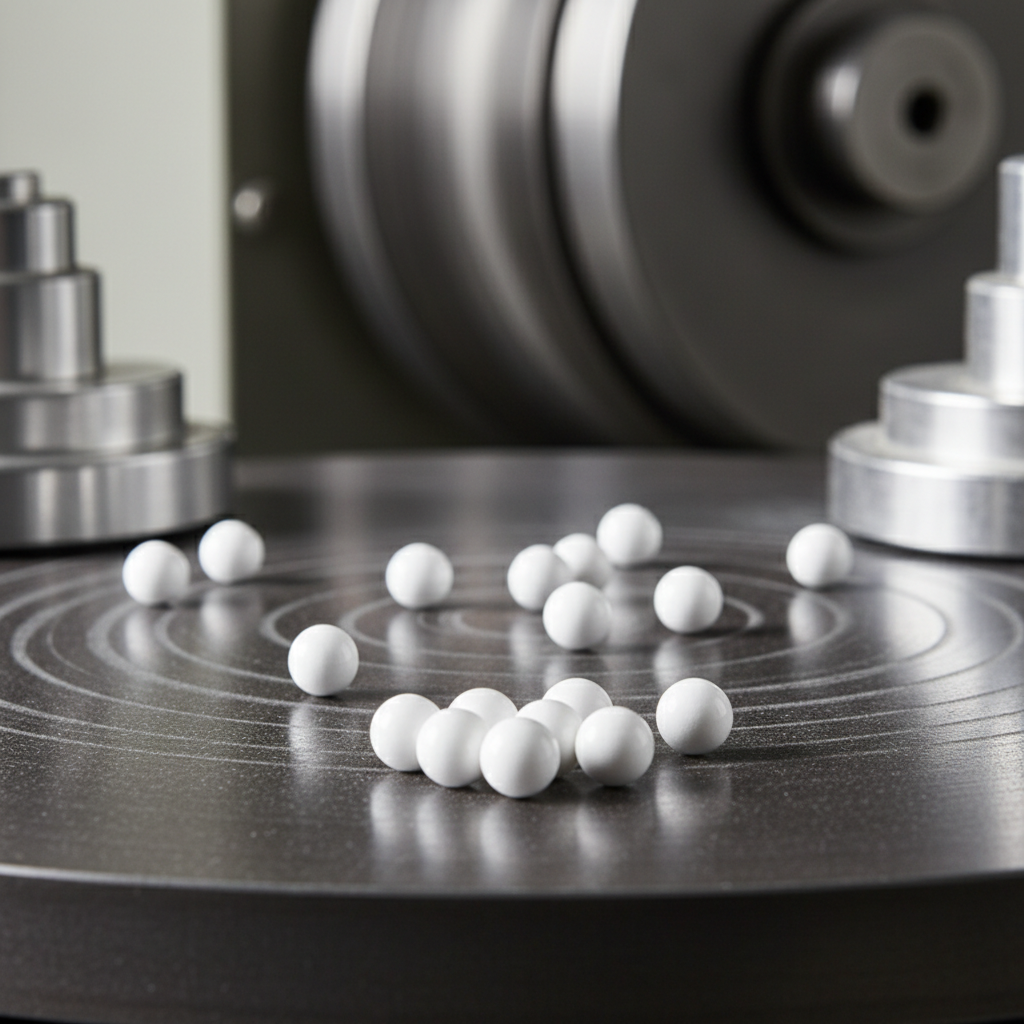

Tips: For optimal efficiency, consider using a media size that matches your specific grinding requirements. Smaller zirconia balls can provide a finer finish, while larger ones may enhance the removal rate when dealing with coarse materials. Additionally, maintaining the correct media-to-material ratio is crucial - a well-balanced mix can enhance performance and extend the lifespan of the media.

Another vital aspect to consider is the application of appropriate additives during the grinding process. These additives can improve the effectiveness of the zirconia balls, leading to an even better finish. Regular monitoring and adjustment of your grinding parameters can further refine the process, ensuring that you're maximizing the potential of zirconia ball media in your operations.

Zirconia ball media has emerged as a preferred choice for many industries due to its exceptional durability and longevity. Unlike traditional materials such as steel or glass, zirconia offers superior resistance to wear and tear, which significantly enhances its lifespan. This is particularly important in grinding and polishing applications where equipment must endure repetitive impacts and friction without degrading quickly. The robust nature of zirconia minimizes the risk of breakdown, leading to fewer replacement cycles and ultimately reducing operational costs.

Furthermore, zirconia’s high density contributes to its efficiency in both grinding and polishing processes. When used in mills or tumblers, the heavy balls provide consistent pressure, resulting in a finer finish on the materials being processed. Their ability to maintain structural integrity under high-stress conditions means that users can achieve superior results faster and with less energy expenditure. Thus, choosing zirconia ball media not only ensures longevity but also enhances productivity and quality in various applications.

Zirconia ball media has gained a reputation for its versatility across a wide range of industries, making it an excellent choice for grinding and polishing applications. Its exceptional hardness and wear resistance allow it to perform effectively in diverse environments, from the manufacturing of ceramics to the processing of metals. In the ceramics industry, zirconia media is often used to refine materials and achieve a polished finish, ensuring that products meet high aesthetic and functional standards. Its ability to withstand high temperatures and pressures further enhances its utility in demanding applications.

In the metalworking sector, zirconia balls are equally valuable. Their durability and low porosity make them ideal for achieving a smooth surface finish on various metal components. Whether used in vibratory finishing or tumbling processes, zirconia media contributes to increased efficiency and reduced processing times. Additionally, in the electronics and aerospace industries, where precision is paramount, the consistency and high performance of zirconia ball media ensure that even the most intricate parts are ground and polished to perfection, thereby meeting stringent quality requirements. The adaptability of zirconia media across these different fields underscores its essential role in modern manufacturing and finishing processes.

When it comes to grinding and polishing, zirconia ball media stands out as a cost-effective solution that balances quality and budget. These media not only provide impressive durability and performance but also offer long-term savings. By choosing zirconia balls, you can reduce the frequency of replacements compared to other materials, ensuring that your operations remain efficient without compromising on quality.

**Tips:** To maximize the cost-effectiveness of zirconia ball media, consider using the right size and type of balls for your specific application. This can enhance performance while minimizing wear and tear. Additionally, monitor the usage closely; overloading can lead to increased costs in the long run due to faster degradation and more frequent replacements.

Selecting zirconia balls also enables you to achieve superior results with less energy expenditure. Their density and hardness allow for effective material removal, ensuring that you can maintain high standards of finish and polish while keeping operational costs manageable. Regular maintenance and cleaning of the grinding equipment will further enhance the lifespan of zirconia ball media, making it a smart investment for any business.