Choosing the right Micro Zirconia Ball can significantly impact your project. These small yet powerful beads serve various applications in industries, including ceramics and dental care. Selecting the ideal Micro Zirconia Ball requires careful consideration of multiple factors.

Size and density are two key dimensions. A mismatch can lead to poor performance. Also, pay attention to the ball's finish. A rough surface may not provide the desired result. These specifics are crucial for achieving the intended outcome.

While it may seem straightforward, many overlook the details. The wrong choice could lead to frustrating setbacks. Reflect on your project's unique needs to make an informed decision. Different applications demand different characteristics in a Micro Zirconia Ball. Prioritizing these aspects will ensure you meet your specific requirements effectively.

Micro zirconia balls are small, durable spheres made from zirconium oxide. They are known for their high strength and low wear. These properties make them ideal for various applications. In industries like dental, automotive, and electronics, micro zirconia balls can be essential. Their ability to withstand extreme conditions makes them a reliable choice.

In the dental industry, these balls are used in the production of crowns and bridges. Their aesthetic quality is significant, as they can mimic natural tooth appearance. In automotive applications, they often serve in bearings and valves. However, not all micro zirconia balls perform equally. Some may degrade faster than expected, leading to potential operational issues.

Choosing the right micro zirconia ball requires careful consideration. Evaluate the specific requirements of your application. Factors like size, shape, and intended use are crucial. It may be helpful to seek advice from experts in the field. Sometimes, trial and error is necessary to find the perfect match. Reflect on your previous experiences; they can guide your future choices.

Selecting the right micro zirconia balls can be challenging. Consider a few key factors before making your choice. Size is crucial. Different applications require different diameters. For example, if you're working with fine materials, smaller balls may be more effective.

Another vital factor is density. Higher density balls offer better durability and stability. However, this can lead to higher costs. Evaluate your budget carefully. What might seem like a small difference can impact productivity. The application process also plays a significant role. Each use case may require different physical characteristics.

Finally, don’t overlook the surface finish. A smoother finish can reduce friction, but it may not be suitable for all tasks. Testing a few options could be beneficial. Sometimes, trial and error provide the best insights. Finding the right match may take time. Reflect on what worked and what didn’t in previous projects.

Choosing the right micro zirconia ball can be challenging. Various grades and quality levels exist, impacting performance. For industrial applications, the ball's hardness is crucial. Some reports indicate that higher-grade zirconia offers better resistance to wear and impact.

When comparing grades, consider the toughness and density. A typical micro zirconia ball has a density of about 6.0 g/cm³. Conversely, lower grades may have inconsistencies, affecting reliability. Such discrepancies can lead to higher failure rates in machinery. A manufacturer’s consistency also significantly influences quality.

It’s worth noting that smaller balls, often below 1mm, can be difficult to produce consistently. Even with advanced techniques, batch variations arise. These inconsistencies may hinder application performance. Thus, ensure to evaluate suppliers based on their quality control measures. Cost shouldn’t be the only factor; precision and reliability must also factor into your decision.

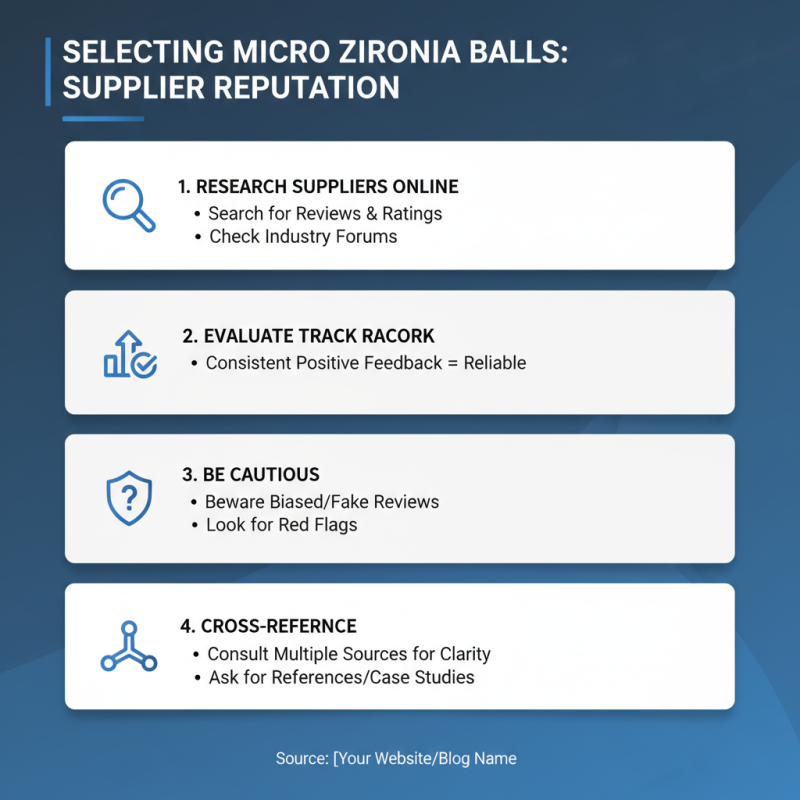

When selecting micro zirconia balls, evaluating supplier reputation is crucial. Start by researching suppliers online. Look for reviews and ratings that reflect their track record. A reliable supplier often has consistent positive feedback. However, be cautious; not every review can be trusted. Some might be biased or fake. Seeking multiple sources can help create a clearer picture.

Product reliability is equally important. High-quality micro zirconia balls should meet specific performance standards. Check for certifications or test results. Even the smallest defect can lead to significant performance issues in your application. However, not all suppliers openly share this information. If it’s not available, don't hesitate to ask for documentation. Clarity is vital in this decision-making process.

Supplier communication can also indicate reliability. A reputable supplier should respond promptly to inquiries. If they take too long, consider it a red flag. Open communication can ease doubts and build trust. Reflect on your needs and expectations. A bit of research can save you from major hassles later on.

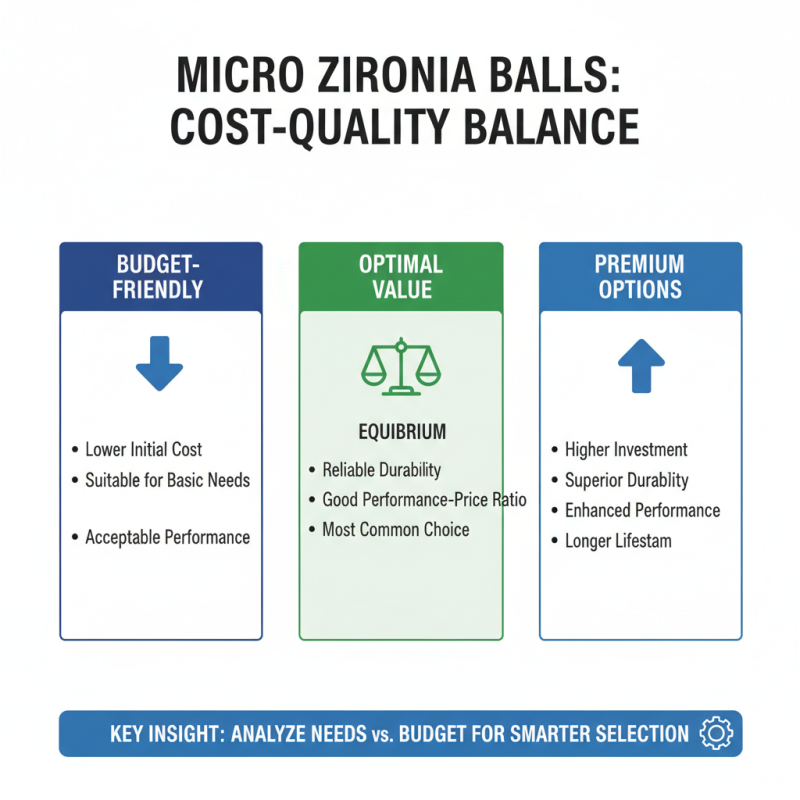

Choosing the right micro zirconia ball involves a careful cost analysis. Price variations can influence your final decision. It's essential to find the right balance between quality and budget. Higher-priced options often promise better durability and performance. However, some lower-cost variants may still meet your needs effectively.

Tips: Look for supplier reviews. Real-world feedback can guide your selection. A product with excellent recommendations might be worth the extra expense. Check for warranties or guarantees. They can provide peace of mind and reflect the manufacturer’s confidence.

It's important to analyze your specific requirements. Consider the application, environment, and performance expectations. Sometimes, opting for a mid-range option can save you money without sacrificing crucial features. Reflect on what truly matters to your project. Cutting corners can lead to frustration and extra costs in the long run. Always weigh the potential risks of a cheaper alternative.