When selecting the right 6mm Zirconia Ball, it's essential to consider various factors. Dr. Emily Chen, a materials science expert at XYZ University, notes, "Choosing the right zirconia ball can significantly impact your project’s success." Her insight serves as a guiding principle in this niche industry.

The 6mm Zirconia Ball is widely used in different applications, from precision engineering to dental practices. They offer high durability and versatility, but not all options are created equal. It’s crucial to assess the specific requirements of your project. Do you need a ball for high-speed operations? Or perhaps one that withstands immense pressure?

While exploring options, keep in mind that pricing and quality often vary. Sometimes, a cheaper choice leads to performance issues. It’s a balancing act—prioritize your needs and do thorough research. The right 6mm Zirconia Ball could make all the difference, but choosing poorly could mean wasted resources. Reflect on what truly matters for your application before making your decision.

When choosing the right 6mm zirconia ball, understanding its unique properties is crucial. These balls are known for their high strength and durability. They can withstand significant pressure and stress. This makes them ideal for various applications such as grinding and polishing. The hardness of zirconia allows it to maintain its shape, even under harsh conditions.

However, not all zirconia balls are created equal. The manufacturing process may affect their performance. Some may have slight imperfections, which can impact their efficiency. It's essential to examine factors like density and grain structure. These details can influence how well the balls perform in your specific use case.

In certain scenarios, you may find that a ball does not meet expectations. For example, it might wear down faster than anticipated. Reflecting on these outcomes helps make better choices in the future. Each application may require a different property balance, leading to unique challenges. Therefore, careful consideration of these properties will ensure you select the right zirconia ball.

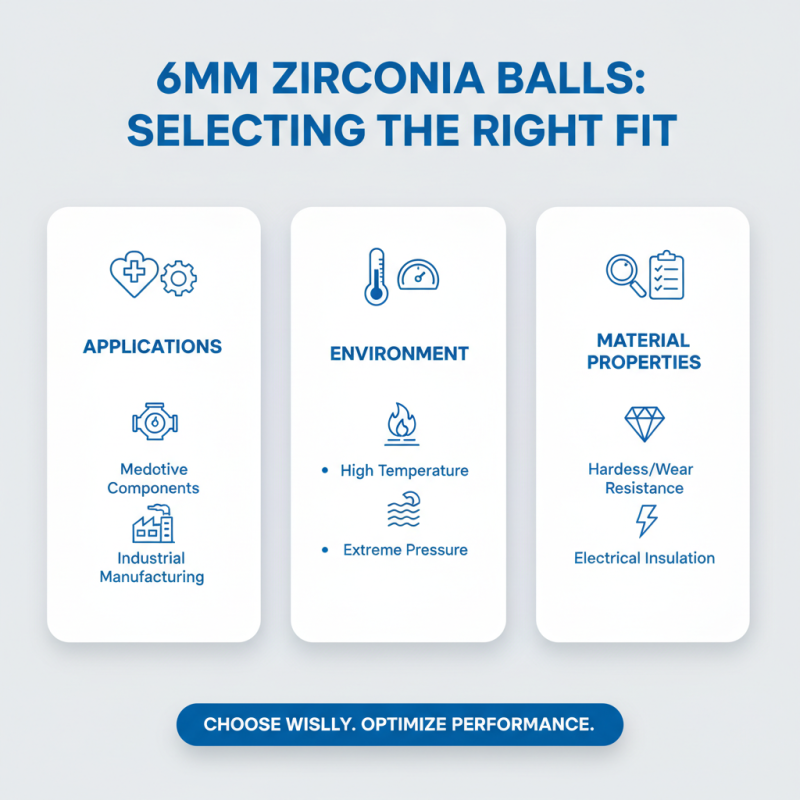

When selecting the right 6mm zirconia ball, understanding your specific application needs is crucial. These balls are versatile. They can serve in various industries, such as medical, automotive, and manufacturing. Think about where you plan to use them. Will they be exposed to high temperatures or extreme pressures? Each environment requires different properties.

Tips: Assess the environment carefully. A typical zirconia ball may not withstand all conditions. Conduct thorough research. What are the mechanical properties you require? Look into wear resistance, toughness, and corrosion resistance. These factors are significant in ensuring you select the right ball.

Consider the size and weight of your application. Is the 6mm diameter appropriate? It might seem minor, but even a slight variation can impact performance. Test samples if possible. This allows you to gauge performance under real-world conditions. Sometimes the ideal choice is not the most obvious one.

Tips: Gather feedback from peers. Their experiences can provide valuable insights. Ensure that you balance performance with cost. Not all high-performance options fit every budget. Reflect on your needs to make a well-informed choice.

When evaluating 6mm zirconia balls, quality indicators play a crucial role in selection. First, consider the composition. High-purity zirconia typically offers better durability and performance. Reports indicate that the best zirconia balls contain over 90% zirconium dioxide. This level of purity enhances mechanical stability, ensuring that these balls can withstand rigorous applications.

Another essential factor is the manufacturing process. The sintering temperature can significantly affect the strength and toughness of zirconia balls. Industry data suggest that balls sintered at temperatures exceeding 1450°C show superior hardness. However, some lower-quality options may not adhere to these temperature standards, leading to a higher likelihood of fractures. This variability can impact your project, especially under high-stress conditions.

Finally, surface finish matters greatly. A smoother surface reduces friction and wear, which is vital in applications like precision grinding. However, achieving this finish can be inconsistent. Some manufacturers focus on aesthetic appeal over functional quality. This situation can lead to unanticipated issues during usage, highlighting the importance of thorough research. Finding the right balance among these indicators ensures that your selected 6mm zirconia balls meet your specific needs effectively.

Choosing the right 6mm zirconia ball can be challenging. With many suppliers available, it’s crucial to compare their offers. Prices vary significantly, so understanding what you get for your investment is essential. Some suppliers may provide lower prices but compromise on quality. Always ask for specifications when in doubt.

Tips: Look for suppliers who offer sample balls. Testing a small quantity can help you gauge quality. Also, consider the supplier's reputation. Customer reviews can provide insights into reliability and service.

When comparing prices, consider shipping and handling costs too. Some suppliers might seem cheaper initially but charge more for delivery. This can affect your overall budget. Evaluate the complete cost before making decisions.

Tips: Don’t rush the process. Take time to research each option. Ask questions if something isn’t clear. A thorough understanding prevents mistakes later. Compare different suppliers, but remember that quality should remain your primary focus.

| Supplier | Material Quality | Price per Unit | Minimum Order Quantity | Lead Time |

|---|---|---|---|---|

| Supplier A | High | $0.50 | 100 units | 2 weeks |

| Supplier B | Medium | $0.40 | 50 units | 1 week |

| Supplier C | High | $0.55 | 200 units | 3 weeks |

| Supplier D | Low | $0.30 | 500 units | 1 month |

When considering the maintenance and longevity of 6mm zirconia balls, several factors come into play. Zirconia balls are known for their hardness and wear resistance. According to industry reports, they can last up to five times longer than traditional ceramic materials. However, their longevity greatly depends on the operating environment and care taken during use.

A common oversight is neglecting to monitor the working conditions. High temperatures and corrosive environments can drastically reduce the lifespan of zirconia balls. Regular inspections are crucial. They help identify wear or degradation early. Elevated temperatures lead to significant thermal stress.

Tips: Always inspect for signs of wear. Regular cleaning can enhance performance. Use appropriate lubricants to reduce friction and wear.

Zirconia balls are also sensitive to shock loads. Excessive force can lead to cracking. Take note of the loading conditions. Review the manufacturer's guidelines for best practices. Allocate time for maintenance routines, even if it seems unnecessary. Reflecting on these details helps prolong the life of your zirconia balls, ensuring better efficiency in your applications.

This chart illustrates the performance metrics of 6mm zirconia balls across various categories. Each metric is rated on a scale from 0 to 100, providing insights into hardness, wear resistance, corrosive resistance, temperature stability, and impact strength, crucial for selecting the appropriate zirconia ball for specific applications.