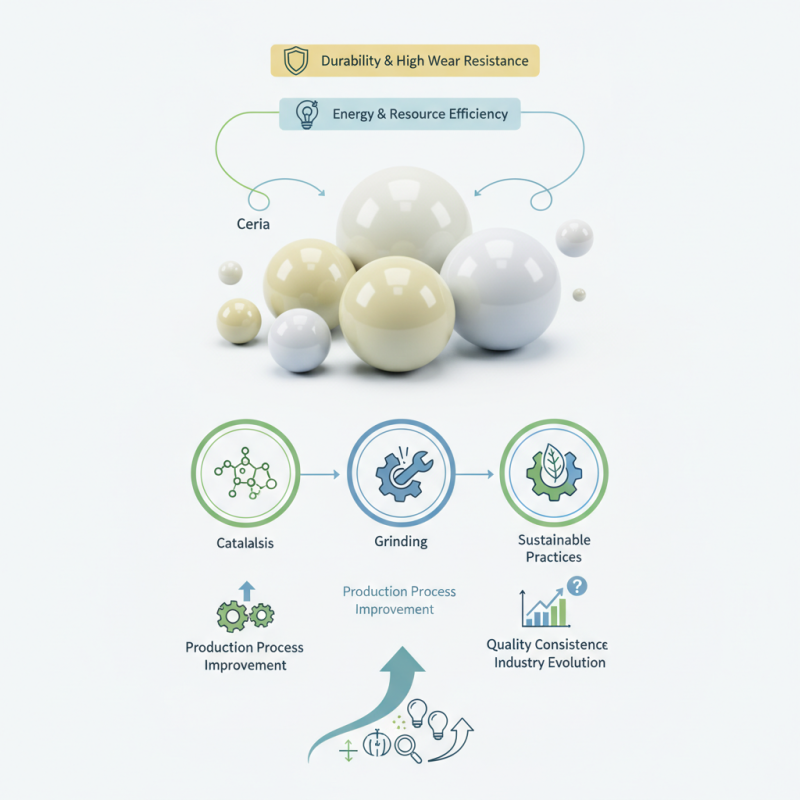

In the world of materials science, the Ceria Zirconia Ball plays a crucial role. Dr. Emily Chen, a leading expert in advanced ceramics, states, "Ceria Zirconia Balls enhance the performance of various industrial processes." This innovative product is essential for applications in catalysis and grinding.

The unique properties of Ceria Zirconia Balls make them valuable. They offer durability and high resistance to wear. These characteristics lead to efficiency in energy and resource use. However, there remains a need for continual improvement in production processes. Maintaining consistency in quality can be challenging.

Industries relying on these balls are evolving rapidly. There is potential for further innovations. As we explore the significance of Ceria Zirconia Balls, we should also reflect on the environmental impact of their production. Sustainable practices are vital for future growth in this sector.

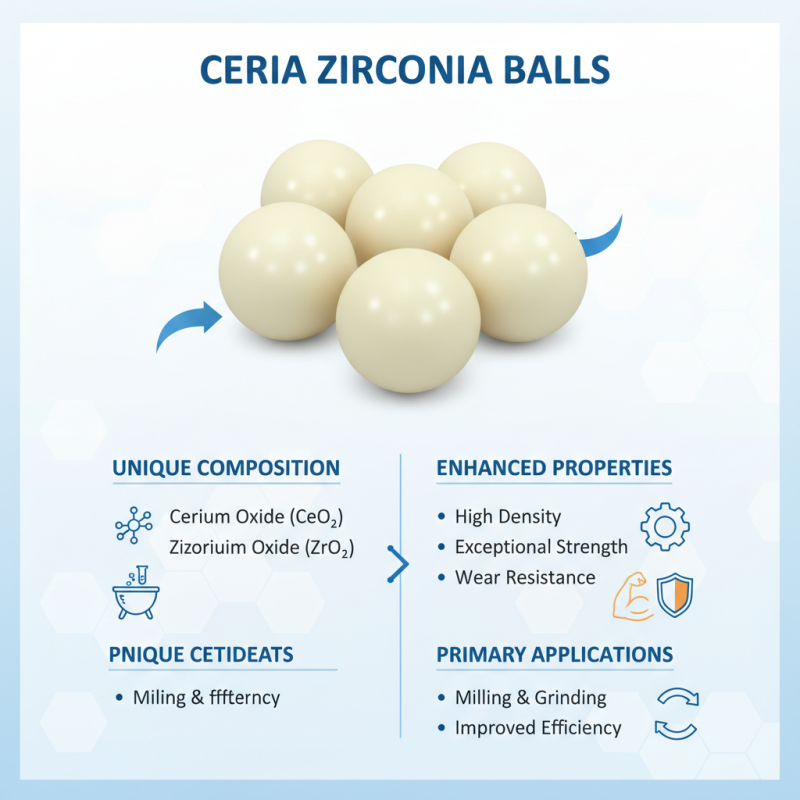

Ceria zirconia balls are innovative materials used in various industries. Composed mainly of zirconium oxide, they exhibit remarkable properties. Their distinguishing feature is the inclusion of cerium oxide, which enhances their stability and performance. This combination leads to improved resistance to wear and chemical degradation.

In manufacturing, ceria zirconia balls play a pivotal role in grinding and milling processes. They deliver consistent results, making them a preferred choice for high-precision tasks. Many industries benefit from their use, but not every application showcases their potential effectively. It’s essential to evaluate how these balls perform under different conditions.

Their spherical shape also facilitates smooth motion, reducing friction significantly. However, users sometimes overlook the appropriate conditions for optimal performance. Experimentation is key to unlocking the full advantages of ceria zirconia balls. Each application may reveal unique challenges that require thoughtful adjustments and learning from mistakes.

Ceria zirconia balls are made from a unique combination of cerium oxide and zirconium oxide. This composition offers enhanced mechanical properties. The high density and strength of these balls allow them to withstand harsh conditions. They are often used in milling and grinding processes, improving efficiency.

These balls have exceptional wear resistance. Their structure supports durability, even in high-pressure environments. However, not all applications benefit equally from ceria zirconia balls. Some may find the cost prohibitive.

Ceria zirconia balls also provide excellent thermal stability. This quality makes them suitable for high-temperature applications. On the flip side, the manufacturing process can be complex and costly. Users may need to assess whether the benefits justify the investment. The balance between performance and expense requires careful consideration.

Ceria zirconia balls are gaining traction across multiple industries. Their unique properties make them beneficial in several applications. For instance, in the ceramics industry, ceria zirconia balls serve as grinding media. This is crucial for producing fine powders essential in making ceramic products.

In the coating industry, ceria zirconia balls play a vital role in enhancing the performance of coatings. Reports indicate that their use improves the durability and wear resistance of coatings by up to 30%. This is essential for industries such as automotive and aerospace, where product longevity is key.

However, challenges remain. The manufacturing process of ceria zirconia balls can be complex and costly. Some companies struggle to maintain consistency in quality. Furthermore, environmental regulations may impact production methods. Adopting eco-friendly practices could add to operational costs. Balancing these factors is crucial for maximizing benefits while minimizing drawbacks.

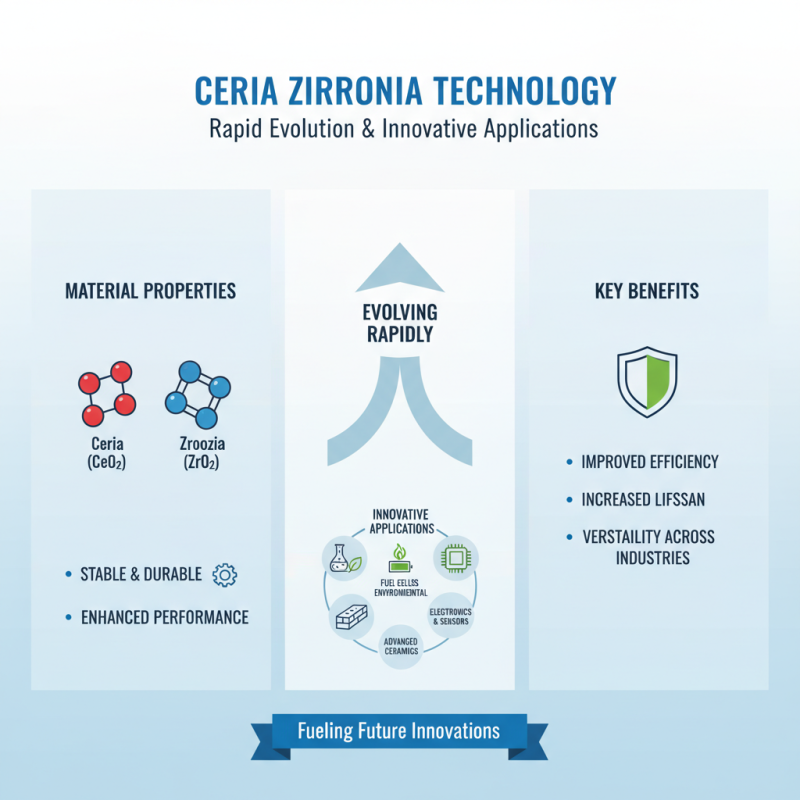

Ceria zirconia balls have gained attention in material science. Their unique properties make them useful in various applications. These include catalysis, ceramics, and grinding processes. The addition of ceria enhances the chemical stability of zirconia. This leads to improved performance in high-temperature environments.

In the realm of catalysis, ceria zirconia balls act as effective supports for catalytic reactions. They provide a large surface area, which boosts interactions. This enhances reaction efficiency and product yield. However, there can be challenges. Optimizing the ratio of ceria to zirconia requires careful experimentation. Too much ceria may negatively impact the desired properties.

Ceria zirconia balls also benefit the milling and grinding industries. Their durability and resilience reduce wear during operation. Yet, not every application sees the same advantages. The effectiveness can vary based on the materials involved. This inconsistency highlights the need for further research and reflection in specific use cases. Ultimately, understanding these nuances can lead to breakthroughs in material science.

Ceria zirconia technology is evolving rapidly. Researchers are exploring innovative applications in various industries. The blend of ceria and zirconia forms a stable, durable material. This composition enhances performance in fields like ceramics and fuel cells.

Future trends indicate a focus on enhanced energy efficiency. Manufacturers are looking to reduce production costs while improving quality. There’s potential for using ceria zirconia in advanced coatings. These coatings can withstand high temperatures and harsh conditions. New developments might also lead to better performance in catalysis.

However, challenges remain. The synthesis process can be complex and costly. Further research is necessary to address these hurdles. Understanding the interplay of materials is crucial. Innovations must also consider environmental impacts. Balancing performance with sustainability is key for future growth.