The global market for grinding media is expected to witness significant growth in the coming years, driven by the increasing demand across various industrial sectors. Among the different types of grinding media, "Zirconia Beads For Grinding Media" have emerged as a top choice due to their unique advantages, such as high density, exceptional hardness, and superior wear resistance. According to a recent report by MarketsandMarkets, the zirconia beads market is projected to reach USD 800 million by 2025, fueled by their applications in ceramics, paint, and coatings industries.

The ability of zirconia beads to provide efficient grinding and dispersion makes them superior to traditional media options. In addition, advancements in technology are leading to the development of even more effective zirconia formulations, which enhance performance while driving down operational costs. Research from various industry analysts indicates that the adoption of zirconia beads is likely to grow by over 10% annually during this period, as more manufacturers seek solutions that optimize production efficiency and reduce environmental impact.

In light of these trends, understanding the benefits of zirconia beads for grinding media becomes imperative for industry stakeholders. Their unique properties not only enhance product quality but also contribute to greater sustainability in manufacturing processes, making them a key focus for innovation in various applications. As the demand for finer and more consistent particle sizes continues to rise, zirconia beads will play a crucial role in shaping the future of grinding media technology.

Zirconia beads have emerged as a pivotal component in various industries, particularly for their applications in grinding media. In sectors like ceramics, paints, and pharmaceuticals, zirconia beads provide enhanced efficiency and lower contamination levels. According to a recent report by Market Research Future, the global market for zirconia grinding media is projected to witness a compound annual growth rate (CAGR) of 6.5% through 2025. This growth is fueled by the beads' superior mechanical strength and wear resistance, which significantly outperforms traditional materials like glass and steel.

One of the notable advantages of zirconia beads is their ability to minimize wear and tear on machinery while maximizing performance. The beads possess a high density and smooth surface finish, which allows for efficient particle size reduction and improved processing times. Furthermore, their low fracture rate ensures longevity and reduced downtime in industrial applications. A study by the International Journal of Advanced Manufacturing Technology highlighted that the use of zirconia beads can reduce product contamination levels by up to 30%, making them an ideal choice for sensitive environments such as the pharmaceutical industry.

Tips: When selecting grinding media for your application, consider not only the material's hardness but also its density, as higher density beads tend to provide superior grinding efficiency. Additionally, ensure the compatibility of the grinding media with your specific material to enhance overall performance. Regularly assess the wear rate of the beads to optimize production efficiency and maintain high-quality standards in your processes.

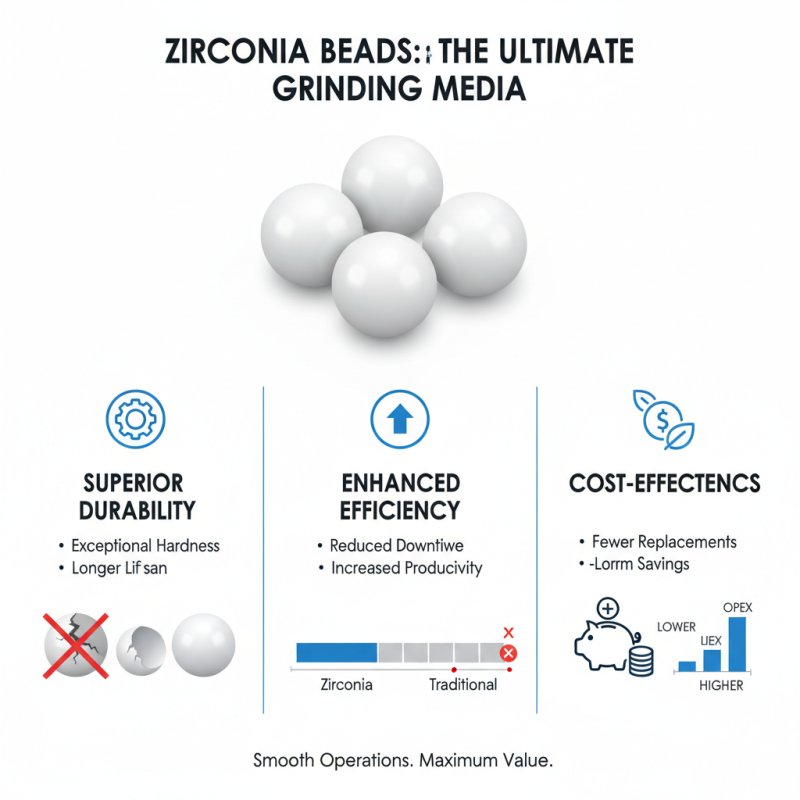

Zirconia beads have emerged as a premier choice for grinding media in various industries due to their exceptional durability and longevity. A recent report by the International Journal of Advanced Manufacturing Technology highlights that zirconia grinding media possess a hardness rating of 1200 HV, significantly higher than that of traditional materials such as glass or ceramic beads. This remarkable hardness allows zirconia beads to withstand extensive wear and tear, making them ideal for high-energy milling processes where resistance to abrasion is critical.

In addition to their hardness, zirconia beads offer an extended lifespan, which translates to lower operational costs over time. According to a study published in the Journal of Materials Science, the use of zirconia beads can lead to a reduction in media consumption by up to 30% in comparison to conventional grinding media. This reduction not only decreases material costs but also minimizes downtime associated with media replacement. Furthermore, the smooth surface of zirconia beads ensures minimal contamination of the ground products, maintaining the purity of the materials processed. As industries continue to prioritize efficiency and sustainability, the enhanced durability and longevity of zirconia grinding media position them as the optimal choice for grinding applications in 2025 and beyond.

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Durability | Zirconia beads are known for their exceptional resistance to wear and breakage, leading to prolonged life cycles. | Reduces replacement costs and downtimes, improving operational efficiency. |

| Fine Particle Size Distribution | Zirconia beads ensure a uniform and consistent particle size, enhancing grinding efficiency. | Improves product quality and reduces processing time. |

| Chemical Inertness | Zirconia exhibits low reactivity with various chemicals, preventing contamination in sensitive applications. | Ensures purity in the final product, critical for industries like pharmaceuticals and food processing. |

| High Density | The high density of zirconia aids in efficient energy transfer during the grinding process. | Enhances the speed and effectiveness of the grinding cycle. |

| Reduced Noise Levels | Zirconia beads tend to generate less noise compared to other grinding media. | Creates a quieter working environment, which can enhance worker comfort. |

Zirconia beads are rapidly gaining traction in various industries as an effective grinding media, particularly in 2025. Their unique composition offers improved efficiency in grinding processes, primarily due to their high density and durability. This allows for enhanced performance in both wet and dry grinding applications, resulting in finer particle sizes and a more uniform distribution. The exceptional wear resistance of zirconia beads minimizes the need for frequent media replacement, thus reducing downtime and operational costs.

For those considering the switch to zirconia beads, here are a couple of tips: first, ensure that you select the right size and density of beads for your specific grinding application. Matching these parameters to your equipment will optimize performance and efficiency. Secondly, monitor the bead-to-particle ratio during the grinding process to maintain an effective balance that maximizes grinding efficiency while minimizing wear and tear on both the media and the machinery.

Implementing zirconia beads can significantly boost productivity, making them a vital component for industries focused on precision and quality in their grinding processes. As 2025 approaches, transitioning to this advanced media could set businesses apart in competitive markets.

This chart illustrates the anticipated improvements in grinding efficiency when using zirconia beads as grinding media in 2025. As shown, the benefits include enhanced wear resistance, reduced contamination levels, and increased throughput rates compared to traditional grinding media.

Zirconia beads have emerged as a leading choice for grinding media due to their exceptional durability and efficiency. When considering long-term applications, the cost-effectiveness of using zirconia beads becomes particularly significant. Unlike traditional grinding media, zirconia beads offer a longer lifespan, reducing the need for frequent replacements. This longevity not only translates into savings on purchase costs but also minimizes downtime in production processes, allowing for smoother operations and increased productivity.

Tips: When selecting zirconia beads, it’s essential to evaluate factors such as the specific grinding application and operating conditions to ensure optimal performance. Additionally, monitoring the wear rate can help in preemptively managing replacements, keeping operational costs low.

Moreover, the overall energy efficiency of zirconia beads plays a crucial role in reducing long-term expenses. Their higher density and smooth surface enhance grinding efficiency, leading to faster processing times while consuming less energy. This combination of performance and cost savings underscores the advantage of using zirconia beads in various industries, making them a smart investment for businesses looking to optimize their manufacturing processes.

Zirconia beads have gained prominence as a preferred grinding media due to their superior performance and minimal environmental impact. As industries increasingly adopt sustainable practices, the use of zirconia beads offers several eco-friendly benefits. Unlike traditional grinding materials, zirconia beads are non-toxic and inert, leading to reduced hazardous waste. According to a recent report by the International Journal of Environmental Research, replacing conventional grinding media with zirconia can lower harmful emissions by up to 30%, making the manufacturing process substantially greener.

The durability of zirconia beads also enhances sustainability in manufacturing operations. Their high resistance to wear and tear means they have a longer lifespan compared to other materials, resulting in lower replacement frequency and less material waste. Studies show that switching to zirconia can decrease overall operational costs by approximately 20%, as well as substantially reducing the energy consumption associated with the grinding process. This combination of longevity and efficiency emphasizes the need for industries to consider zirconia as a viable option for sustainable manufacturing.

Tips: When looking to implement zirconia beads in your operations, consider conducting a lifecycle analysis to quantify both environmental impact and cost savings. Additionally, engage with suppliers who emphasize responsible sourcing and production methods to further enhance your sustainability goals. Making informed choices can significantly align your manufacturing practices with ecological preservation while maintaining high performance standards.