In the realm of industrial applications, Yttria Zirconia Beads have emerged as a cornerstone material, renowned for their superior performance and versatility. Experts in the field, such as Dr. Emily Harrison, a leading materials scientist, have emphasized the transformative impact of these beads, stating, "Yttria Zirconia Beads represent a breakthrough in precision grinding and dispersion technology, offering unmatched durability and efficiency." This powerful endorsement highlights the significance of incorporating Yttria Zirconia Beads into various industrial processes.

The unique properties of Yttria Zirconia Beads, including their hardness, wear resistance, and thermal stability, make them ideal for applications ranging from ceramics to energy production. As industries strive for enhanced productivity and quality, these beads not only facilitate exceptional grinding results but also contribute to cost-effectiveness and longer equipment life. By exploring the top ten benefits of Yttria Zirconia Beads, we can gain valuable insights into how they are reshaping industrial standards and driving innovation across multiple sectors.

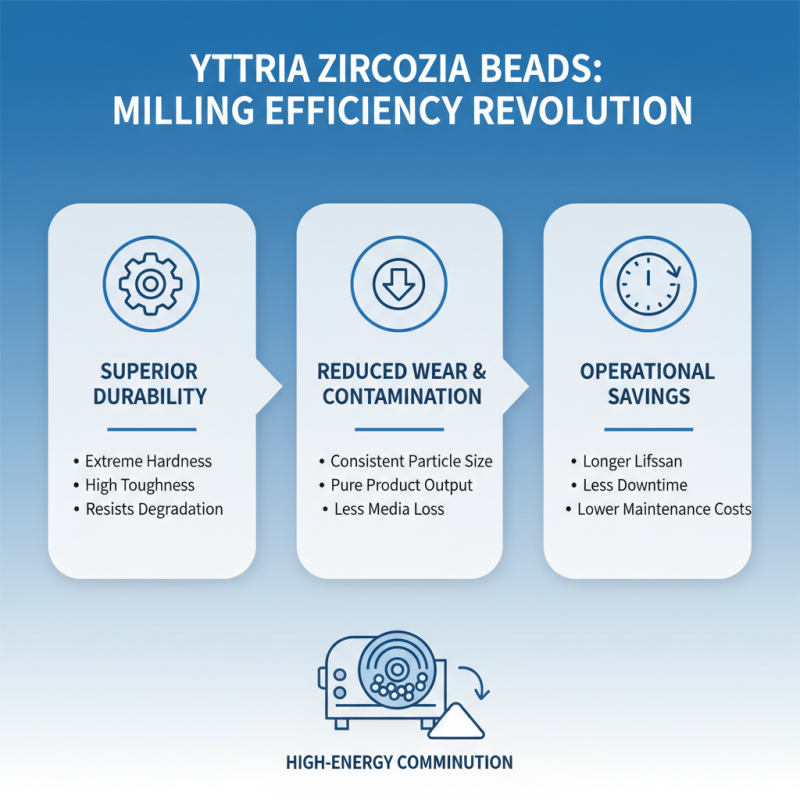

Yttria zirconia beads are increasingly recognized for their effectiveness in reducing wear during milling processes. Their superior hardness and toughness make them ideal for high-energy comminution applications, allowing for consistent particle reduction without significant degradation of the beads themselves. This leads to longer operational lifespans and a more efficient milling process, ultimately reducing downtime and maintenance costs for industries relying on these materials.

Tips for selecting yttria zirconia beads include considering the specific milling application and the type of materials being processed. Larger beads may be more effective for breaking down hard raw materials, while smaller beads can be used for finer milling of softer substances. Additionally, evaluating the density and roundness of the beads can significantly impact the milling efficiency and the final product's quality.

Another advantage of using yttria zirconia beads is their chemical stability, which means they do not react with the materials being milled. This is particularly beneficial in industries where contamination is a concern, as it ensures purity in the final products. By carefully selecting the right yttria zirconia beads based on your specific needs, you can optimize the milling process while minimizing wear and maintenance issues.

Yttria zirconia beads are gaining recognition in industrial applications due to their exceptional ability to enhance uniformity in particle size distribution. This attribute is crucial for industries that require precise formulations, such as pharmaceuticals, cosmetics, and advanced materials. The uniform particle size not only ensures consistent performance in processes such as milling and dispersion but also contributes to improved product quality and reliability. With these beads, manufacturers can achieve tighter tolerances and optimize their production processes, resulting in less waste and increased efficiency.

Tips for Achieving Uniformity: When utilizing yttria zirconia beads, it's essential to monitor the bead size and distribution closely. Regularly calibrating your equipment and conducting particle size analysis can help maintain the desired uniformity. Additionally, ensuring that the beads are used at the right concentrations within your mixtures can significantly impact the efficiency of dispersion and milling processes.

Another benefit of yttria zirconia beads is their durability, which allows them to maintain their size and shape during prolonged use. This resilience minimizes the risk of contamination and ensures that your particle size distribution remains consistent over time. To maximize this advantage, consider implementing regular maintenance routines for your equipment and selecting optimal milling parameters tailored to the properties of yttria zirconia beads.

Yttria-stabilized zirconia beads have gained significant attention in various industrial applications due to their exceptional toughness and durability. These beads exhibit a high fracture toughness, reported to be around 10 MPa·m0.5, making them ideal for demanding environments such as grinding and milling processes. According to a study published by the Ceramic Industry Journal, the incorporation of yttria into zirconia stabilizes its cubic crystalline structure, enhancing its resistance to wear and thermal shock. This results in longer service life and reduced operational costs, making yttria zirconia beads a cost-effective solution for industries ranging from ceramics to aerospace.

To maximize the benefits of yttria zirconia beads, it's essential to choose the right size and distribution for your specific application. A finer bead size can improve dispersion and product finish, while larger beads are more effective in breaking down hard materials. Industry experts recommend conducting trials to determine the optimal bead size for your processes.

Another crucial tip is to maintain proper equipment settings to optimize the performance of these beads. Adjusting parameters like milling speed and time can significantly influence the efficiency of the grinding process. Utilizing yttria zirconia beads not only enhances the durability of your products but also increases the overall productivity of your operations.

Yttria zirconia beads have emerged as a cost-effective solution for various industrial applications, particularly in the realm of long-term manufacturing efforts. Unlike traditional grinding media, yttria zirconia beads offer superior durability and resistance to wear, which significantly reduces the frequency of replacements. This durability translates to lower operational costs over time, making them an attractive option for manufacturers looking to streamline their budgets while maintaining product quality.

Moreover, the enhanced performance of yttria zirconia beads contributes to improved processing efficiency. The beads' high density and exceptional toughness allow for better energy transfer during grinding and milling processes. As a result, manufacturers can achieve finer particle sizes more quickly, enhancing the overall productivity of their operations. This combination of durability, efficiency, and reduced replacement frequency positions yttria zirconia beads as a smart investment for companies aiming to optimize their manufacturing processes without compromising on quality or performance.

Yttria zirconia beads have emerged as a critical material in various industrial applications, not only for their superior performance but also for their environmental and sustainability benefits. The use of yttria-stabilized zirconia has shown to reduce waste significantly in manufacturing processes. According to a recent study by the International Journal of Advanced Manufacturing Technology, companies utilizing yttria zirconia beads reported a 30% reduction in waste materials compared to traditional media. This is crucial as industries face increasing pressure to find sustainable alternatives amid growing environmental concerns.

Moreover, yttria zirconia beads are recyclable, which further enhances their sustainable profile. A report from the Sustainable Materials Coalition states that the life cycle of these beads allows for reprocessing and repurposing, minimizing the overall carbon footprint associated with their production and disposal. By opting for these beads, companies not only comply with stringent environmental regulations but also contribute positively to their corporate social responsibility initiatives.

Tips: To maximize the sustainability benefits of yttria zirconia beads, ensure that your supplier participates in a closed-loop recycling program. Additionally, periodic audits of your material usage can help identify areas for further waste reduction. Always strive for continuous improvement in your industrial processes to maintain eco-friendly operations.