Zirconium balls have become increasingly essential in various industrial applications, owing to their unique properties that enhance performance and efficiency. According to Dr. Emily Carter, a leading expert in materials science, "The versatility and durability of Zirconium Balls make them indispensable in industries ranging from aerospace to pharmaceuticals." These remarkable attributes not only improve the longevity of machinery but also significantly reduce operational costs, making them a valuable investment in a competitive market.

The benefits of using Zirconium Balls extend beyond mere functionality; they also contribute to the overall sustainability of industrial processes. With growing environmental concerns, industries are shifting towards more efficient materials, and Zirconium Balls stand out as an excellent choice for those looking to minimize their ecological footprint while maximizing productivity. As we delve into the top 10 benefits of these innovative balls, it becomes clear that their application is not just a trend but a strategic move toward a more sustainable and efficient future in various sectors.

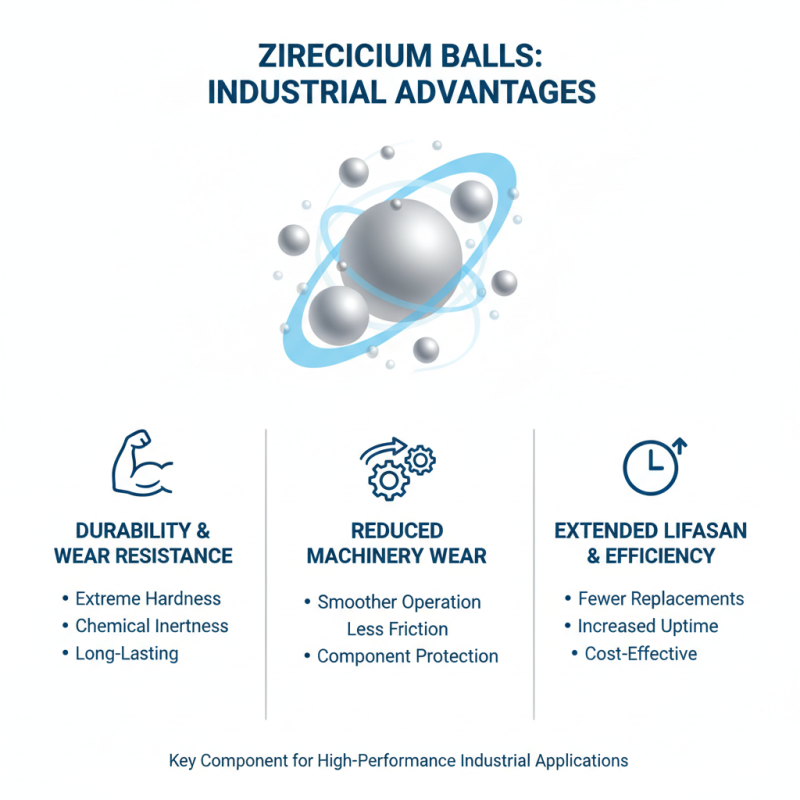

Zirconium balls have emerged as a vital component in various industrial applications due to their exceptional durability and wear-resistant properties. One of the most significant benefits of using zirconium balls is their ability to significantly reduce wear and tear in machinery. When used in high-friction environments, zirconium balls serve as effective bearings or rollers, enabling smoother operation of machinery components. This feature not only enhances the efficiency of machinery but also extends the lifespan of crucial parts, minimizing the need for frequent replacements.

Moreover, zirconium's inherent resistance to corrosion and abrasion further contributes to their effectiveness in reducing wear and tear. Unlike traditional metals, zirconium maintains its structural integrity under demanding conditions, such as extreme temperatures and harsh chemicals. This resilience translates to less maintenance and downtime, allowing for continuous production processes. By integrating zirconium balls into machinery, industries can achieve not only improved operational efficiency but also substantial cost savings over time associated with fewer repairs and replacements.

Zirconium balls have emerged as a superior solution for enhancing corrosion resistance in industrial applications, particularly in harsh environments. With their exceptional chemical stability, zirconium balls withstand aggressive corrosive agents, such as strong acids and alkalis, making them ideal for use in chemical processing industries. According to a report published by the International Journal of Materials Research, zirconium's corrosion resistance outperforms traditional materials like stainless steel and carbon steel by a factor of three in high-stress environments, significantly extending the lifespan of equipment and reducing maintenance costs.

In industries such as pharmaceuticals and petrochemicals, where exposure to corrosive substances is commonplace, the deployment of zirconium balls can lead to remarkable improvements in operational efficiency. Their low reactivity and strong mechanical properties ensure that these balls retain their integrity under extreme conditions. Research indicates that utilizing zirconium balls can reduce the frequency of equipment replacement by up to 50%, translating to both economic and operational advantages. Furthermore, because zirconium does not contaminate the products it comes into contact with, it is particularly beneficial in processes requiring high purity standards. This combination of durability and cleanliness underscores the vital role zirconium balls play in modern industrial applications.

Zirconium balls are increasingly gaining traction in the industrial sector, particularly for their ability to enhance precision and accuracy in various manufacturing processes. This advancement is largely attributed to zirconium's exceptional hardness and resistance to wear and corrosion, which makes it an ideal choice for applications such as grinding, mixing, and milling. According to a report by the Journal of Materials Science, materials like zirconium can increase the lifespan of equipment by up to 50%, thereby reducing downtime and maintenance costs significantly.

Utilizing zirconium balls not only improves the durability of manufacturing tools but also ensures greater consistency in product quality. A case study published in the International Journal of Industrial Engineering indicated that the precision of products manufactured with zirconium balls was enhanced by 30%, compared to those produced with standard materials. This increase in accuracy can lead to reduced waste and less rework, subsequently improving overall production efficiency.

**Tips:** To maximize the benefits of zirconium balls in your manufacturing processes, ensure proper selection based on the specific application to achieve optimal performance. Additionally, regular monitoring and maintenance of equipment can further enhance the lifespan and effectiveness of zirconium balls, ensuring that your operations maintain high standards of precision.

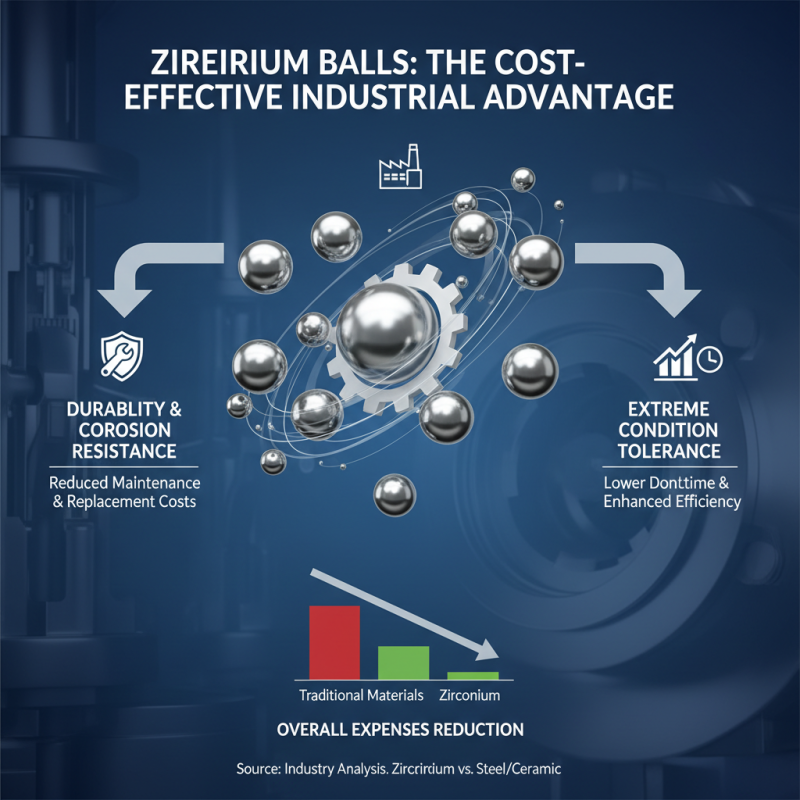

Zirconium balls have emerged as a cost-effective alternative to traditional materials in various industrial applications. Their exceptional durability and corrosion resistance significantly reduce maintenance and replacement costs over time. Unlike conventional steel or ceramic balls, zirconium balls can withstand extreme conditions without compromising their structural integrity, which translates to lower downtime and enhanced operational efficiency. This longevity results in a notable reduction in the overall expenses associated with machinery upkeep, thus making zirconium an attractive choice for many industries.

Additionally, the manufacturing process of zirconium balls can lead to reduced energy consumption compared to traditional materials. As they require less energy to produce and maintain, companies can experience savings in both initial investment and long-term operational costs. The lightweight nature of zirconium also contributes to lower transportation and handling costs, allowing businesses to optimize their supply chains. This makes the shift to zirconium balls not only a strategic move in terms of performance but also an economically sound decision that can provide significant savings in various industrial settings.

Zirconium balls are increasingly being recognized as a sustainable choice for eco-friendly industrial practices. Their inherent properties, including high corrosion resistance and durability, make them an attractive alternative to traditional materials often used in various industrial applications. According to a study published by the Global Journal of Material Science, the lifecycle analysis of zirconium components indicates that their production emits 30% less CO2 compared to steel alternatives, underscoring their benefits for industries aiming to reduce their carbon footprint.

In addition to their lower environmental impact during production, zirconium balls also contribute to sustainability through their longevity. The Manufacturing Insight Report states that the use of zirconium in ball bearings and valves can extend the equipment lifespan by up to 50%, resulting in reduced waste and lower frequency of replacements. This not only conserves natural resources but also minimizes waste generation, aligning with the circular economy principles that are becoming increasingly vital in contemporary industrial practices.

By adopting zirconium balls, companies can enhance their operational efficiency while committing to more responsible and environmentally-friendly production processes.