The 6mm Zirconia Ball has emerged as a pivotal component across various industries due to its exceptional properties, including high strength, wear resistance, and chemical inertness. According to a market report by Markets and Markets, the global ceramic balls market is anticipated to grow significantly, with the increasing demand for advanced materials in sectors such as biomedical, automotive, and aerospace. This strong growth trajectory highlights the necessity for durable and reliable components, where zirconia balls, particularly those measuring 6mm, play an integral role.

In the realm of manufacturing, the benefits of utilizing 6mm Zirconia Balls are manifold. Their ability to withstand abrasive conditions and reduce friction makes them ideal for applications in ball mills, vibratory finishing, and grinding processes. Furthermore, the advanced properties of these ceramic balls lend themselves to various high-performance applications in the pharmaceutical industry, where contamination avoidance is crucial. Industry statistics reveal that the global pharmaceutical manufacturing market is projected to reach $1.5 trillion by 2023, amplifying the need for reliable, high-quality materials.

With the ongoing innovation and research into new applications, the significance of 6mm Zirconia Balls in enhancing efficiency and product quality will likely become even more pronounced. As industries continue to embrace these high-performance components, understanding their benefits and uses will be essential for engineers and decision-makers alike.

The use of 6mm zirconia balls in the medical equipment sector has gained significant traction due to their remarkable properties, such as high strength, biocompatibility, and resistance to wear and corrosion. According to a recent industry report by Grand View Research, the global zirconia market in medical applications is expected to grow substantially, with an anticipated CAGR of 8.8% from 2021 to 2028. This growth is driven by the increasing demand for durable and reliable materials in surgical instruments, dental implants, and other medical devices.

One of the standout benefits of using zirconia balls is their ability to enhance the longevity and performance of medical equipment. Their exceptional hardness, rated at 1200 HV, makes them an ideal choice for bearings and components in various medical devices. Moreover, zirconia's inert nature ensures that it does not react adversely with biological tissues, making it an excellent material for applications that require high levels of sterility and safety.

Tips: When considering the incorporation of 6mm zirconia balls in medical applications, it's crucial to evaluate their specific compatibility with the device materials and the intended use case. It’s advisable to consult with material scientists or biomedical engineers during the design phase to ensure optimal performance. Additionally, regular maintenance check-ups are essential to leverage the full potential of zirconia balls and uphold the safety standards required in the medical field.

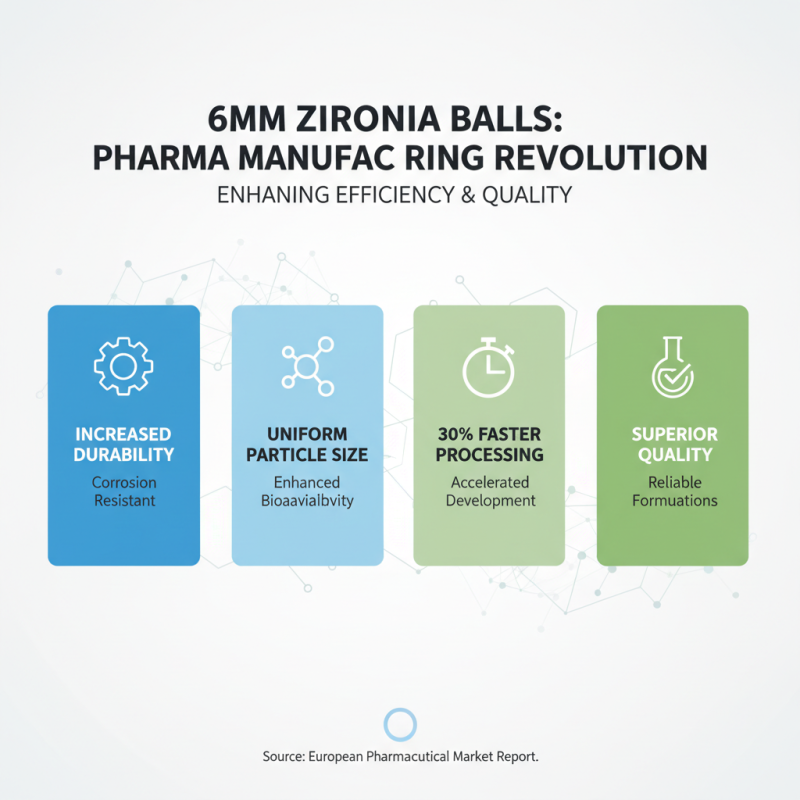

The use of 6mm zirconia balls in pharmaceutical manufacturing processes has gained traction due to their exceptional properties, which enhance efficiency and quality. Zirconia, known for its high durability and corrosion resistance, is ideal for grinding and milling applications, pivotal in the production of fine powders and suspensions. Industry studies indicate that the incorporation of zirconia balls improves the uniformity of particle size in formulations, leading to enhanced bioavailability of active pharmaceutical ingredients (APIs). According to a recent report by the European Pharmaceutical Market, utilizing zirconia milling media can reduce processing time by up to 30%, ultimately accelerating product development cycles.

Additionally, the impact of 6mm zirconia balls extends to improving cleanliness and minimizing contamination risks in pharmaceutical environments. With their non-porous surface, zirconia balls resist chemical reactions and do not leach harmful substances, thus ensuring the integrity of sensitive compounds. A survey by the Pharmaceutical Technology Journal highlighted that manufacturers report a 25% decrease in contamination incidents when switching to zirconia milling media. This advancement not only promotes compliance with stringent regulatory standards but also enhances product reliability in an industry where quality is non-negotiable.

In the aerospace and automotive industries, the use of 6mm zirconia balls has become increasingly vital due to their unique properties. Zirconia, being a highly durable ceramic material, offers exceptional wear resistance, high hardness, and the ability to withstand extreme temperatures and pressures. These characteristics make 6mm zirconia balls an excellent choice for applications such as bearings, valves, and seals. Their longevity reduces the need for frequent replacements, thereby enhancing operational efficiency and reducing maintenance costs.

Moreover, the lightweight nature of 6mm zirconia balls contributes to weight reduction in both aerospace and automotive applications. In aerospace, reducing weight is a critical factor in improving fuel efficiency and performance. In automotive applications, lighter components can lead to better fuel economy and lower emissions. Zirconia balls also exhibit excellent chemical resistance, making them suitable for use in environments where exposure to corrosive substances is inevitable.

As industries continue to innovate and push the boundaries of performance, 6mm zirconia balls are positioning themselves as essential components in the next generation of aerospace and automotive technologies.

The utilization of 6mm zirconia balls in industrial applications offers significant cost-effectiveness, making them an attractive option for various sectors. These balls, known for their durability and resistance to wear and corrosion, reduce the need for frequent replacements, ultimately lowering maintenance costs over time. Industries such as manufacturing, pharmaceuticals, and food processing benefit from this longevity, allowing companies to allocate resources more efficiently and improve their bottom line.

Additionally, the lightweight nature of zirconia balls enhances their efficiency in functions such as grinding and milling. Lower energy consumption during operations leads to reduced operational costs, promoting a more sustainable approach to manufacturing processes. Moreover, the high-performance characteristics of these zirconia balls contribute to improved product quality and consistency, which can be pivotal in competitive markets. By integrating 6mm zirconia balls, businesses not only optimize their manufacturing efficiency but also achieve significant savings, reinforcing their overall economic viability amidst fluctuating market conditions.

Recent advancements in the production and application of 6mm zirconia balls have significantly impacted precision engineering across various industries. One of the most notable technological innovations is the enhancement of the sintering process, which improves the durability and precision of these ceramic balls. Research indicates that the latest manufacturing techniques have reduced the pore size in zirconia balls, resulting in increased density and strength. According to a report by the International Journal of Advanced Manufacturing Technology, the mechanical properties of zirconia products can be enhanced by up to 30% through optimized sintering conditions, making them ideal for high-stress applications.

Furthermore, the versatility of 6mm zirconia balls extends to multiple sectors, including aerospace, automotive, and healthcare. With their low friction coefficients and excellent wear resistance, these ceramics are increasingly being utilized in precision bearing systems and components within high-performance machinery. A study published in the Journal of Materials Science highlighted that using zirconia balls in ball bearings can lead to a reduction in friction by approximately 15-20%, subsequently improving energy efficiency and longevity of the equipment. As industries continue to prioritize sustainability and operational efficiency, the role of advanced materials like 6mm zirconia balls will only grow, driving further innovations in precision engineering.

| Industry | Benefits | Common Applications | Technological Advances |

|---|---|---|---|

| Medical Devices | High wear resistance, biocompatibility | Dental implants, surgical tools | 3D printing technology for customized solutions |

| Aerospace | Lightweight, high strength | Gas turbine components, bearings | Advanced ceramic processing methods |

| Automotive | Reduced friction, improved efficiency | Engine components, valves | Nano-coating technologies |

| Electronics | High thermal conductivity, electrical insulator | Sensors, capacitors | Integration with flexible electronics |

| Manufacturing | Durability, low maintenance | Ball mills, grinding media | Improved milling processes with precision control |