The performance of ZrO2 grinding balls is crucial in various industrial applications. These ceramic balls have been recognized for their superior strength and hardness. According to a recent market report, the demand for high-quality grinding media exceeds 1 million tons annually. This rising need highlights the importance of selecting the right ZrO2 grinding ball.

Many manufacturers have focused on enhancing the properties of these grinding balls. The optimal composition of zirconia contributes to greater efficiency and longer wear life. However, inconsistencies in production methods can lead to varying performance outcomes. Some users have reported performance issues, pointing towards a need for more stringent quality control in producing ZrO2 grinding balls.

Choosing the best ZrO2 grinding ball requires understanding specific application needs. Different compositions and sizes yield different results. Despite the widespread use, many still struggle to find the perfect match for their processes. Performance can fluctuate, prompting buyers to evaluate their choices carefully. Awareness of these factors is essential for making informed purchasing decisions in the evolving market.

Zirconium dioxide (ZrO2) grinding balls come in various types, each offering unique benefits. The primary types include partially stabilized, fully stabilized, and blended zirconia balls. Each type serves different applications in industries such as ceramics, pharmaceuticals, and electronics.

Partially stabilized ZrO2 grinding balls are popular for their durability. They can withstand high temperatures and heavy workloads. These balls are often used in the production of ceramic materials. However, they may not excel in all conditions.

Fully stabilized ZrO2 balls, on the other hand, provide better performance in extreme environments. They are more resistant to wear and tear but can be more expensive.

Blended zirconia balls combine different materials to enhance properties. They can be tailored for specific applications. The choice of grinding ball significantly affects processing efficiency. Selecting the wrong type may lead to suboptimal results. Industry professionals must carefully evaluate their needs. Understanding the properties and applications of each type is crucial for enhanced performance.

ZrO2 grinding balls are gaining attention for their impressive performance characteristics. Their key properties include high strength, exceptional durability, and remarkable density. These features contribute to better grinding efficiency and longer life in various applications.

Strength is a critical attribute of ZrO2 grinding balls. They can withstand significant impacts without cracking. This makes them ideal for rigorous grinding processes. However, it's essential to ensure that they are used within their designed parameters to avoid potential failures.

Durability is another vital factor. ZrO2 balls tend to last longer than their counterparts, reducing the need for frequent replacements. This leads to lower overall costs. Yet, improperly managed wear can lead to uneven surfaces, which can affect grinding outcomes negatively.

Density plays a crucial role in performance. Higher density means better energy transfer during grinding. However, it’s crucial to balance density with other properties for optimal results.

Tip: Always monitor the condition of your grinding media. Regular checks can help identify wear patterns early. This proactive approach can save time and resources.

Tip: Choose the right size for your application. Smaller balls are better for fine grinding, while larger ones work well in coarser applications. Make decisions based on specific requirements.

| Property | Description | Value |

|---|---|---|

| Strength | Compressive strength under load | > 1000 MPa |

| Durability | Resistance to wear and tear | High resistance |

| Density | Mass per unit volume | 6.0 g/cm³ |

| Hardness | Resistance to indentation | 1200 HV |

| Thermal Stability | Performance under heat | Up to 1200 °C |

| Impact Resistance | Ability to withstand impacts | Excellent |

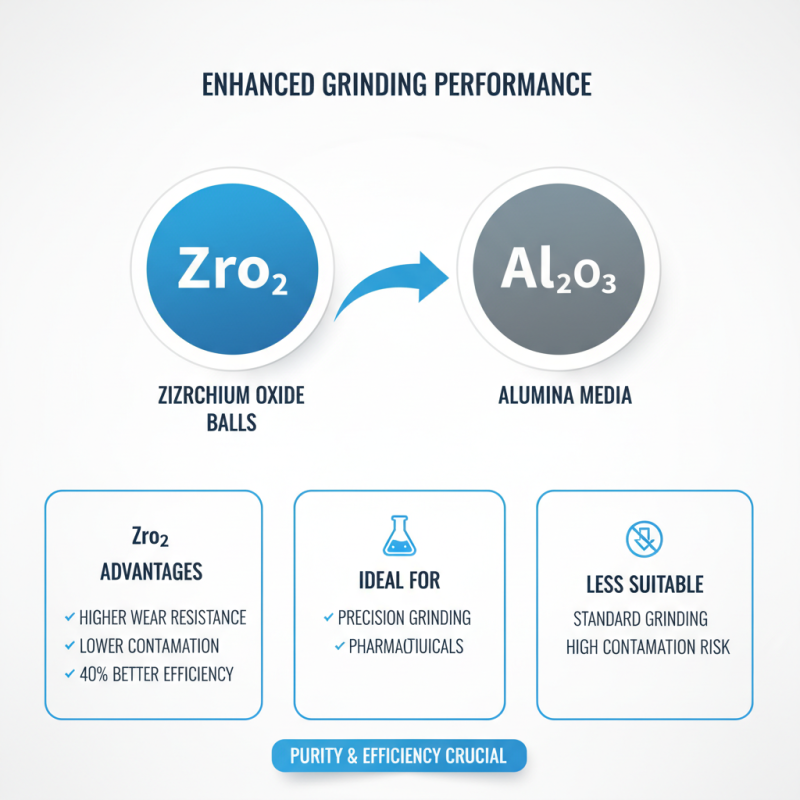

When considering grinding media for enhanced performance, ZrO2 (zirconium oxide) balls stand out against other ceramics. Research shows that ZrO2 offers higher wear resistance and lower contamination rates, making it ideal for precision grinding. In some studies, ZrO2 media demonstrated up to 40% better efficiency compared to alumina-based media. This is crucial for industries where purity is paramount, such as pharmaceuticals.

However, ZrO2 does come with higher costs. While the efficiency gains can justify the investment, it’s essential to assess your specific applications. Factors like material characteristics, desired particle size, and production volume should guide your choices. For example, if cost reduction is the priority, alternate ceramic media might suffice.

Tips: Always conduct small-scale tests before large-scale usage. Analyze the impact of different media on your grinding results. Adjust the parameters to find your optimal setup. Remember, balancing performance and cost is key for sustainable operations.

When considering ZrO2 grinding balls, industry standards play a crucial role in performance. The specifications for these materials focus on density, hardness, and wear resistance. Higher density typically leads to better impact resistance. However, not all grinding balls meet the same criteria. Some might excel in one area but fall short in another.

Parameters such as size and shape also matter. Rounder balls may offer uniformity in grinding, while irregular shapes can cause inconsistencies. Testing for these standards is essential, yet many manufacturers overlook this stage. Without rigorous testing, achieving optimal performance becomes a gamble.

The materials used in these balls can influence their performance. Purity levels in zirconia can affect durability and efficiency. Flaws or impurities can lead to premature wear or failure during operation. Thus, detailed inspections for these imperfections are necessary. Industry standards should evolve to address these gaps to better serve users. This reflects the ongoing challenge of balancing cost and quality in the grinding industry.

This chart displays the performance characteristics of ZrO2 grinding balls as of 2026. Key factors such as ball size, density, hardness, fracture toughness, and cost are crucial for optimizing grinding efficiency and selecting the best options for various industrial applications.

In the world of grinding technology, zirconia (ZrO2) grinding balls are gaining traction. Their durability and efficiency make them vital for various applications. Future trends indicate a strong focus on performance optimization. This includes refining the microstructure of ZrO2. Improved properties can lead to higher resistance and longer life span.

Tips: Always check the material composition. A small variation may lead to significant performance changes.

Another focus area is surface treatment. Enhanced surface smoothness can reduce wear and improve grinding efficiency. Manufacturers are experimenting with different treatments to achieve the optimal effect. Enhanced properties can lead to better material removal rates.

Tips: Monitor the grinding conditions. Even slight changes in parameters can impact effectiveness.

The integration of smart technology is also on the rise. Sensors can monitor the performance of grinding balls in real-time. This data can help in making informed decisions. However, relying too heavily on technology might overlook simple, practical solutions. Always reflect on traditional methods before fully committing to new tech advancements.