01

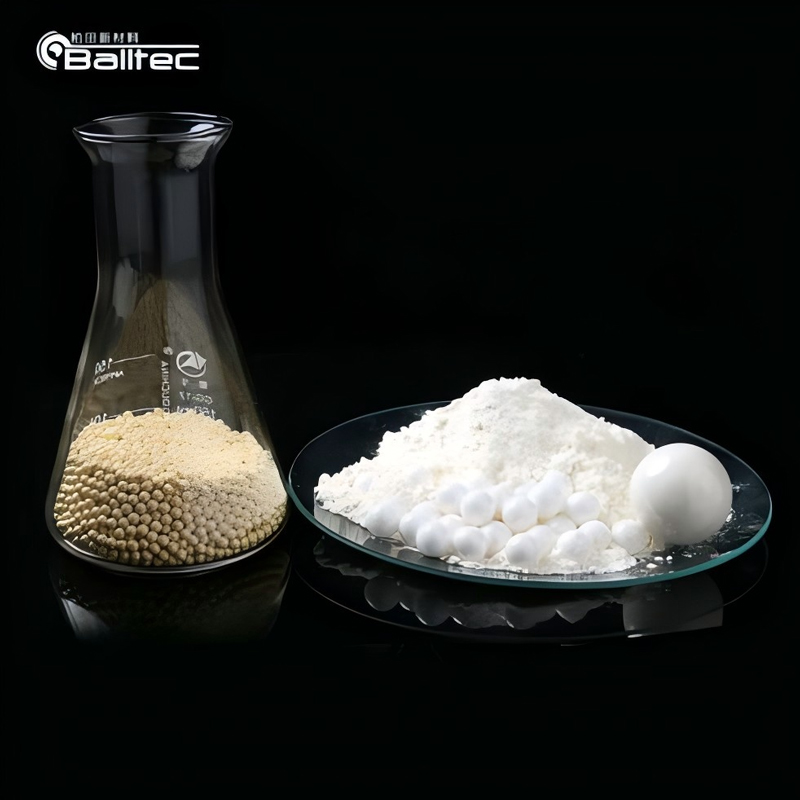

Alumina Ball Alumina bead High Alumina ball Al2O3 Grinding Ball

Applications

1. It can be widely used in the deep drying of petroleum cracking gas, ethylene propylene gas, hydrogen production, air separation unit, instrument air dryer and fluoride treatment in dioxygen water

2. It can also remove sulfur gas hydrogen, sulfur dioxide, hydrogen fluoride, hydrocarbon and other pollutants in the waste gas, especially suitable for the defluorination treatment of water containing fluorine.

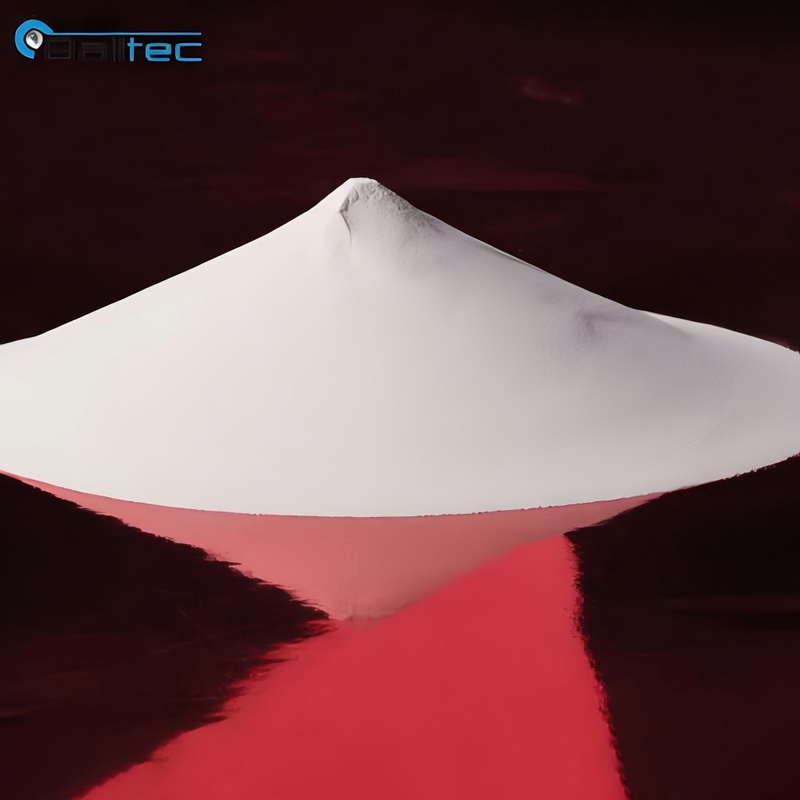

Activated alumina (molecular formula Al2O3-x(OH)2x, 0<x<0.8) is one of the most widely used inorganic chemical products in the world. Activated alumina has large activity due to its porous structure, high specific surface area and unstable transition state. It is widely used as catalyst and catalyst carrier in petrochemical and fertilizer industry. Activated alumina also has adsorption properties, so it is used as a desiccant of gas and liquid, an adsorbent for gas purification, a defluorination agent for drinking water, and a color and odor elimination agent for industrial sewage. The main industrial activated alumina products available today are produced by rapid dewatering. Activated alumina refers to calcined alumina after full fine grinding, with α-Al2O3 of primary crystal size 1μm as the basic composition (20% to 90%).

Regenerant using sodium hydroxide solution, can also use aluminum sulfate solution. The solution concentration of sodium hydroxide regenerant is 0.75% ~ 1%, and the consumption of sodium hydroxide can be calculated according to the 8 ~ 10g solid sodium hydroxide required for removing 1g fluoride, and the amount of regenerated liquid is 3 ~ 6 times the volume of filter material. The solution concentration of aluminum sulfate regenerant is 2 ~ 3%, and the consumption of aluminum sulfate can be calculated according to 60 ~ 80g solid aluminum sulfate for every 1g fluoride removed.

Specifications

| Model | Activated Alumina | |||||

| Shape | Sphere | |||||

| Chemical Composition | Al2O3 Content (%) | ≥93 | ≥93 | ≥93 | ≥93 | |

| Na2O Content (%) | ≤0.3 | ≤0.3 | ≤0.5 | 0.15-0.3 | ||

| Physical properties | Bulk density (g/ml) | 0.68-0.72 | 0.70-0.75 | 0.65-0.75 | 0.70-0.80 | ≥93 |

| Pore volume (ml/g) | 0.30-0.45 | 0.30-0.42 | 0.40-0.46 | 0.40 | ≤0.3 | |

| Physical properties Crushing Strength (N/PC) | Surface area (m2/g) | ≥300 | ≥300 | 260-300 | ≥300 | 0.72-0.78 |

| Active (%) | / | / | 56-62 | / | 0.30-0.50 | |

| Attrition loss (%) | ≤1.0 | ≤1.0 | ≤1.0 | ≤0.4 | ≥300 | |

| LOI (%) | ≤8 | ≤8 | ≤8 | ≤5 | / | |

| Static absorption (%) (RH=60%) | Water absorption | Fluorine absorption | Water absorption | Water absorption | ≤0.8 | |

| LOI (%) | 17-19 | 0.2-0.3 | 50 | 50-70 | ≤8 | |

| Φ1-2 (mm) Φ2-3 (mm) | ≥40 | ≥40 | / | / | Water absorption | |

| ≥70 | ≥70 | / | / | 17-19 | ||

| Crushing Strength (N/PC) | Φ3-5 (mm) | ≥120 | / | ≥120 | ≥120 | / |

| Φ4-6 (mm) | ≥150 | / | ≥150 | ≥150 | / | |

| Φ5-7 (mm) | ≥200 | / | / | / | ≥120 | |

| Φ6-8 (mm) | ≥300 | / | / | / | ≥150 | |

| Φ12-14 (mm) | ≥350 | / | / | / | ≥200 | |