01

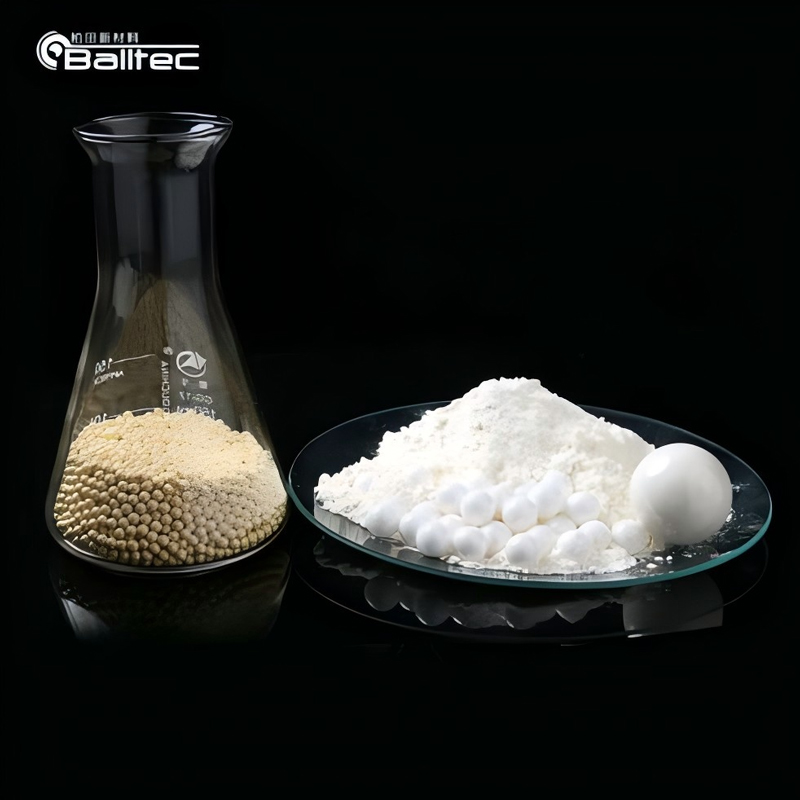

Activated Alumina Ball 2-4mm

Feature

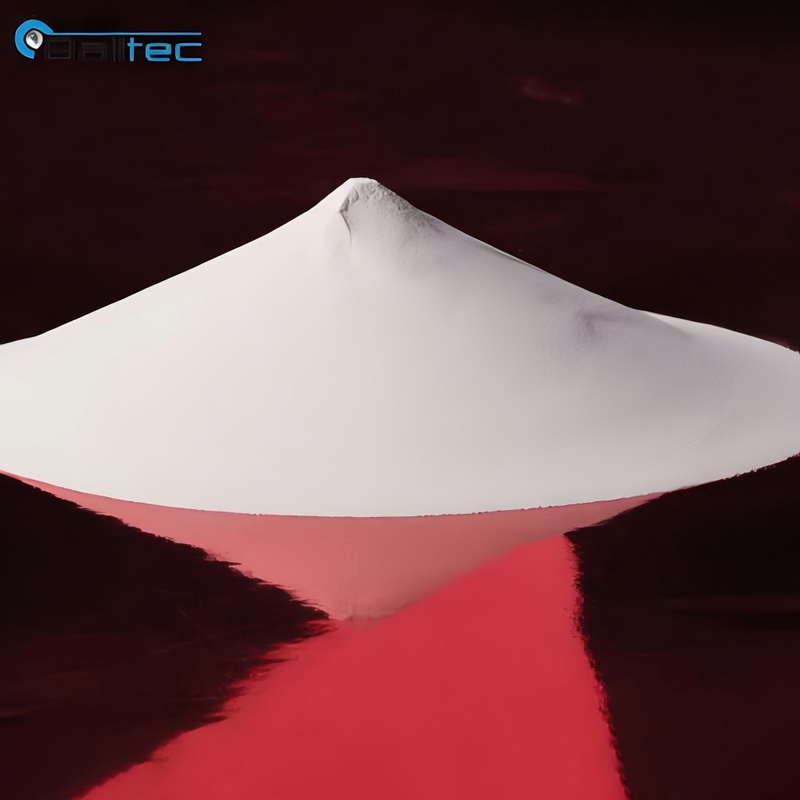

Because of its special process,microcrystalline nanostructures are reflected in the interior of the beads, andthey are homogeneous and compact.

A wide range of applications, especiallygrinding materials with high hardness.

Smooth surface, easy clean, less wear toequipment.

Chemical Content

Al2O3:92% ; SiO2 : 5% ; Others: 3%

Al2O3:95% ; SiO2 : 3% ; Others: 2%

Application

It is suitable for grinding and dispersingall kinds of vertical, horizontal sand mill, ball mill and other equipment.

Physical Properties

Density: 3.7

Bulk Density: 2.2

Hardness(Hv): 1100

Sphericity(%): 98%

Standard Size(mm): 0.3, 0.4,0.5, 0.6, 0.8, 1.0, 1.2, 1.5, 1.7,2.0, ~20, 30, 40, 50,60

Packing(kg): 25kg Plastic Drum/25kg Bags

Because of its high strength, high hardness, high wear resistance, large ratio, small size, high temperature resistance, corrosion resistance, no pollution and other excellent characteristics, high aluminum ball is widely used in different types of ceramics, porcelain glaze, glass, chemical and other factories of thick and hard material finishing and deep processing.

Taking 92% of the high aluminum ball as an example, its specific gravity (density) should reach more than 3.60, alumina content of more than 91.5%, low iron content. The same raw material, the same formula, the same firing temperature, the smaller the fineness of the powder after grinding the raw material, the higher the specific gravity, the better the wear resistance. The specific gravity of high aluminum ball is mainly affected by powder and burning, burning (not cooked), coarse powder, adding miscellaneous materials and other factors will lead to insufficient specific gravity of ball stone. The low specific gravity of the stone is not wear-resistant, easy to crack, but the high specific gravity does not mean that the stone must be wear-resistant, because the over-sintered stone can also reach a higher specific gravity.

Ball stone is the most important quality embodiment of wear resistance, some testing agencies can also do abrasion tests, these test reports can show the quality of ball stone, but the data is only for reference, because the laboratory testing environmental conditions and production environment is very different, the first test is water grinding, and many manufacturers are dry grinding; Secondly, many times the test is not put into other raw materials, but the friction between the stone and the stone, and the actual production process is to add a variety of raw materials. In the actual use of the process, to detect the wear of the ball stone, must do more records, after the initial ratio, by recording the number of added ball stone, combined with the output, calculate the wear of the ball stone in the production, so as to compare the cost of high aluminum ball and other grinding ball, can also compare the quality of the ball stone between the manufacturers. In addition to the hardness and fineness of the feed, there are also factors such as the grinding method (such as dry grinding and wet grinding), the speed of the ball mill, whether the ratio of the ball stone is reasonable, the viscosity of the feed and so on.