01

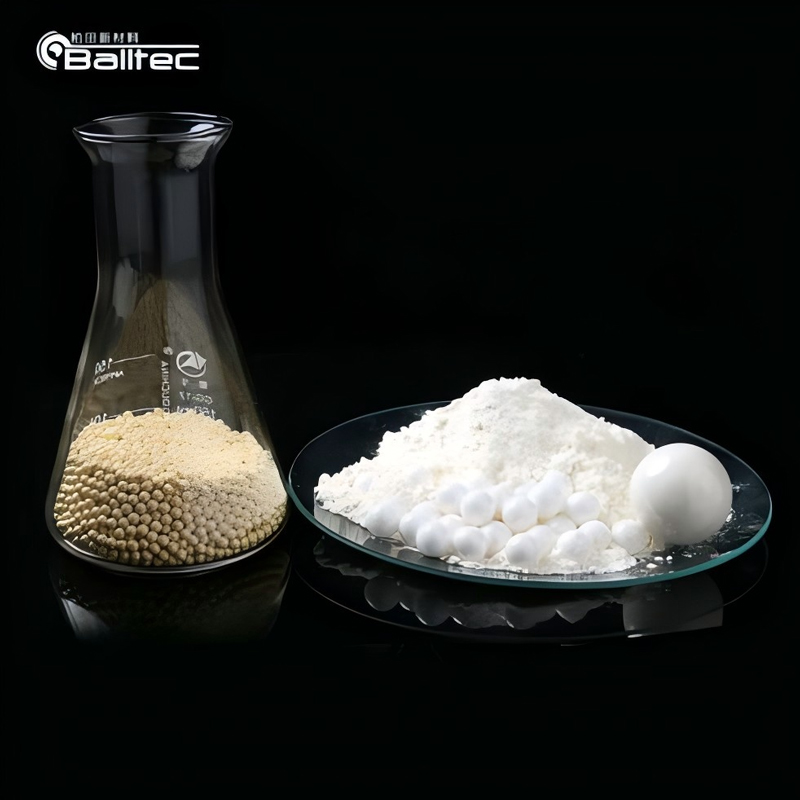

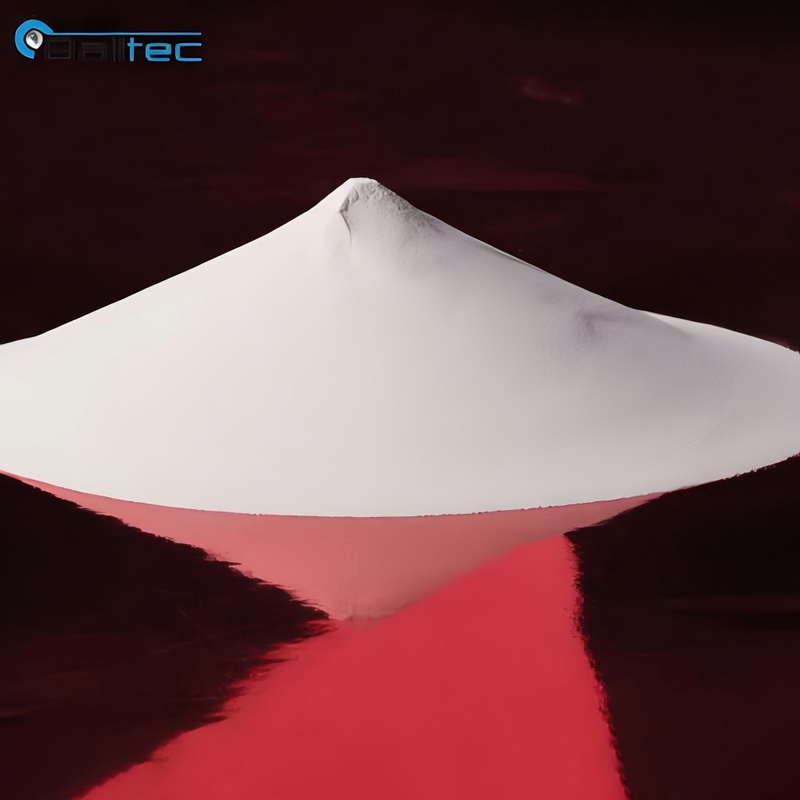

99.9% Al2O3 Grinding Bead Ceramic Grinding Media

Advantages and Disadvantages

Advantages:

High wear resistance: α-alumina crystal structure is uniform and fine, wear resistance is better than zirconia beads, long service life.

Corrosion resistance: acid and alkali resistance, high temperature resistance (up to 200℃ or more), stable performance in high temperature or corrosive environment.

Energy saving and environmental protection: the density is 2/3 of zirconia, and the filling amount can reduce energy consumption.

High purity: reduce impurity pollution, suitable for electronic materials, lithium battery diaphragm and other sensitive fields.

Cons:

High cost: Imported products are expensive (such as Japan Daming chemical product unit price of about 6000 yuan /kg).

Early technology limitations: early domestic products may have high wear problems, but through process improvements (such as nanocrystalline technology) have significantly improved performance.

Application industry

Fine ceramics and electronic materials: Used for crushing and dispersing alumina powder, electronic components, piezoelectric crystals, semiconductor materials.

Lithium batteries and new energy: As a coating material for lithium batteries, it improves heat resistance and insulation.

Optics and catalysts: Used for optical lens polishing, catalyst carrier and high temperature charge.

Coatings and chemicals: As a grinding medium for pigments and inks, enhance wear resistance and dispersion.

Methods of use

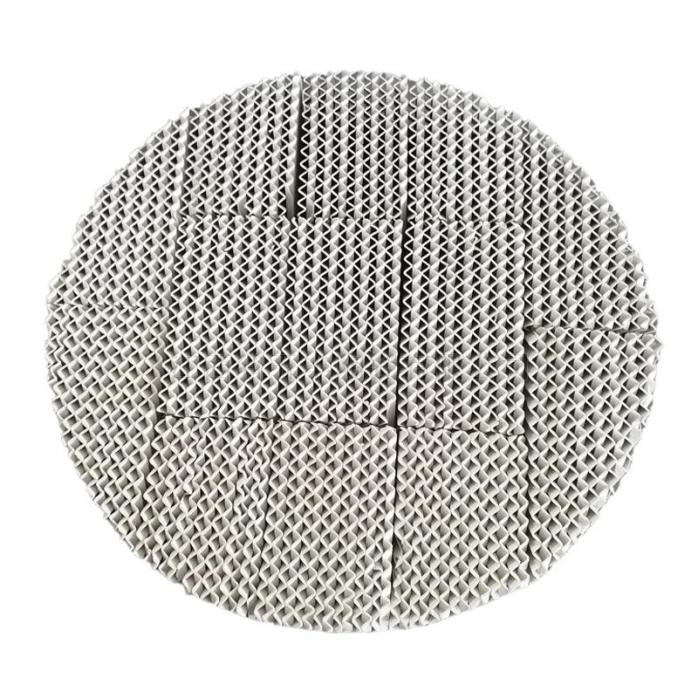

Applicable equipment: dry/wet ball mill, vibration grinder, stirring grinding tank, etc.

Size selection: Common specifications are 0.1-0.5mm (fine processing) or 5-25mm (conventional grinding), which need to be adjusted according to material characteristics and equipment requirements.

Operation suggestion:

When wet grinding, the slurry concentration is controlled below 60%, and the speed is recommended to be 7.8-12.6m/s.

The filling amount is about 2/3 of the volume of the grinding tank to balance energy consumption and efficiency.

Sum up

With its high purity, wear resistance and corrosion resistance, 99.9% alumina grinding ball has become the preferred medium for precision material processing, especially in the fields of electronics, new energy and high-end ceramics. Its application needs to be optimized in combination with specific process parameters to achieve a balance between high efficiency and environmental protection.