01

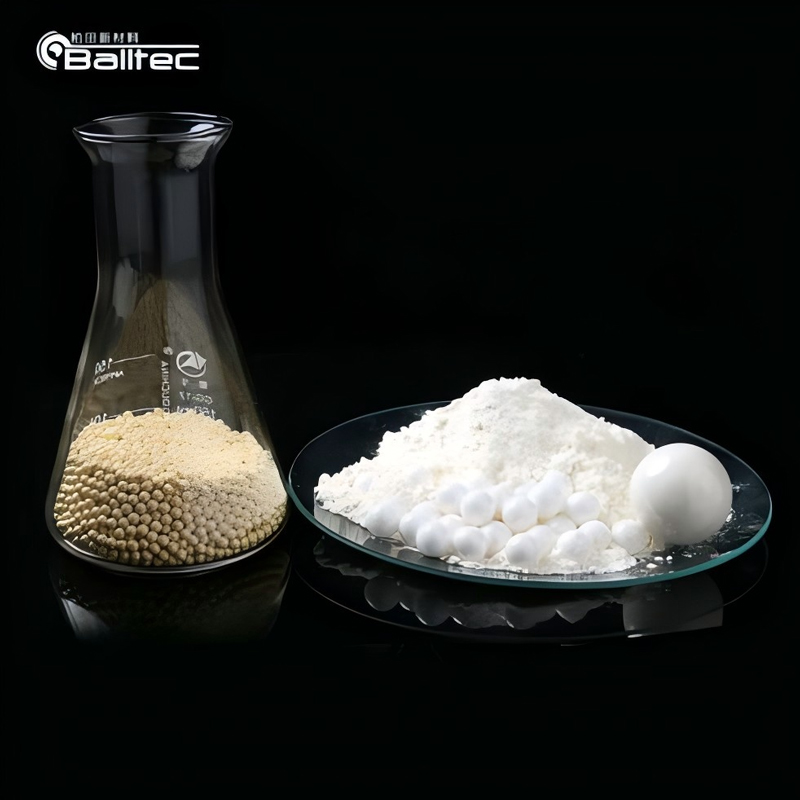

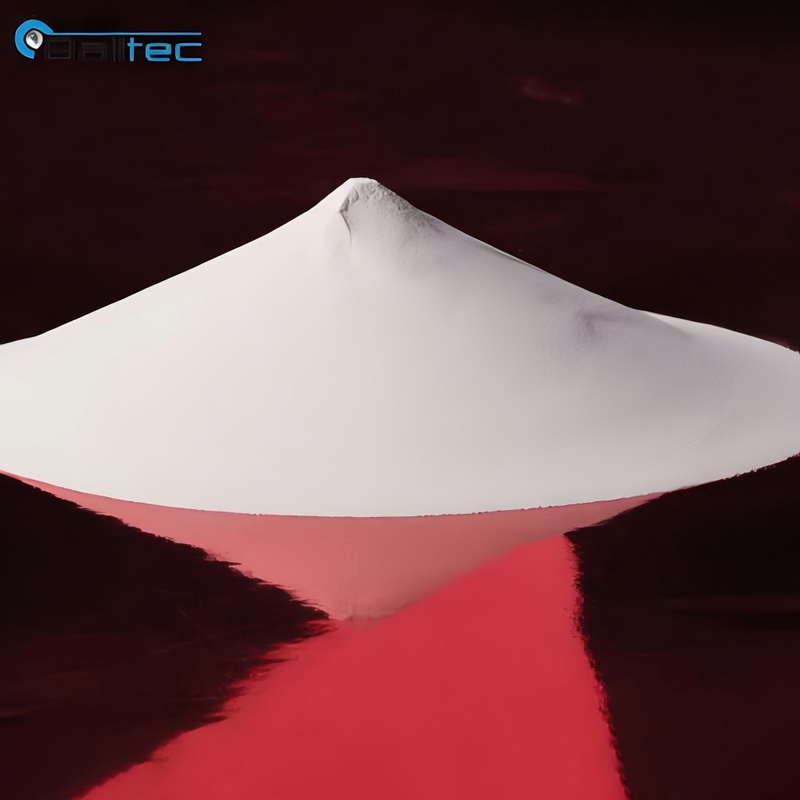

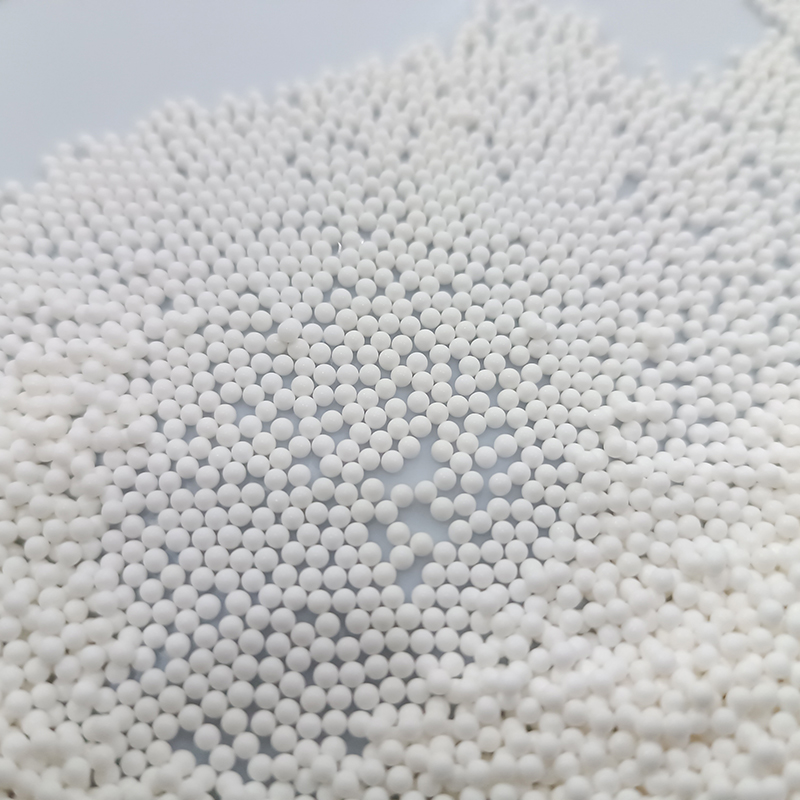

99% High Purity Alumina Al2O3 Grinding Ball Bead

Product Features

High purity and stability

The use of 99% purity of alpha-alumina (Al₂O₃), radioactive isotopes (such as U, Th) content is very low, suitable for sensitive to radioactive elements in the scene. Its crystal structure is uniform and fine, excellent wear resistance and long service life.

Physicochemical properties

Hardness: Mohs hardness 8.5-9, compressive strength up to 1800 MPa.

Corrosion resistance: Strong resistance to acid, alkali, high temperature water and other environments, stable performance when the slurry temperature rises during grinding.

Density and energy saving: the density is 3.8-3.93 g/cm³, about 2/3 of zirconia, reducing the amount of filling can reduce energy consumption.

Main parameters

Parameter range/numeric source

Purity 99%

Density 3.8-3.93 g/cm³

Compressive strength: 1100-1800 MPa

Wear rate wet ≤0.60%, dry ≤0.45%

Size 0.1-10 mm (customizable)

Application fields

Fine grinding and dispersion

Used for ultrafine grinding of electronic ceramic powder, sapphire crystal, lithium battery diaphragm coating.

Grind inks, pigments, coatings and other chemical materials to improve dispersion uniformity.

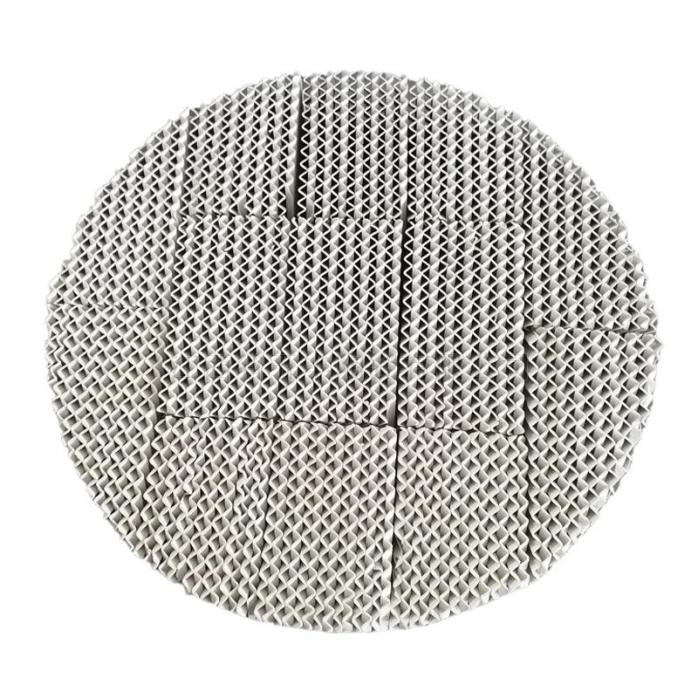

Industrial catalysis and support

As a catalyst carrier or reactor support material, suitable for chemical, pharmaceutical and other industries.

High temperature and corrosion resistance scenarios

Stable performance in refractory materials, high temperature furnace materials and acid-base environments (such as mines, cement).

Summary of advantages

Energy saving and high efficiency: low density reduces energy consumption, low wear extends service life.

Environmental protection and safety: high purity to avoid impurity pollution, suitable for medicine, electronics and other sensitive fields.

The above information is integrated from the industry technology webpage and the enterprise product description.