01

3A Molecular Sieve High Quality Desiccant 3A Zeolite Price Molecular Sieve Adsorbents for Gas Drying

Applications

- Drying of unsaturated hydrocarbons (e.g. ethylene, propylene)

- Cracked Gas Drying

- Drying of natural gas, if COS minimization is essential, or a minimum

co-adsorption of hydrocarbons is required.

- Drying of highly polar compounds, such as methanol and ethanol

- Drying of liquid alcohol

- Static, (non-regenerative) dehydration of insulating glass units, whether air

filled or gas-filled.

Specifications

| Model | 3A Molecular Sieve | |||

| Nominal pore diameter | 3 angstroms | |||

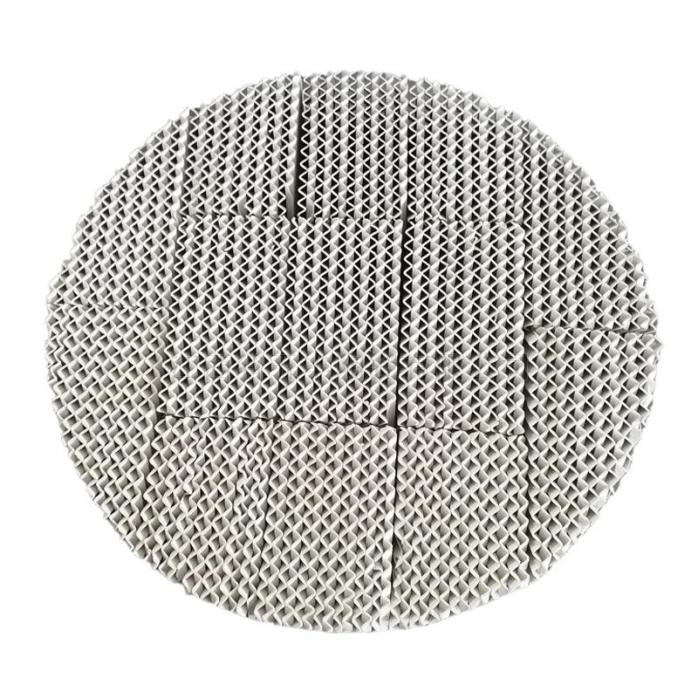

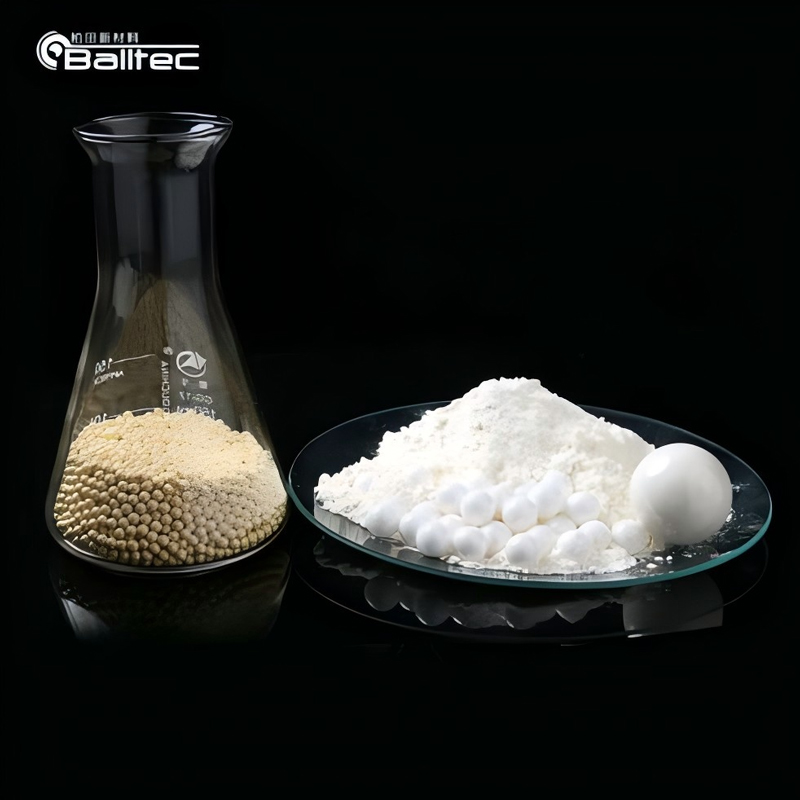

| Shape | Sphere | Pellet | ||

| Diameter | 1.7-2.5 (mm) | 3.0-5.0 (mm) | 1.6 (mm) | 3.2 (mm) |

| 8*12 (mesh) | 4*8 (mesh) | 1/16 (inch) | 1/8 (inch) | |

| Bulk density (g/ml) | ≥0.70 | ≥0.70 | ≥0.68 | ≥0.68 |

| Crushing strength (N/PC) | ≥55.0 | ≥85.0 | ≥30.0 | ≥50.0 |

| Size ratio up to grade (%) | ≥98.0 | ≥98.0 | ≥96.0 | ≥96.0 |

| Static H2O adsorption (%) | ≥21.0 | ≥21.0 | ≥21.0 | ≥21.0 |

| H2O content (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Wear ratio (%) | ≤0.25 | ≤0.25 | ≤0.25 | ≤0.25 |

The preparation of 3A molecular sieve usually involves the following steps:

Raw material preparation: such as water glass, solid aluminum hydroxide, sodium hydroxide, etc.

Solution preparation and mixing: water glass is boiled with steam to form an aqueous solution with a certain density, and impurities are removed by settlement; The solid aluminum hydroxide and sodium hydroxide are heated and dissolved in a certain proportion to produce sodium metaaluminate solution for use.

Gel generation and crystallization: water glass, sodium metaaluminate, sodium hydroxide are mixed according to a certain molar ratio, and after a certain reaction time under agitation, temperature is raised to crystallize, and crystal powder is obtained.

Ion exchange and activation: After filtration and washing, potassium chloride is added for ion exchange (the exchange degree is usually 40%), then filtration and washing, drying, adding adhesive kneading, molding, burning activation, and finally 3A molecular sieve is obtained.

FAQ

1. who are we?

We are based in Jiangxi, China, start from 2017,sell to South America(15.00%),North America(15.00%),Western Europe(15.00%),Eastern Europe(10.00%),Mid East(10.00%),South Asia(10.00%),Southeast Asia(10.00%),Eastern Asia(5.00%),Oceania(5.00%),Northern Europe(5.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

zirconia powder,zirconia bead,zirconia grinding media,alumina bead,ceramic bead

4. why should you buy from us not from other suppliers?

Professional Zirconia product with 20 years experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,

French,Russian,Korean,Hindi,Italian